An important piece of ESA hardware for building and testing the Orion spacecraft was formally handed over to NASA this month. The Propulsion Qualification Module was built in 2016 in Sweden by OHB to test and ensure the fuel and thrusters work as designed on humankind’s next-generation lunar spacecraft.

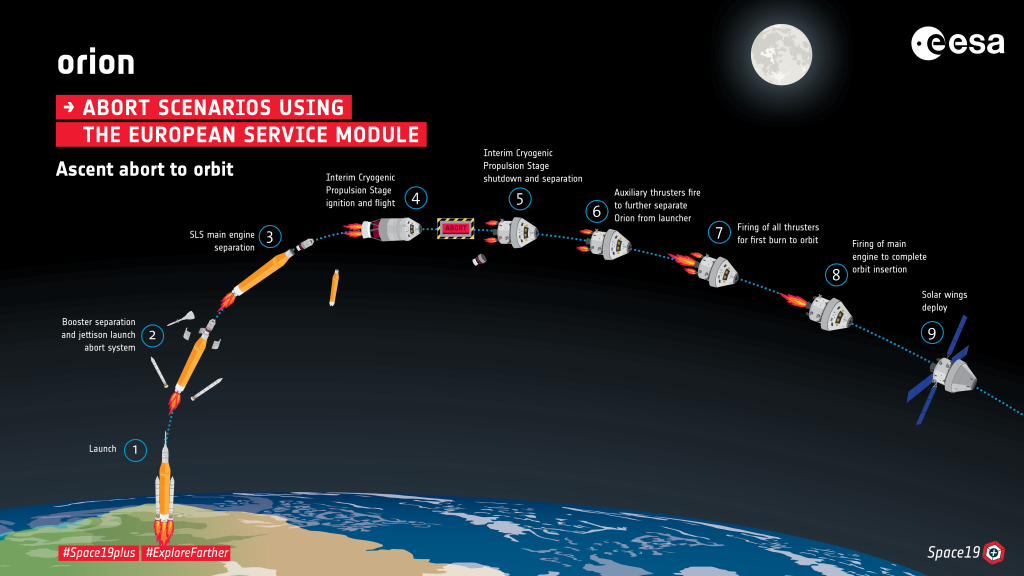

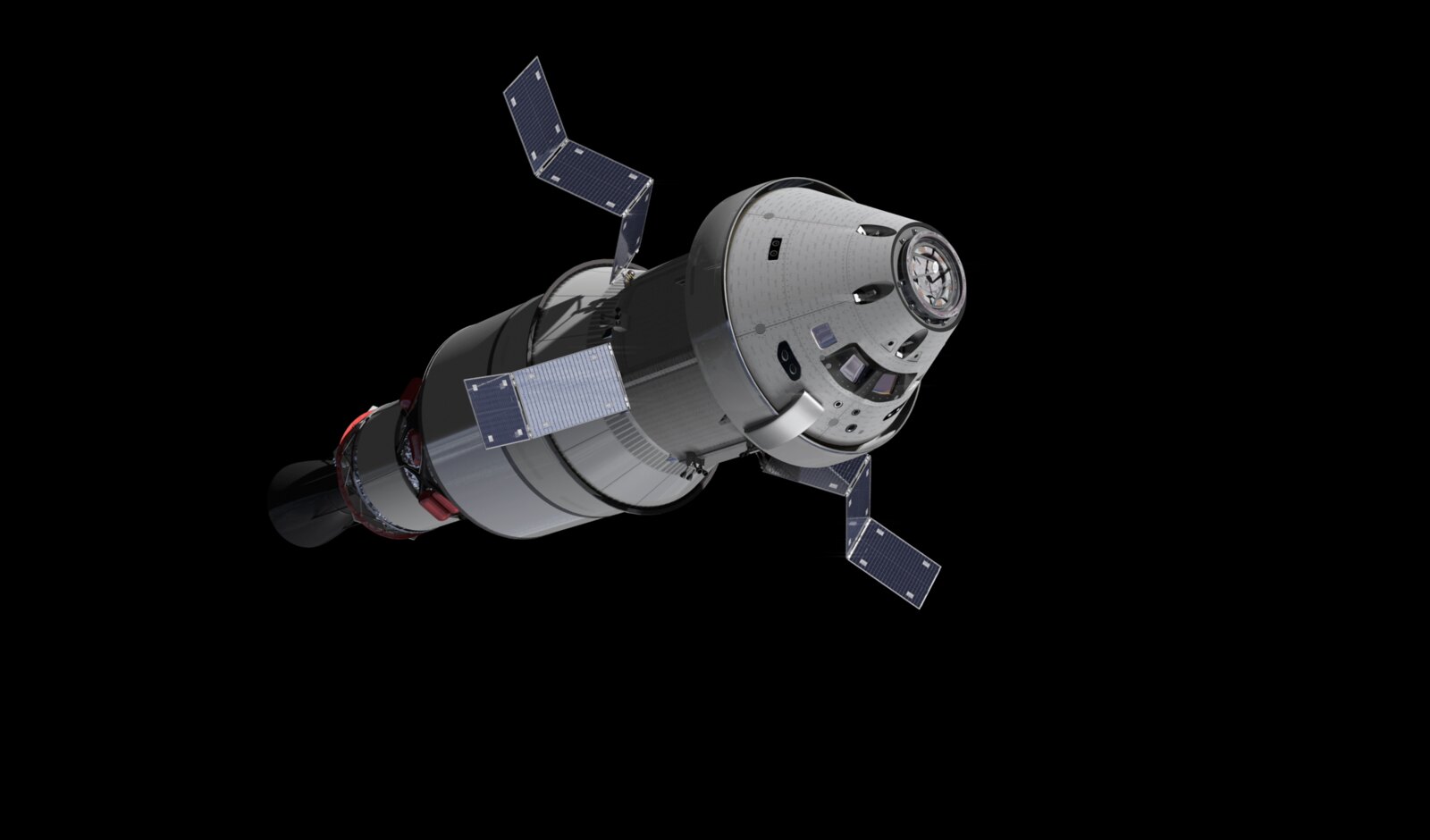

Orion is the spacecraft that will ferry astronauts to the Moon and the lunar Gateway for the Artemis programme, with the European Service Module providing the power, thrust, water, air and fuel for the astronauts in the crew module.

