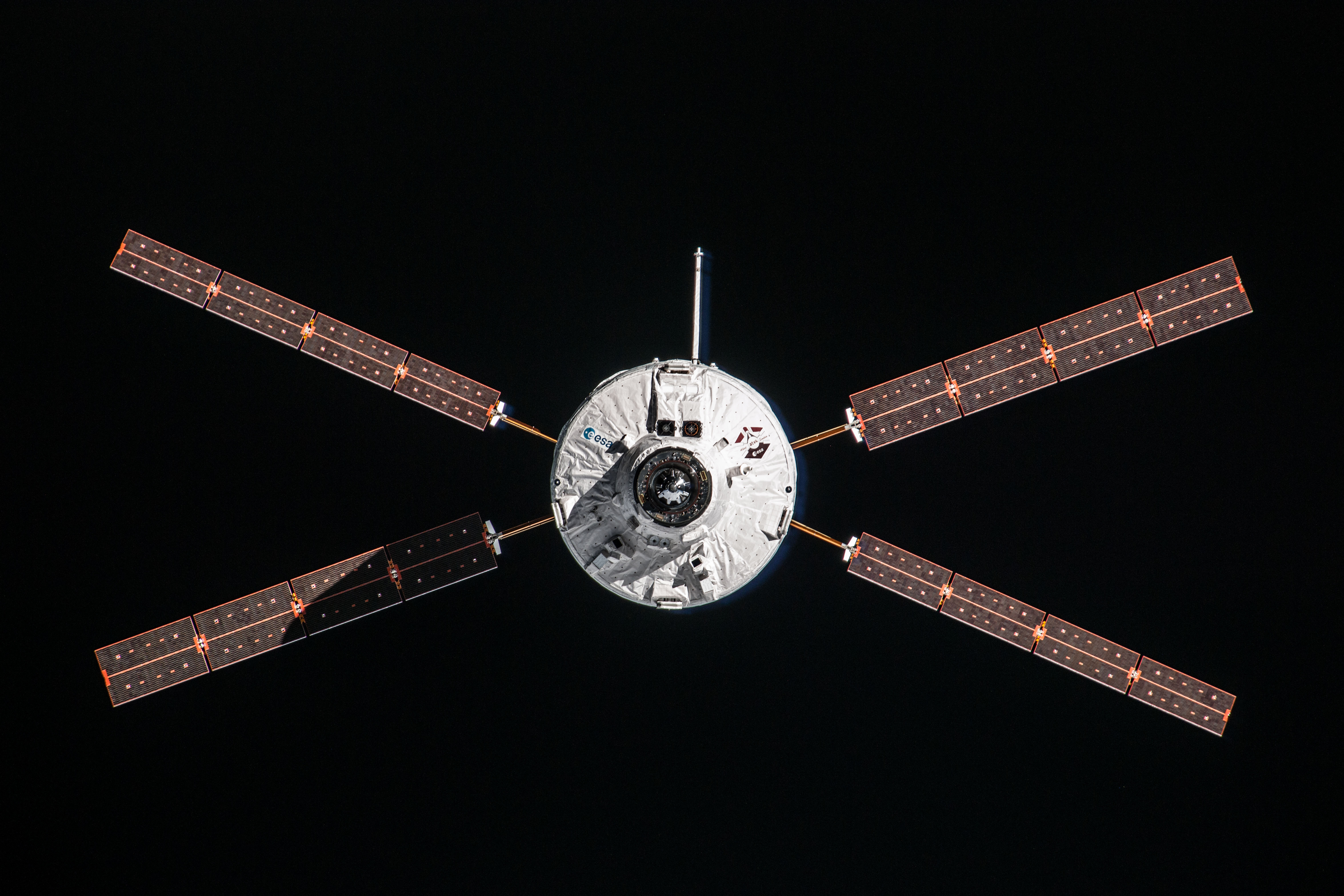

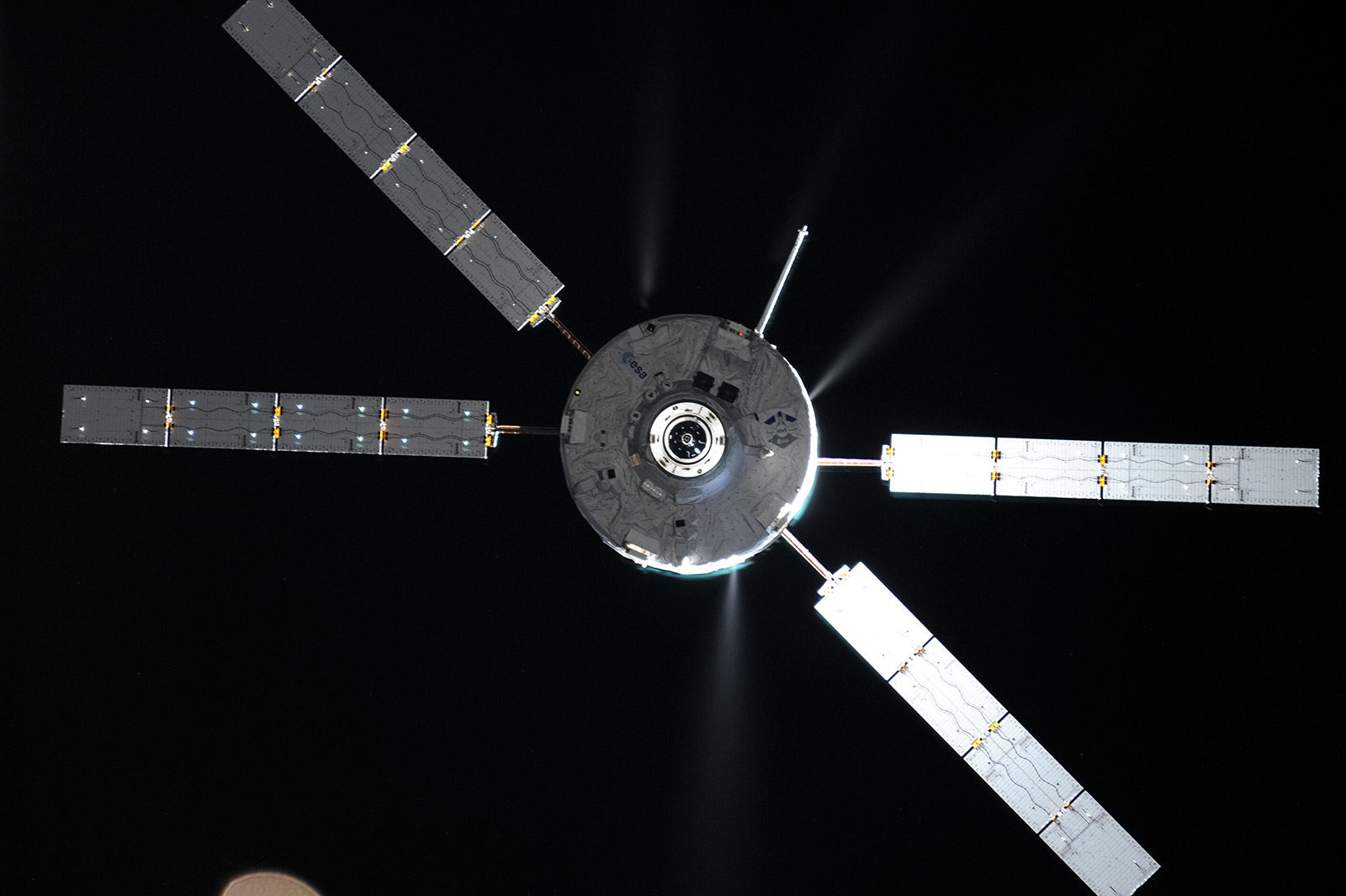

Quick overview: ATV-4 cargo for the International Space Station

- Fuel for the Russian engines: 860 kg (loading 2 & 11 April)

