Shumit Das is a structural engineer working for ESA’s technology department in The Netherlands. We asked him a few questions to get to know the people behind Orion and Artemis

What does a structural engineer do?

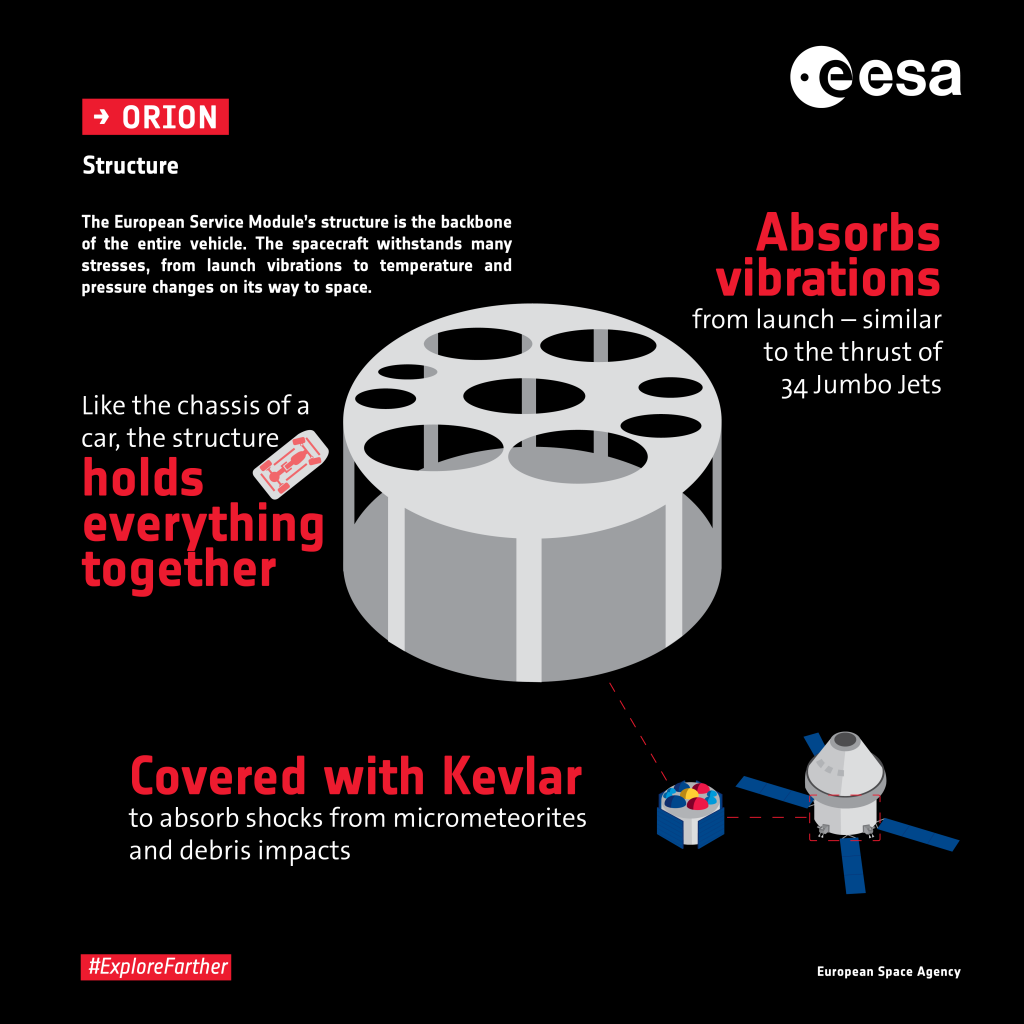

Structures are any part of the spacecraft or launcher that holds everything else in position and must resist the mechanical or thermal loads during the entire life of that mission.

A structural engineer is the focal point within the Agency for spacecraft and launcher structural design and verification. For the Orion programme, we check that everything about the structure is made properly by our suppliers and can resist space environments and loads.

If the structures don’t work as expected, this could cause parts of the vehicle to stop working, or even break, which would cause the mission to fail. Our role is to ensure that the vehicle and the astronauts using it are kept safe at all times by the structure around them works as intended.

