Accelerating the Transition to Zero Debris Platforms for LEO

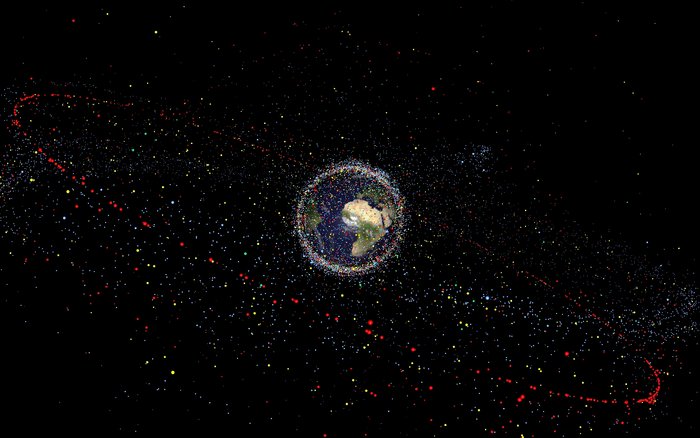

The Low Earth Orbit (LEO) environment is facing unprecedented pressure. In recent years, the utilisation of this orbital zone has grown substantially, leading to a rapid degradation of its condition. To address this challenge, the European Space Agency (ESA) is taking decisive action through its Zero Debris approach, aiming to set a global precedent and lead by example. The goal: achieve full implementation by 2030.

A cornerstone of this approach is the evolution of European satellite platforms, including large LEO systems. These platforms require significant adaptation to comply with the new Space Debris Mitigation requirements, which call for technological advancements across multiple subsystems.

The Zero Debris Large Platform Activity

To support the transition to Zero Debris (ZD)-compliant platforms, ESA launched the Zero Debris Large Platform Activity in June 2024 co-funded by the ESA Space Safety Program and Future Earth Observation Program, in collaboration with the three major European Large System Integrators (LSIs): Airbus Defence and Space, OHB, and Thales Alenia Space.

The objective is clear: mature the design of large LEO platforms up to Preliminary Design Review (PDR) level, enabling their swift integration into future missions. If you are interested in exploring the background of the Zero Debris Large Platform Activity in more detail, including the explanation of the five technical objectives, you can read more in the article Zero Debris Platforms: A Collaborative Journey Toward a Sustainable Space Environment – The Clean Space blog .

Phase 1

Phase 1 of the activity has just concluded, focusing on consolidating requirements and defining the technological roadmap to bring the ZD platform design up to System Requirements Review (SRR) level. As part of this effort, the consortiums worked on the ESA Space Debris Mitigation Requirements (ESSB-ST-U-007 Issue 1), and on newly introduced seed requirements with more stringent thresholds, to start assessing their feasibility. These seed requirements covered key aspects such as break-up probability, passivation reliability, disposal reliability, and casualty risk per re-entry. The proposed values were discussed, and analyses were performed by the different LSIs to determine whether they could realistically be achieved and how the platform design would be impacted. N w thresholds were eventually consolidated. The outcome of this activity will serve as the basis for Phase 2 requirements, and to inform potential future updates to the ESA Space Debris Mitigation Requirements.

In addition to tightening and consolidating requirements, Phase 1 focused on evaluating technologies applicable to the five technical objectives of the Activity. These technologies were assessed based on their integration potential with the already existing platforms for each LSI and the benefits they offer from a Zero Debris perspective. A key priority was understanding system impacts and ensuring that selected technologies could be adopted in recurring missions, thereby reducing redesign efforts and keeping costs at a reasonable level while remaining compliant with new requirements and future Zero Debris objectives. Close collaboration with suppliers played a crucial role in this process. These efforts have led to the initial shaping of a new platform baseline, with each of the three LSIs adopting its own specific approach.

The work in Phase 1 was divided in six main tasks:

- Task 1: ZD platform requirements analysis and consolidation, including the selection of Earth Observation mission study cases.

- Task 2: ZD platform drivers analysis and trade-offs to identify and select the most appropriate design concepts.

- Task 3: Technology suppliers’ consultations. This task kicked off with a workshop held in January 2025, involving technology suppliers and LSIs to initiate discussions and align on technical requirements. The list below reports the suppliers who participated in the January 2025 workshop. Please note that their participation does not imply selection for technology development in Phase 2, nor does it exclude the involvement of additional suppliers in Phase 2.Aero Sekur SpA, Aphelion Industries Limited, Arkadia Space, Ascend Beyond Space, DLR, Haydale Composite Solutions Ltd, INVENT GmbH, Lukasiewicz Research Network – Institute of Aviation, Astroscale, Peak Technology GmbH, Plextek Services Limited, Rockwell Collins Deutschland GmbH, Sensmetry, TWI Ltd.

- Task 4: Definition of the ZD platform up to SRR level, including baseline and design options. This task also included a preliminary definition of the platform adaptation plan, identifying recurrent and non-recurrent activities required to tailor the generic platform to specific missions.