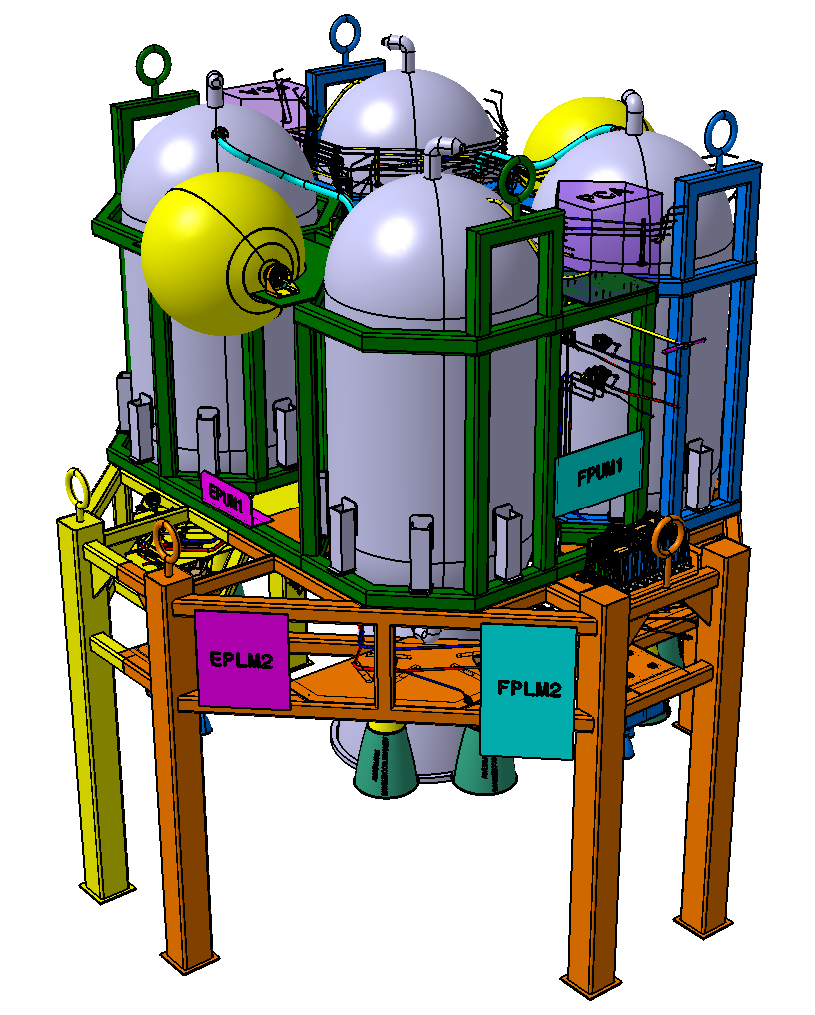

Although the Propulsion Qualification Module (PQM) will not go to space the model serves an important role in development: ensuring everything works as planned. The full model is roughly a 4-m cube made out of stainless steel and provides the full components for testing the thrusters, fuel lines and firing of Orions engines.

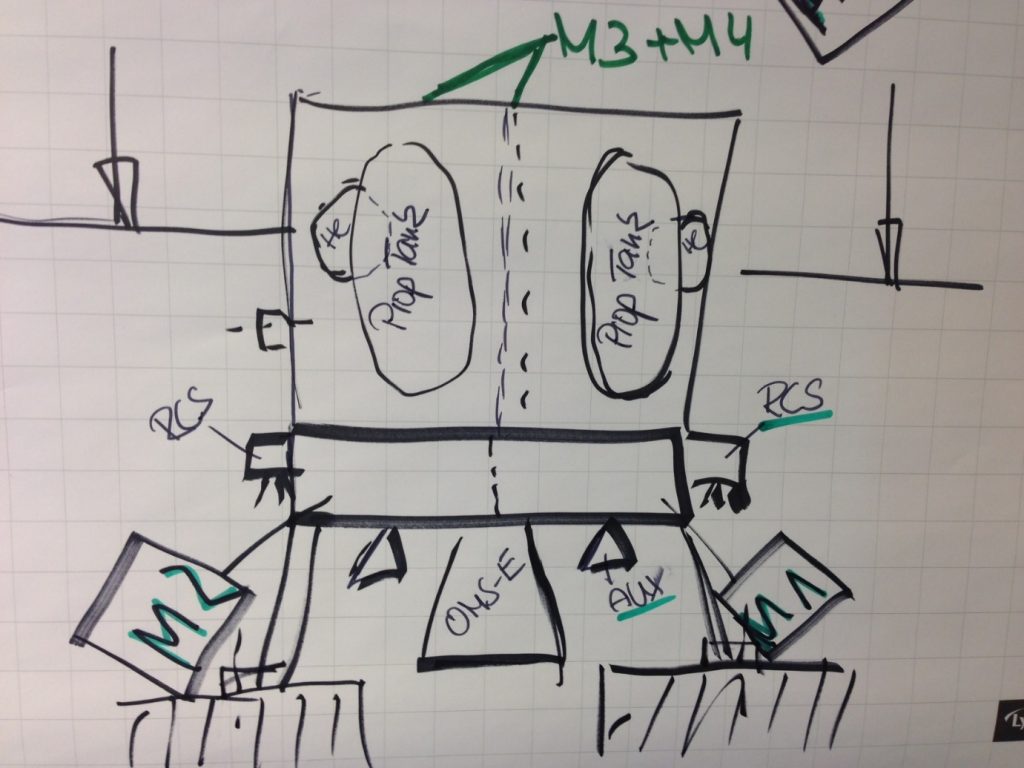

The model has four 2000 l tanks with walls 1 cm thick. The tanks hold mixed oxides of nitrogen (MON) and monomethyl hydrazine (MMH) – two tanks for each propellant. They are pressurised at 25 bar with a total capacity of nine tonnes . Other elements of the PQM include two high-pressure helium tanks; pressure-control systems; the sensing and command system with drive electronics; the propellant lines with shut-off valves; filters; and of course engines that will propel and orient Orion.