How do you do it?

As a structural engineer, I am one of a team of experts that support Gandolfo diVita, who is the senior structural engineer on the Orion European Service Module programme.

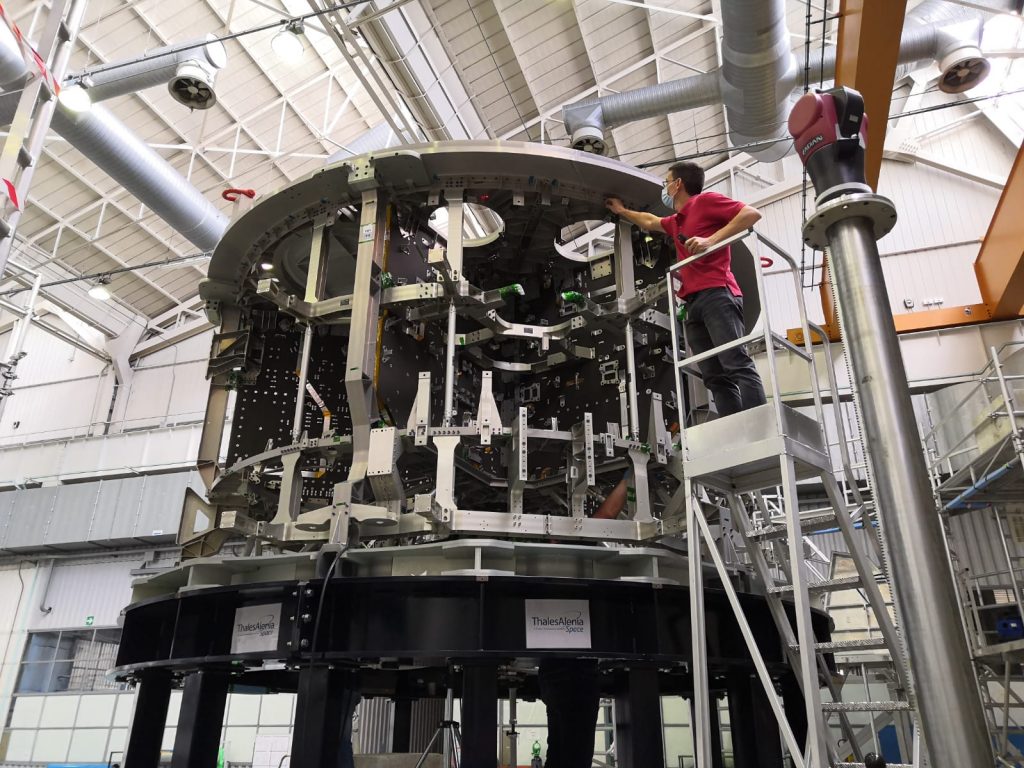

We keep an oversight of all the structural analysis and experimental testing that is done by the supply chain, to ensure that everything that is part of the structure on the European Service Module is designed in compliance with the specifications and safety requirements set by ESA, and that enough tests are done to prove that all the parts that are manufactured do behave as expected from the design.

For Orion, the team of Structural engineers is in frequent communication with the project management and also other ESA teams that depend on the structure for their parts of the system to function, such as Propulsion and Thermal teams. We are often in contact with Structural engineers from the Prime supplier Airbus and other teams to support them in solving technical issues, either in the design and verification, or sometimes when errors occur during the manufacturing.

In my case, I have specific experience in design and verification of composite materials, such as carbon fibre reinforced plastics (CFRP). This can be a very good way of providing structures that are light yet stiff and strong, but have to be manufactured very well for them to perform as required. They are somewhat more fragile than metals and have to be protected from impacts and other damage. Amongst other tasks, I lend the Orion team my experiences gained in the aircraft industry on how to manufacture and use composite materials in a safe and effective way.

Part of our time is also spent in encouraging development of new types of materials, processes and applications in Europe, through ESA funded Research and Technology activities, such that the Structures test and verification activity can be improved in the future. For example I proposed and launched an ESA R&D activity to mature non-contact inspection techniques for parts made of composite materials. This work is particularly exciting because it gives a chance for me to contribute to improving things for the future instead of just repeating what is tried and tested before.

