Megaconstellations are being proposed as new space systems consisting of hundreds to thousands of individual satellites. Each constellation is designed so that all individual satellites work together to provide capabilities, such as broadband, on a global scale. These systems require new radical approaches to the design and operation of a satellite.

Mega Constellations – Image created with SaVi

An Evolution in Manufacturing, Assembly and Testing

The development of these systems calls for an evolution in satellite manufacturing, assembly and testing methods. For instance, if a system consisting of 1000 satellites is to be launched within a 2-year period, the satellites need to be manufactured at an unprecedented rate for the space industry. Potentially in the order of a few satellites per day may have to go through the manufacturing, testing and assembly process.

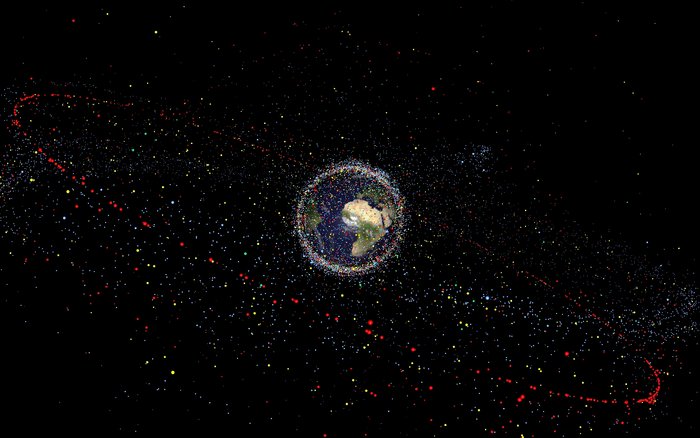

High Reliability for End-of-Life Operations to Protect the Debris Environment

With the debris environment becoming ever increasingly populated, the notion of launching a single system consisting of a 1000 satellites will drive the need for satellites that are very reliable in terms of meeting the space debris mitigation (SDM) requirements. Without a high level of compliancy, we may see in the near future a significant increase in the debris population due to in-orbit failures , or due to satellites that are unable to perform their End-of-Life disposal manoeuvres currently required to see the spacecraft vacate protected regions around the Earth.

Innovative Automation Level

Traditionally satellites have a limited level of automation whereby they execute commands that are pre-planned or sent from ground directly, generally with the assistance of man-in-the-loop. But for megaconstellations such an operations philosophy would require a very large workforce. Hence, megaconstellations may need to be capable of executing adaptive mission operations on-board for certain tasks, and for others, such as Collision Avoidance Manoeuvres (CAMs), a combination of on-board autonomy and on-ground automated processing. Depending on the size and orbit of the megaconstellations, up to 100,000 CAMs may be required per year, more than two orders of magnitude higher than what is currently done.

Sustainability of the Service

Consideration should also be given to environmental impacts on Earth itself arising from these constellations. However, whilst the manufacture, launch and operations of constellations of hundreds of satellites will no doubt impact the environment, it may be the case that due to the shift from classical methods of satellite production to novel, more automated methods, the environmental impact per mass of satellite inserted into space is reduced.

The deployment of megaconstellation systems will drive the need for new manufacturing processes and testing philosophies at a time when the orbital environment is becoming increasingly cluttered with space debris due to satellite failures/break-ups and in-orbit collisions.

To safeguard Earth’s orbit, megaconstellation systems will need to implement technologies to minimise the systems potential impact on the debris environment, such as those under the initiative of CleanSat and may even need to consider the future removal for those satellites within the constellation which have failed to perform the end-of-life manoeuvres.

Discussion: one comment

Hi Jessica,

I want to use a quote of this post in the introduction of my bachelors thesis. I just need your surname to make it a valid source.

Please answer me, as I only have time until tuesday.

Thanks in advance,

Lennart