As with Luisa Innocenti, who gave us her view of the mission in part one, Robin Biesbroek, e.Deorbit’s study manager, has been working on it from its infancy to conclusion. Robin took a few minutes to share his lessons learned, joined by Andrew Wolahan, a system engineer for Clean Space who joined the team shortly after Robin.

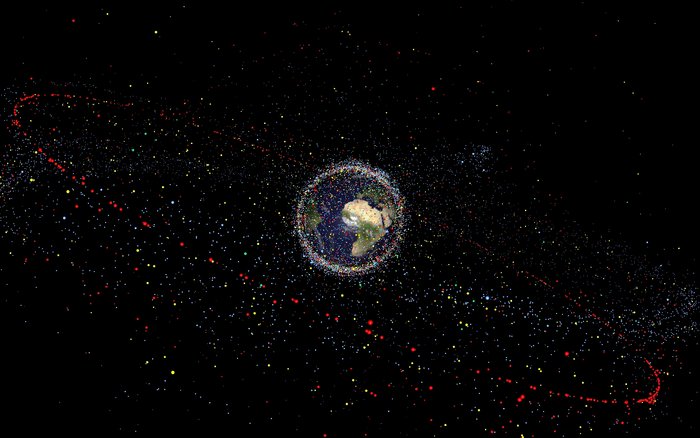

e.Deorbit began life in 2013, inspiring strong passion in all people involved in its conception. The objective was clear: ESA, like all space agencies, had a role to play in cleaning up debris from space. “It was not a choice, it was a must,” remarked the then ESA Director General Jean-Jacques Dordain. Doing nothing and letting the problem fester would at some point make it more difficult, and therefore expensive, to do anything in space. So, with the blessing of the Director General and ESA’s Director of Technology, Engineering and Quality Franco Ongaro, the e.Deorbit mission took shape.

This innovative mission was designed in an innovative way, harnessing model-based system engineering (MBSE) – meaning its development was focused on shared software models, rather than written documents. “We were the first to require the use of MBSE for Phase B1 of the entire mission design,” explains Robin, “including the physical architecture of the platform and payload together with the functional and logical architecture of the mission, with direct links to some of the tools used for simulations. Not only did we learn a lot about how to improve design using MBSE, industry really ran with the concept, and are today using it for a variety of other purposes.”

Read ‘Applying MBSE to a space mission‘.

The mission itself proved to be feasible, as Robin notes: “the main challenge is not technical – it is to get the money.” Despite the support of ESA and the European space industry, Member States were unwilling to finance its complete mission development. November 2018 marked the last of the mission’s final presentations.

One of the toughest challenges involved is the choice of capture mechanism to secure its target derelict satellite. It had to take into account that uncontrolled objects in space tend to spin. The e.Deorbit mission used Envisat as its case study, with a rotation rate as high as 2.8 deg/s. This appears to be an average spin/tumble rate for debris objects, although for some objects this rate exceeds 10 deg/s.

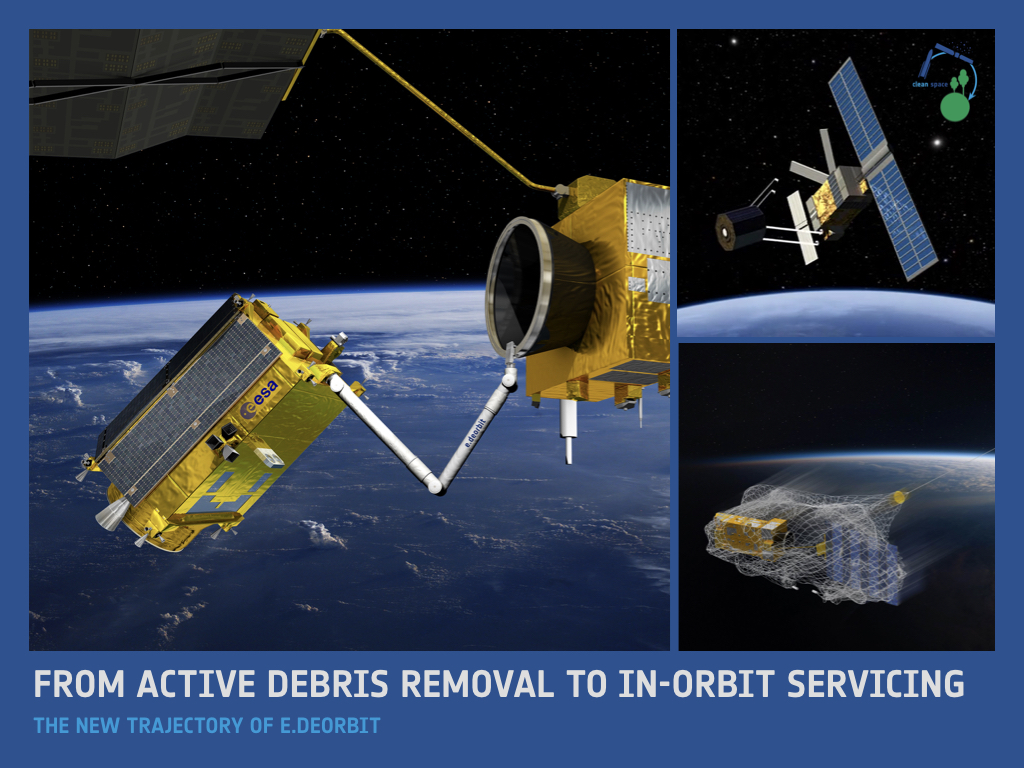

“With e.Deorbit we identified dozens of capture concepts,” says Andrew, “but prioritised three most promising technologies: a net, harpoon or robotic arm.” Nets and harpoons have the advantage that e.Deorbit can stay safely away from the rotating debris, up to 50 m distant, while performing capture. However these is a huge challenge in taking control of the combined capture spacecraft plus debris object just after capture. Andrew adds: “The stabilization is time critical to avoid ‘wrapping’ the tether around both satellites.”

The robotic arm gives a rigid connection, but the capture spacecraft would have to get within 2-3 m of its tumbling target before the arm could grab it. To do so the spacecraft would have to perform highly agile ‘synchronised motion’, requiring a complex and highly accurate guidance, navigation and control system.

Watch ‘Weightless net testing for derelict satellite capture‘.

[youtube https://www.youtube.com/watch?v=mx9Fb5sixBU]

In support of European industry, ESA is now continuing development of such a robotic arm, not only for active debris removal but also to perform multiple satellite servicing activities such as refuelling or tugging. The sheer versatility of the robotic arm makes it an attractive prospect.

Both Robin and Andrew look back fondly on e.Deorbit, and look forward to its various innovative aspects, from model-based system engineering to its grapple arm, being taken further forward.

Related content:

- Watch the video ‘e.Deorbit: the debris hunter‘

- Read more about

- Follow Clean Space on Twitter: @ESAcleanspace

Read other posts of the series ‘From ADR to IOS’:

Discussion: one comment

Very good! Lets go!