What are you most proud of in your work?

I always wanted to join the space industry and have some involvement in exploring other planets, so I’m proud of the fact that I work in such a multi-disciplinary team of people, from many different nationalities, all working together to solve technical challenges. It’s really motivating to know that the work makes a difference to whether we can put humans back on the Moon or even on Mars.

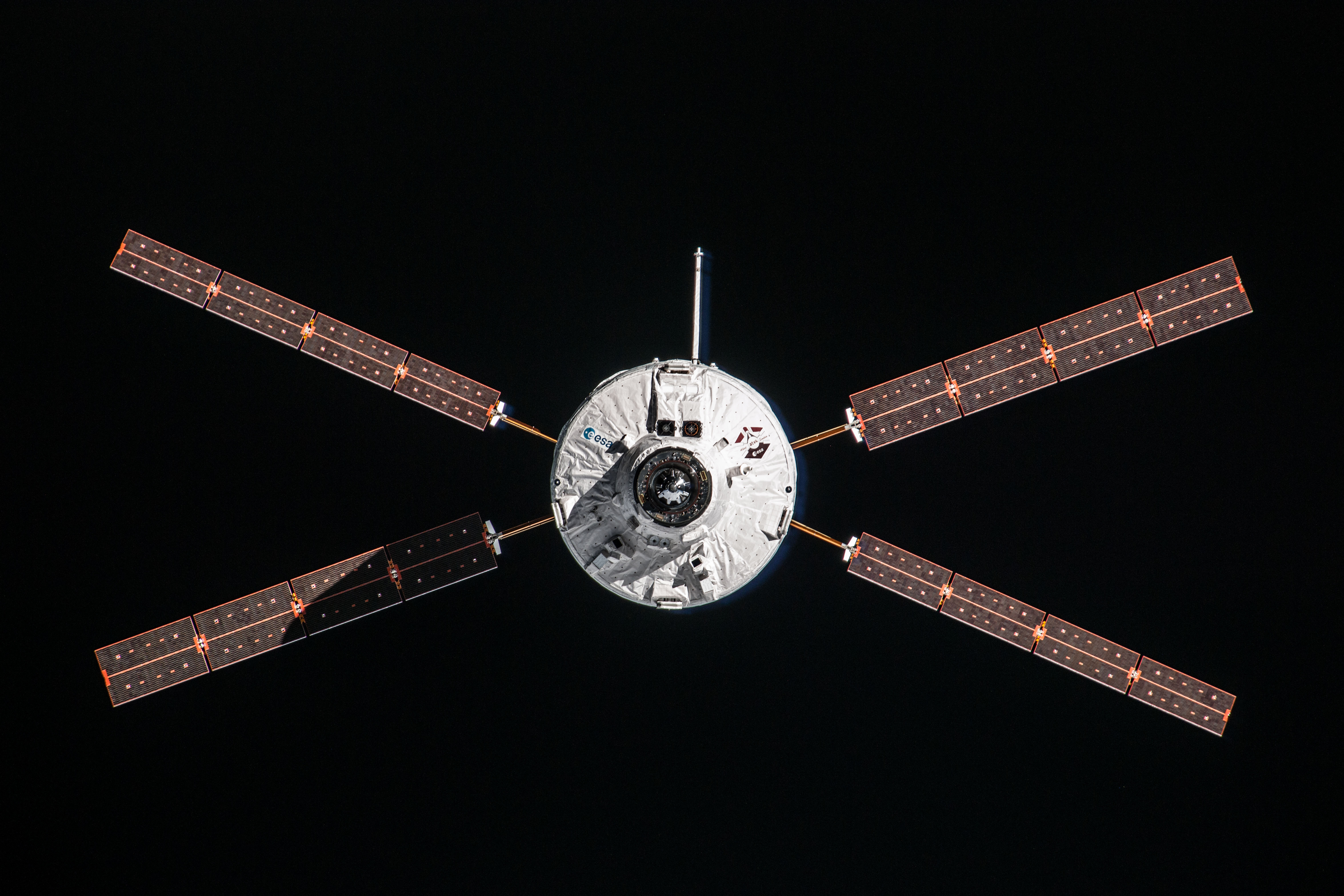

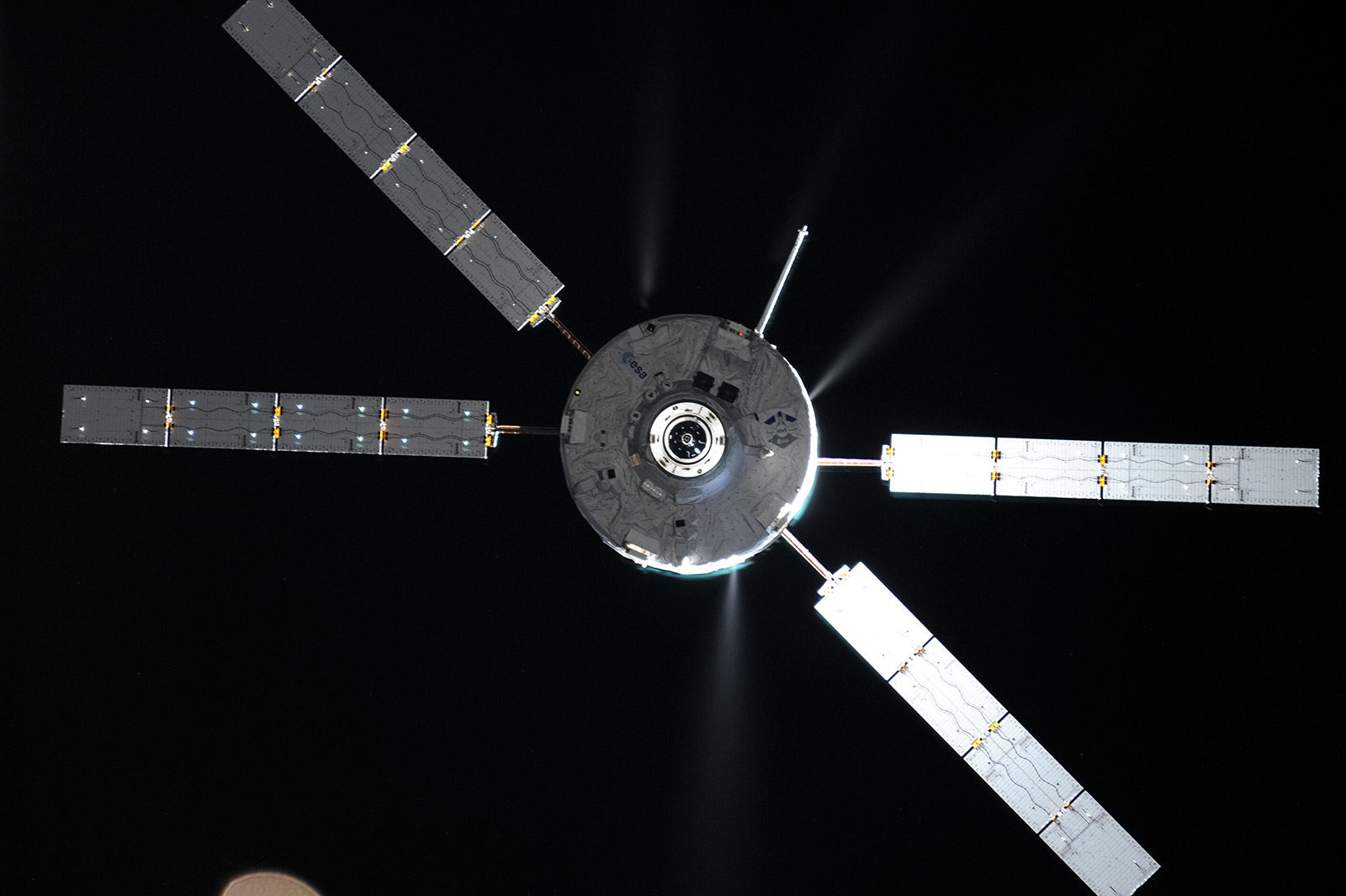

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: no comments