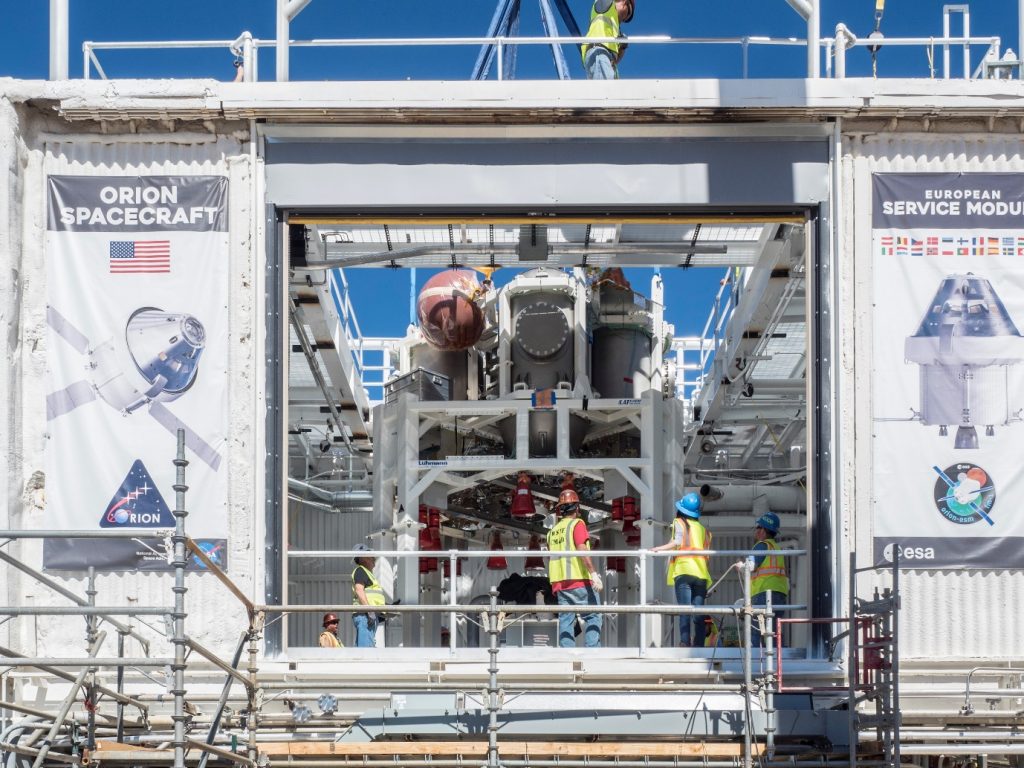

In 2017 the PQM was finished, packed and shipped from the snowy Sweden to the considerably warmer White Sands Test Facility in New Mexico, USA.

Getting hot in White Sands

At NASA’s test facility the Propulsion Qualification Module was used to fire its 21 engines divided into three classes: the primary Orbital Maneuvering System Engine (OMS-E) taken from NASA’s Space Shuttle, 8 auxiliary thrusters, and 12 reaction control system (RCS) thrusters.

As the primary engine, the Orbital Maneuvering System Engine (OMS-E) is a liquid propellant rocket engine that will provide the thrust needed to perform the major manoeuvres during the Orion mission.

The 8 auxiliary thrusters provide thrust for medium and large manoeuvres (such as orbit corrections) and serve as a backup to the OMS-E.

RCS thrusters allow the spacecraft manoeuvring and attitude control. They enable small bursts of thrust in any direction and are key to manoeuvring during orbits and reentry, docking, and control orientation.

The actual European Service Module has a total of 33 engines, including the OMS-E and 8 auxiliary thrusters, but 24 rather than 12 RCS thrusters compared to PQM. The extra set of RCS thrusters were left out of the Propulsion Qualification Model, as they are not required to verify the overall propulsion system and are therefore redundant.

The fiery continuation of the PQM story happened in 2017 with the first testing whereby the engines were ignited and fired for varying lengths of time to test all scenarios. This test campaign involved teams from Airbus, ESA, NASA (Glenn Research Center, White Sands Test Facility) and Lockheed Martin.

A trusty test workhorse

The PQM was used until end of 2020 to support the qualification of the Orion’s propulsion system of the European Service Module. The final hot firing took place in early 2020.

The PQM was formally handed over to NASA as it has completed its primary goal to qualify Orion’s propulsion for flight. The model will stay at White Sands however to support the preparation and operations of the Artemis I mission.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

NASA Orion page

NASA Orion page NASA Artemis

NASA Artemis Airbus Orion page

Airbus Orion page

Discussion: no comments