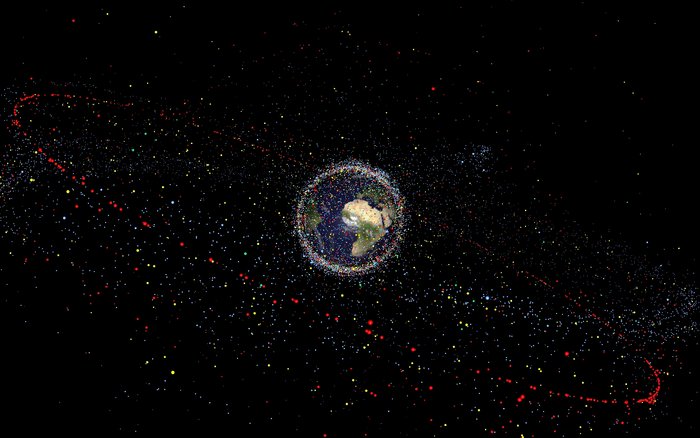

While recycling has become a daily activity on Earth, it is still uncommon to recycle in space. Yet thousands of defunct objects are in orbit and could, in theory at least, be recycled. ESA is developing a plan to make recycling in space a reality.

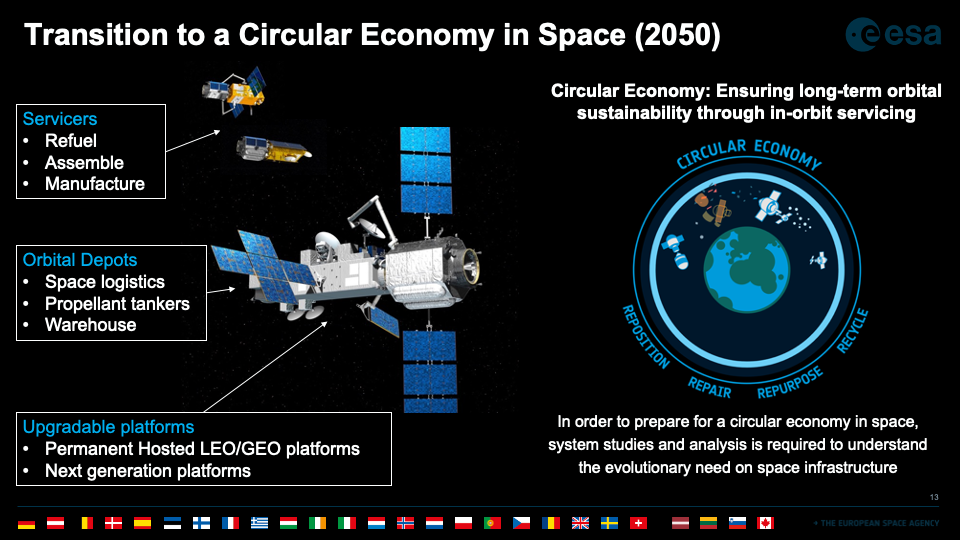

ESA intends to become space debris-neutral by 2030. Space debris neutrality means “adding zero net debris to the Earth orbital environment.” Our first step is to apply, by 2030, existing Space Debris Mitigation Requirements objects in low Earth orbit, with a probability of successful disposal well above the 90% currently required. Moreover, as a second step, the Agency is looking to foster the implementation of a ‘circular economy’ in space. In this case, a circular economy means “ensuring long-term orbital sustainability through in-orbit servicing.” In other terms, ESA seeks to recycle, refurbish, repurpose and reuse by 2050.

The first step toward these goals has been taken through a series of ESA studies carried out with European industry under the umbrella title of ‘On-Orbit Manufacture, Assembly and Recycling’ (OMAR). These studies identified some key advantages that this revolutionary new space ecosystem could have, including:

- Reduction in launch mass by taking advantage of material, equipment or even entire assets that are already in orbit.

- Reduction in raw materials that are required to be extracted on ground by recycling critical raw materials that are already in orbit.

- Decrease in development times as the assets can be developed and tested directly in orbit.

- Development of key technologies and capabilities that currently can’t be achieved because satellites are constrained by the dimensions and capabilities of launchers.

To transition from the OMAR studies to a circular economy, the Agency is considering presenting a proposal at the ESA Ministerial Council (end-2022) to place contract(s) with service provider(s)s and customer(s) to perform In-Orbit Servicing covering some or all services listed below:

- Cooperative Attitude and Orbit Control System (AOCS) takeover: lifetime extension for a customer spacecraft by providing the needed propulsion/actuation capabilities.

