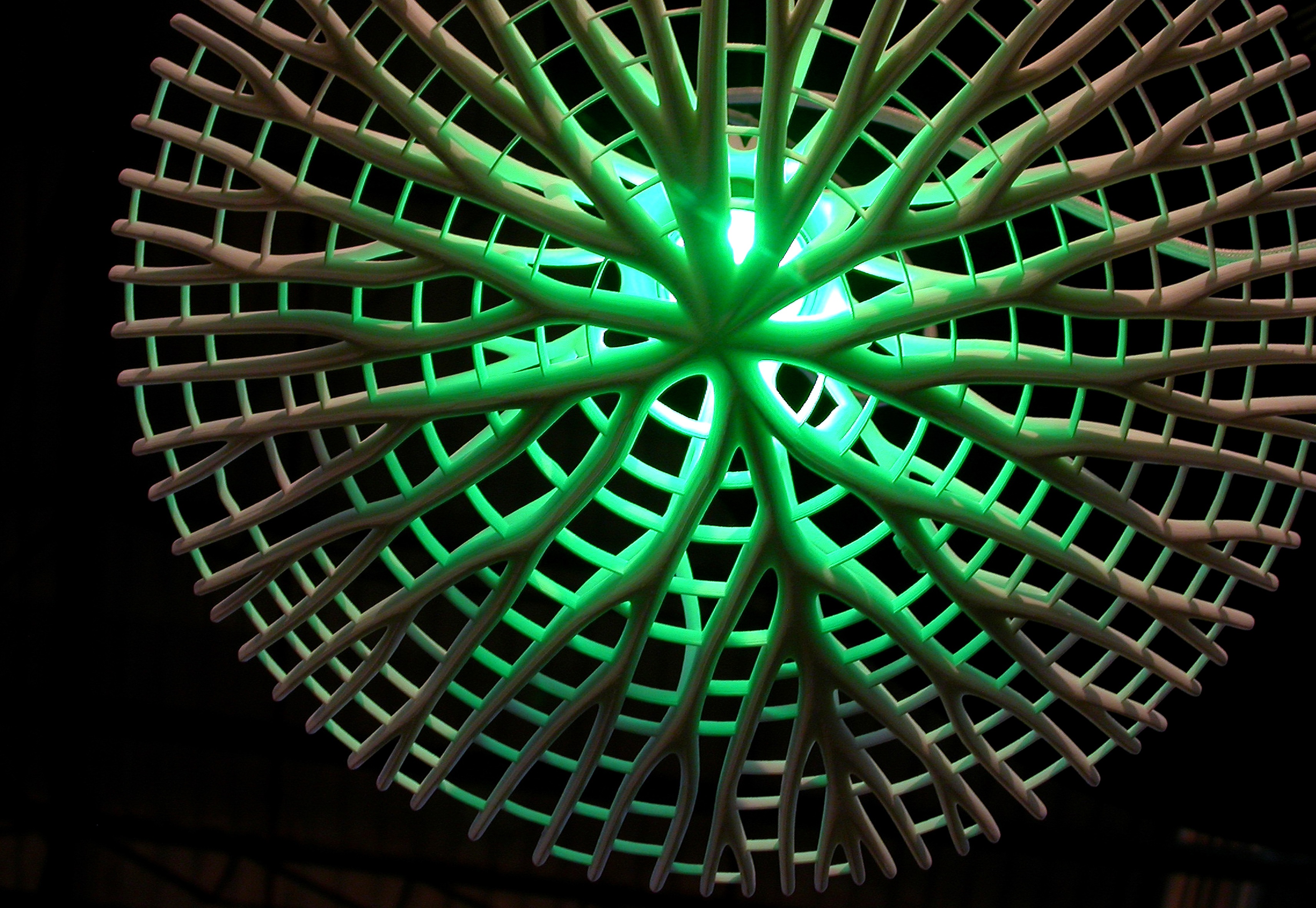

3D printing technologies are amazing. They allow you to manufacture pieces that you would not have dreamed of. Why? Simply because the parts that you digitally design are cut into hundreds of layers, micrometres thin and then the ‘printer’ will deposit very thin layers one after the other.

This could be considered as a heavy process but actually it has many advantages. Let me tell you about a few of them. First of all, raw material is easy to get access to and ready to use. Then, you don’t produce waste. This also means that you reduce the recycling costs. Your freedom to design is much higher than when you use current manufacturing processes. Indeed, you do not cut from the bulk block.

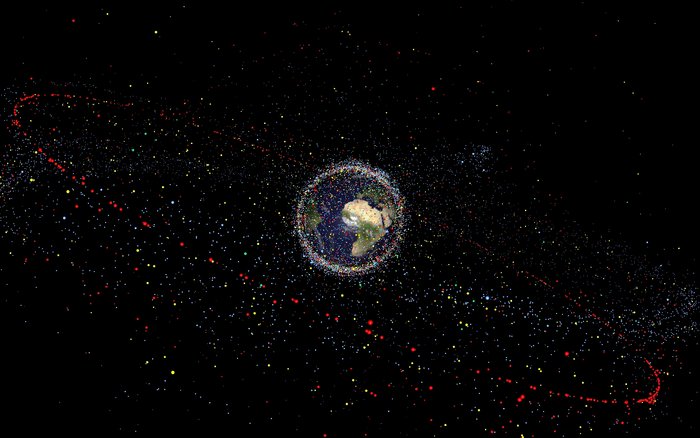

For these reasons, ESA has been investigating the different 3D printing technologies. It found out that producing some space technologies through additive manufacturing (another fancy word which also means 3D printing) could lead to a mass saving of up to 50%. And this would not impact the performance of the piece!

Some of these pieces are already flying on commercial satellites and others are under qualification for ESA missions. Many more will be developed in the coming months/years. Obviously, we are now looking forward to a fully 3D printed satellites. In a few decades maybe?!

Discussion: no comments