- Task 5: Definition of a ZD platform evolution roadmap for future work, including the identification of required technology developments.

- Task 6: Study synthesis and formulation of recommendations.

Work performed and approaches adopted

The following summaries are organised by technical objective (TOBJ):

TOBJ1 – Fully demisable platform

Re-entry assessments were performed to identify the most critical platform elements. Based on the results, several components were selected for further Design For Demise (D4D) development to improve demisability, including reaction wheels, tanks, and magnetic torquers (MTQs). Early fragmentation principles were also analyzed, and demisable structures (e.g. joints) were retained for missions performing uncontrolled reentry.

Technologies identified and pre-selected in Phase 1: Demisable Reaction wheels, Demisable (and detumbling) Magnetic Torquer, Demisable Metallic tank, Demisable Composite Overwrapped Pressure Vessel Tank, Demisable High Pressure composite tank, Demisable Solar Array Drive Mechanism, Demisable joints, Demisable Reaction Wheel bracket, Demisable Cylinder, Demisable Hall Effect Thruster, Demisable Star Trackers.

TOBJ2 – Modular implementation of controlled re-entry

A decision tree for controlled re-entry was proposed to support future implementation, providing a means to anticipate required changes in cases where a controlled re-entry, not initially foreseen, becomes necessary. This approach aims to minimise impacts on mission design and enable a robust platform definition as early as possible in the development phase. Two main options for modular integration were considered: extending the baseline propulsion system (e.g. with scalable or modular propulsion module) or introducing a solid rocket motor (SRM) and thrust vector control (TVC) deorbit kit to provide the extra DeltaV required.

Technologies identified and pre-selected in Phase 1: Solid Rocket Motor + Thrust Vector Control, Chemical propulsion – scalable tanks, Chemical propulsion – (re-) pressurisation.

TOBJ3 – System resilience

Solutions to strengthen platform resilience were explored, focusing on Fault Detection, Isolation, and Recovery (FDIR) and enhanced health monitoring. Discussions included the potential use of advanced sensors for environmental characterization and health monitoring, of on-board AI for predictive diagnostics, or of enhanced exploitation of telemetries. Other ideas addressed enhanced ground processing of existing data and the integration of monitoring systems to detect anomalies, such as those caused by micrometeoroid and orbital debris (MMOD) impacts.

Platform robustness to MMOD impacts was addressed by performing vulnerability assessments and exploring potential shielding solutions. Nonetheless, gaps in the understanding of fragmentation behaviour, as well as limitations in current tools and methodologies, still hinder the ability to implement design modifications at this time.

Technologies identified and pre-selected in Phase 1: Structural piezo sensors, Health monitoring sensors, Monitoring cameras, AI Failure Prediction, Anti spall meta material, Shielding.

TOBJ4 – Mitigatory operations and design

In case of failure, alternative deorbiting systems for uncontrolled re-entry scenarios were investigated, including drag sails, solid rocket motors with thrust vector control (SRM + TVC), and tethers. In addition, dedicated passivation solutions were considered, such as solar array shunting or battery passivators for electrical passivation, and Shape Memory Alloy (SMA) valves or micro-perforators for fluidic passivation. The possibility of introducing a new autonomous end-of-life mode was also explored, aiming to ensure safe and effective end-of-life management even in the presence of limited operational hardware and potential loss of ground contact.

Technologies identified and pre-selected in Phase 1: New autonomous end of life mode, Drag sail, Electrodynamic tether, Passivation watch-dog, Solar Array Shunting, Battery passivator, Microperforator, Shape Memory Alloy Valve.

TOBJ5 – Preparation for removal

Standard ESA Design for Removal (D4R) solutions remain the baseline to prepare the satellite for removal at the end of life, including MICE, 2D/3D markers, laser retro-reflectors (LRRs), and magnetic torquer short-circuiting. In addition, failure cases leading to a cooperative removal mode were identified, together with the associated CONOPS, and cooperative removal system modes were proposed for selected study cases.

Technologies identified and pre-selected in Phase 1: MICE interface, Detumbling (and demisable), Detumbler, Markers 2D + 3D, Laser retro-reflectors.

Looking ahead to Phase 2

Phase 2, starting Q3 2026, will focus on maturing critical technologies with suppliers and refining the ZD platform design up to PDR level. Zero Debris suppliers will be involved from the very start of Phase 2, with contracts in place with each LSIs. This will help solidify the assumptions and timelines indicated by the suppliers for their technology developments, and this will ensure a smooth integration of the technologies in the platforms.

Related Content

- Follow ESA Clean Space on LinkedIn

- Read more about the Zero debris platform activity on this blog: Zero Debris Platforms: A Collaborative Journey Toward a Sustainable Space Environment

- Explore the ESA Space Debris Mitigation Requirements: ESSB-ST-U-007

- Learn more about the ESA’s Zero Debris initiative

Discussion: no comments