- (Russian) Water for the Crew: 570 kg loaded

- Air and O2: 66kg & 33kg, respectively (loading 13 & 15 April)

- Fuel for boosting ISS orbit: 2235kg (loading 19/20 & 25/26 April)

- Dry cargo: 2501kg (partly complete; late load cargo loaded in May)

Next milestone: ATV transfer to BAF (Batiment d’Assemblage Finale) at Kourou – May 6

Note: Today’s post provides the latest update from Charlotte Beskow’s mission diary from Kourou, where she is serving as the Launch Campaign Manager – Ed.

Prior to 28 March (i.e. before ATV transfer to S5B)

Fuel loading is a complex operation that needs careful planning. Some tasks are ‘high-tech’ while others are more mundane, although no less important.

Preparing to set up the fluid ground support equipment (FGSE). All the necessary equipment is checked and sorted before Albert leaves S5C. Credit: ESA/C. Beskow

With ATV still in the S5C hall at Kourou, the very first task was to pressurize the He (Helium) system of both the Russian Fuel System (RFS) and the ATV propulsion system (PRSS). This was done already 23 March (RFS compensators), 25-26 March (RFS He loading) and 26 March(PRSS He loading); in other words, we finished before Albert was carted off to S5B.

In parallel, the UDMH fuel was being prepared in S5B for loading. It underwent a process called degassing.

28 March – ATV Albert Einstein transferred S5B

ATV 4, Albert Einstein, was finally transferred through the long corridor to S5B. How many people does it take to move a 12-tonne space vehicle?

Only a few people could watch it ‘in-situ’. The rest of us followed this important event via the video screen in the Safety Room.

As soon as Albert had entered the corridor, we all crowded into the Visitor’s Room from where we had an excellent view as it glided down the corridor.

No worries… it will fit! The building was designed with ATV in mind!

As soon as Albert had entered the corridor we all crowded into the visitor’s room from where we had an excellent view as it glided down the corridor. Credit: ESA/C. Beskow

As soon as Albert had entered the corridor we all crowded into the visitor’s room from where we had an excellent view as it glided down the corridor. Credit: ESA/C. Beskow

If all goes according to plan, then Albert will not come back to S5C; teams can start to pack up. Some equipment goes back to Europe and other items go into temporary storage here at CSG… waiting for the last of the vessels to arrive (that would be ATV-5 later this year).

29 March – Propellant loading

Friday: The work to prepare for propellant loading has been going on for quite some time, so as soon as Albert is secure on the stand in S5B the teams ‘roll up their sleeves’ (read: ‘get into their clean room clothes’) and get going. We are loading four types of propellant and two types of gas, so there are a number of activities to be carried out, many of them rated as hazardous.

2 April – Loading UDMH

After a short break for Easter, it was time to load the UDMH, one of the components of the Russian fuel (N2O4 Nitrogen Tetroxide is the other – Ed.).

After a few hiccoughs in the morning, loading got under way and we could follow it from our offices via the monitors. I did not take a picture, so here is a picture from a similar operation during last year’s ATV-3 launch campaign:

That done, it was time to roll out the UDMH equipment in order to allow the MMH-related equipment to be set up in the same area (MMH loading takes place 19-20 April).

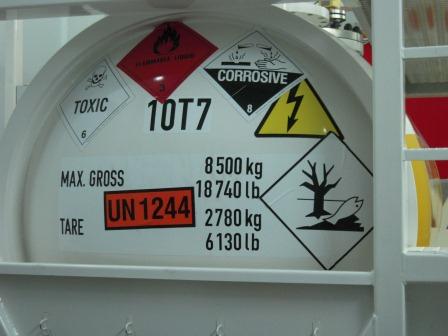

Hard to miss that this is toxic. This applies to each of the four fuel components, which is why the entire transport, handling, loading and cleaning process takes so much time. Credit: ESA/C. Beskow

The big MMH tank (8000 kg capacity) arrived at the airlock in the late afternoon. It’s hard to miss that this is toxic. This applies to each of the four fuel components, which is why the entire transport, handling, loading and cleaning process takes so much time.