- Assembly: Assemble, manipulate and/or disassemble (take apart) spacecraft parts from or into a satellite/vehicle.

- Refurbishment: Rehabilitation or servicing of a spacecraft by replacing current aged or non-functional parts by new, equivalent ones.

- Manufacturing: Manufacturing of spacecraft parts in orbit starting from raw material and/or basic components coming from Earth and/or from in-orbit recycling.

- Refuelling: Re-supply of propellant to a spacecraft already in space.

However, if it is possible to perform these services in space, what about recycling?

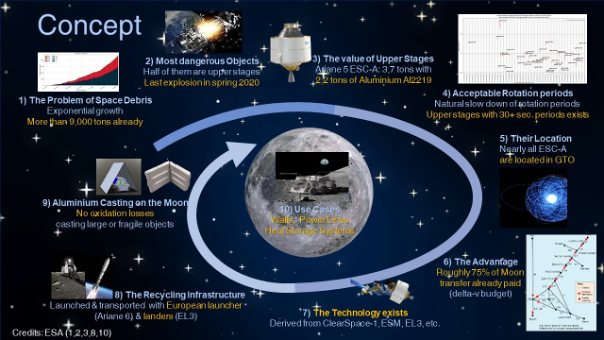

A recent study investigated the feasibility of recycling in space. Even if the study, run by Orbit Recycling, focused on recycling on the Moon, some of its findings may be generalized to space in general as it addresses the challenges of recycling in space.

The study substantiates the idea that recycling space debris is within the framework of Europe’s technical capabilities. The recycling of raw materials for space manufacturing seems to be the initial ‘low-hanging fruit’ and objects with high aluminium content are ideal recycling targets.

As space agencies around the world express their interest in a lunar ground station in the Global Exploration Roadmap (GER), the demand for construction material on the Moon is a given. The study finds that supply through the recycling of space debris could avoid costly material transport from Earth’s surface and could act as an interim solution until lunar In-Situ-Resource-Utilization (ISRU) technology becomes available. It estimates the price to be €150,000 per kilogram of recycled aluminium on the Moon, and considers that this amount would be at least cost-competitive with sending this material from Earth.

The concept of space debris recycling is summarized in the following graphic, and the Orbit Recycling study itself describes each aspect in detail. It starts with the selection of the most suitable space debris objects for recycling based on weight, composition, accessibility (e.g., orbit, potential tumbling rates) and the number of equivalent items available that would achieve scaling advantages.

The results of preliminary ground observation of selected space debris items to validate their orbits and tumbling rates were presented to ESA during the final presentation of the study. The observations were provided by Orbit Recycling’s partner, the CastelGAUSS Observatory, Italy, and the Fraunhofer FHR TIRA radar, Germany; general risk reduction due to the removal of debris for recycling is discussed. A precursor mission idea is described to validate the identified tumbling rates with a small satellite and to visually inspect the selected debris item.

The study provides a brief overview of possible detumbling technologies for space debris items, as well as a summary of existing ‘gripping’ technologies. Various concepts for a recycling space tug mission are presented, including a Vega-C-launchable design, starting in LEO, as well as an Ariane 64-launchable design, starting in GTO. A simplified analysis of the proposed Moon landing and impact scenario is described, including the results of a lunar surface debris recovery mission concept. Finally, an overview of aluminium smelting and casting in regolith processes is given, including the concept of concentrated sunlight sintering and melting via Fresnel lenses.

Additional research is certainly needed to mature the concept presented and to close certain capability gaps. However, since most of the required technology already exists or is currently being developed for other missions, many synergies could be exploited to reduce the levels of investment needed. What’s still missing is the political will to ‘turn waste into value’.

It seems that recycling in space could become a reality in the next decades. The remaining question is: when?

Related links

- Space Debris Mitigation policy for Agency Projects

- ESA is looking into futuristic in-orbit services: recycling satellites

- New request for Information on in-orbit servicing released by ESA

- The executive summary of the study “Analysis of space debris recycling potential to supply raw materials for constructions on the Moon” is available on the ESA Nebula Public Library

Discussion: 3 comments

Why is this blog not available in German?!

We’re running this blog on a best-effort basis. Thank you for your understanding

I don’t see anything on the page its just blank only images