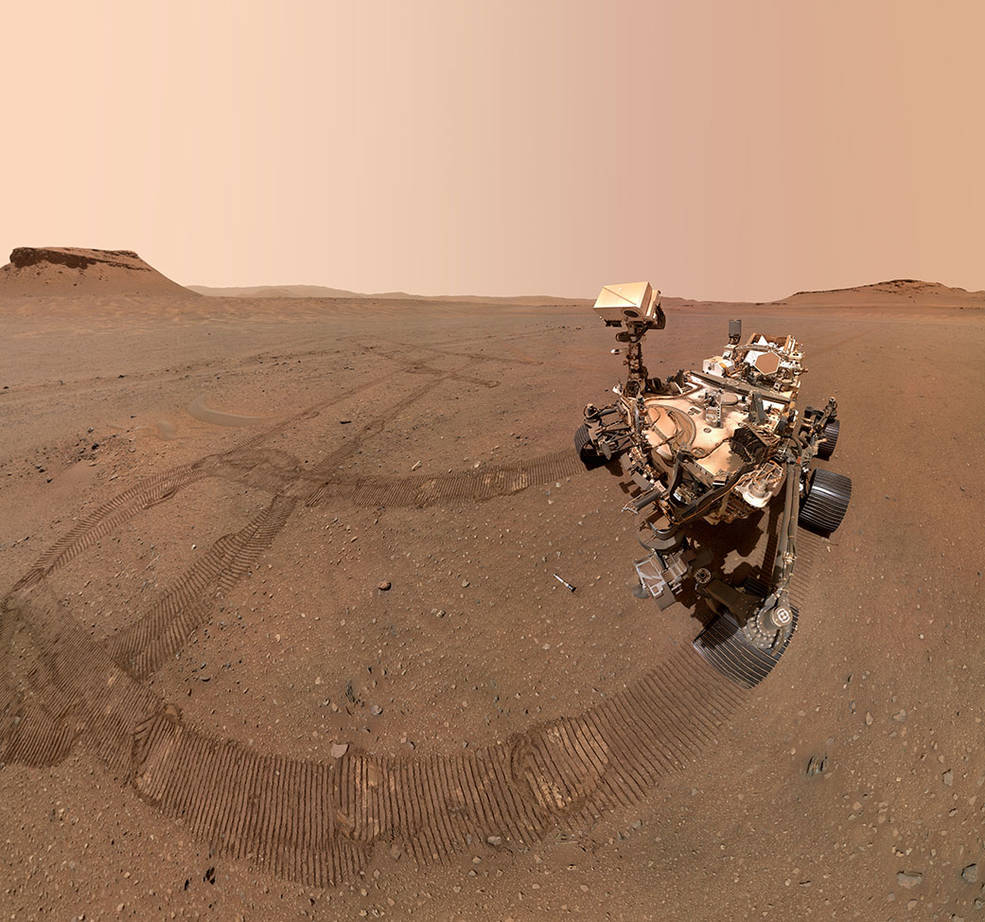

While NASA’s Perseverance rover is hard at work scouting the Red Planet, European engineers are working to perfect the robotic arm that would collect the tubes and insert them on a rocket for the trip back home.

This video shows a prototype mastering the pickup of a tube from a sandy surface. The robotic arm uses its jaws to grip the target from various angles and positions, firmly but with caution so as not to damage the precious load. Inside the tube, the real samples on Mars weigh a few grams and are about the size of a piece of classroom chalk.

Pickup operations of sample tube with a robotic arm prototype. Credits: AVS

This model is the first hardware developed to consolidate the design of the Sample Transfer Arm, a 2.5 metre-long robot that will load the sample tubes into a lander for delivery towards Earth.

The “hand” of ESA’s robotic arm, or end effector, is designed to pick up tubes either from the rover or from the ground. The robot uses a replica of the hermetically sealed sample tubes that the Perseverance rover is leaving on Mars. These cylinders are called RSTA, short for Returnable Sample Tube Assembly. Beyond the acronym, to most people on Earth they look like… lightsabres.

At the Added Value Solutions (AVS) facilities in Spain, the challenge was for the arm to master its close grip on a tube on the ground. For this pickup operation the arm uses two fingers that grip the tube tightly. A closing mechanism avoids excessive forces that could damage the tube.

As with many missions in space, there are contingency plans in place. In the best scenario, Perseverance reaches the lander and offers the tubes, ready for direct pick-up by the Sample Transfer Arm. This operation involves an additional mechanism: a plunger to extract the tube from the rover and move it around safely, to then insert it into an orbiting sample container that will be returned to Earth.

The backup scenario foresees two Ingenuity-like helicopters collecting the tubes from a depot – the first sample depot on another world – and dropping them in front of the lander. This is exactly what is being trained for at AVS, picking up tubes from the ground.

On Mars, this action would be a plan B and involve the collection of 10 tubes dropped by Perseverance.

This European technology is part of the Mars Sample Return campaign, a joint effort by NASA and ESA set to be the first to deliver scientifically selected samples from the Red Planet to Earth in the 2030s. Once safely back on Earth, the unique samples will undergo extensive analysis in the world’s best laboratories using state-of-the-art equipment and techniques.

Discussion: one comment

That’s great option but i heard this is very expensive. But it is worth 🤗. Im really wonder what result of the tests will be… Is some life or not on the Mars? 🤔

Vicky Hancock