3 April – Processing MMH

Wednesday: The MMH tank now stays in the S5B Ergol (‘propellant’) room for a passive phase called ‘conditioning’. This means the temperature goes back down to room temperature, a process that takes several days (right up to MMH loading on 19 April).

4 April – Feeling like a short week!

Thursday: This week feels VERY short. We only just started and it is already Thursday! Time for the next steps: NTO (Nitrogen Tetroxide) sampling on Friday followed by degassing on Saturday; NTO is the oxidiser component of the Russian fuel. It needs to be ‘degassed’, which means stripping away the Ni atoms and replacing them with He ones.

Prior to starting the operation, we had the opportunity to check the set-up (just like we had done for UDMH).

There is a large number of control panels between the fuel tank and the equipment (and between the fuel tank and ATV once we get to that stage).

There are numerous valves to be opened and closed. The fluid lines have metallic labels at each end with a number engraved; the number is found on the set-up diagram and this is what is being checked before starting.

5 April – NTO sampling

NTO sampling takes place; CSG (Centre Spatial Guyanais) will do the analysis and provide the results asap to the propellant loading team. We need to get them before the degassing takes place on Saturday, 6 April.

6 April – NTO degassing

CSG provides the sampling results late Friday and NTO degassing gets under way on Saturday. Another hazardous operation that runs smoothly! The teams are done late in the afternoon, and then the weekend can begin. Outside the sun is shining and it feels like the dry season!

April 8 – Preparing for gas loading

Preparations start for gas loading. ATV will carry 67 kg of air and 33 kg of Oxygen and these two gases will also be loaded in S5B.

As you can see there is quite a lot of equipment to be unpacked and readied for this task. Credit: ESA/C. Beskow

As with fuel loading, this is considered to be a hazardous operation. The reason is the high pressure in the bottles: on the order of 200 bar.

The necessary equipment will be unpacked and prepared in S5C before moving everything along to S5B for the actual loading. First loading is O2 (Oxygen) on Saturday, 12 April.

As you can see there is quite a lot of equipment to be unpacked and readied for this task!

9 April – Leak tests

Leaktightness tests continue for the NTO loading (still scheduled to take place Thursday, 11 April). Preparations for oxygen/air loading also continue (actual loading April 13 and 15) as do the various planning meetings to ensure that all the material is available at the right place, at the right time, and in the correct condition.

Sure, we might be called ‘rocket scientists’, but a good part of our time is spent on careful planning of logistics. A task that can never be overestimated…

Image from the daily morning meeting. Several familiar faces attend, representing ATV history that goes back to 2007! Credit: ESA/C. Beskow

That’s it for now!

– Charlotte

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: 2 comments

Hi,

some questions I have regarding ATV-4:

Why does it take 10 days for ATV to reach the ISS? Has that something to do with the mass of that ATV? In comparason to other ISS Visiting vehicles that’s quite a long time. Soyuz/Progress just need 6 hours. Maybe you could write a blog with more details about orbital mechanics and the approach the ATV uses.

Second: I am curious if you could publish or send me directly a more detailed list of the dry cargo that will fly onbord ATV-4. That would be much appreciated.

Finally I like to thank all of you for your great work on ATV and on this blog. I had the honour to visit Astrium Bremen on the 25th for a Diversity Day Event for an internship there and was able to see the last ATV-5 there. That was awesome! Keep up the great work!

Best regards

Ian Benecken

Hi Ian,

Thanks for your query; full answer from ESA Mission Director J-M Bois here: https://blogs.esa.int/atv/2013/04/12/atv-4-ten-days-launch-to-docking/

The list of ATV-4 dry cargo will be published shortly.

Thank you also for your kind comments!

— Daniel