The complete demise of a magnetorquer has been obtained at high heat flux level during a test in German plasma wind tunnel facilities. Why is that interesting?

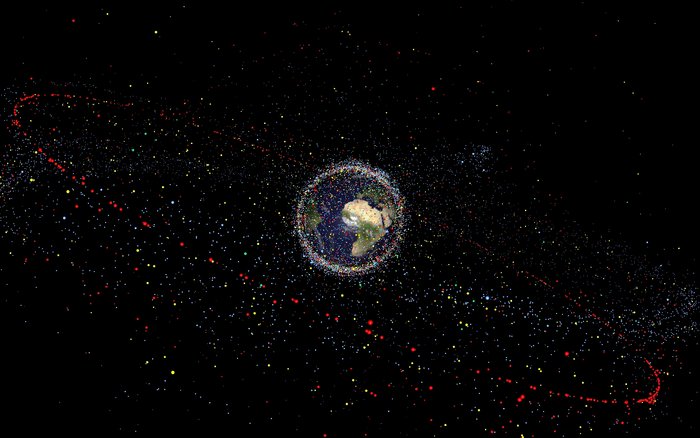

Several activities and simulations have highlighted a number of critical spacecraft elements that tend to at least partially survive re-entry conditions and pose risks on the ground.

Typical examples of equipment surviving reentry are:

- reaction wheels

- propellant and pressuring tanks

- magnetorquers

- SADM (solar array drive mechanism)

- optical instruments.

Major uncertainties in the demise process are the fragmentation events that happen at both system and equipment level during the re-entry. This fragmentation process can drive the casualty risk estimation.

According to simulations, parts may result in a single fragment reaching the ground. But the reality might be different: pieces which in simulation should result in a single fragment, may actually generate several smaller pieces of debris. Basically put, the more pieces you have, the highest the overall casualty risk estimation will be.

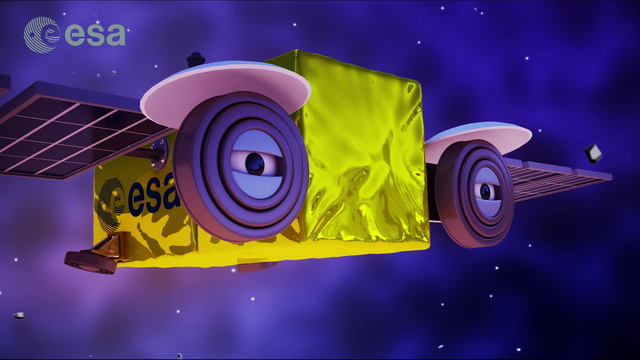

To help fill knowledge gaps in the re-entry arena, ESA’s Clean Space initiative has launched a new activity with Belstead Research and the German Aerospace Center DLR under the name of ‘Characterisation of behaviour of critical elements in re-entry conditions’.

The objective of this activity is:

to characterise the break-up process of critical spacecraft elements through destructive on-ground re-entry tests to be performed in a plasma wind tunnel*.

*Note: Plasma Wind Tunnels (PWT) are used to reproduce the plasma environment during a satellite’s reentry. In previous activities, PWT helped to characterize the behaviour of materials and of simplified satellite structure samples with equivalent conditions to space.

This work foresees the identification of critical spacecraft elements and the on-ground re-entry experiments through test reconstruction in re-entry simulation tools.

This activity is conducted in the frame of Design for Demise, an attractive solution to reduce the on-ground casualty risk resulting from the uncontrolled reentry of a spacecraft.

Design for Demise refers to the intentional design of space system hardware so that it will burn up – or ‘ablate’ – during an atmospheric re-entry in order to reduce the number of surviving parts that reach the ground and the associated casualty risk.

The test results analysis of this activity will help to derive recommendations to apply Design for Demise.

Complex pieces of equipment are going to be tested in the Plasma Wind Tunnel facilities:

- to understand the break-up phenomena of this equipment,

- to improve the risk estimation,

- to implement effective D4D measures.

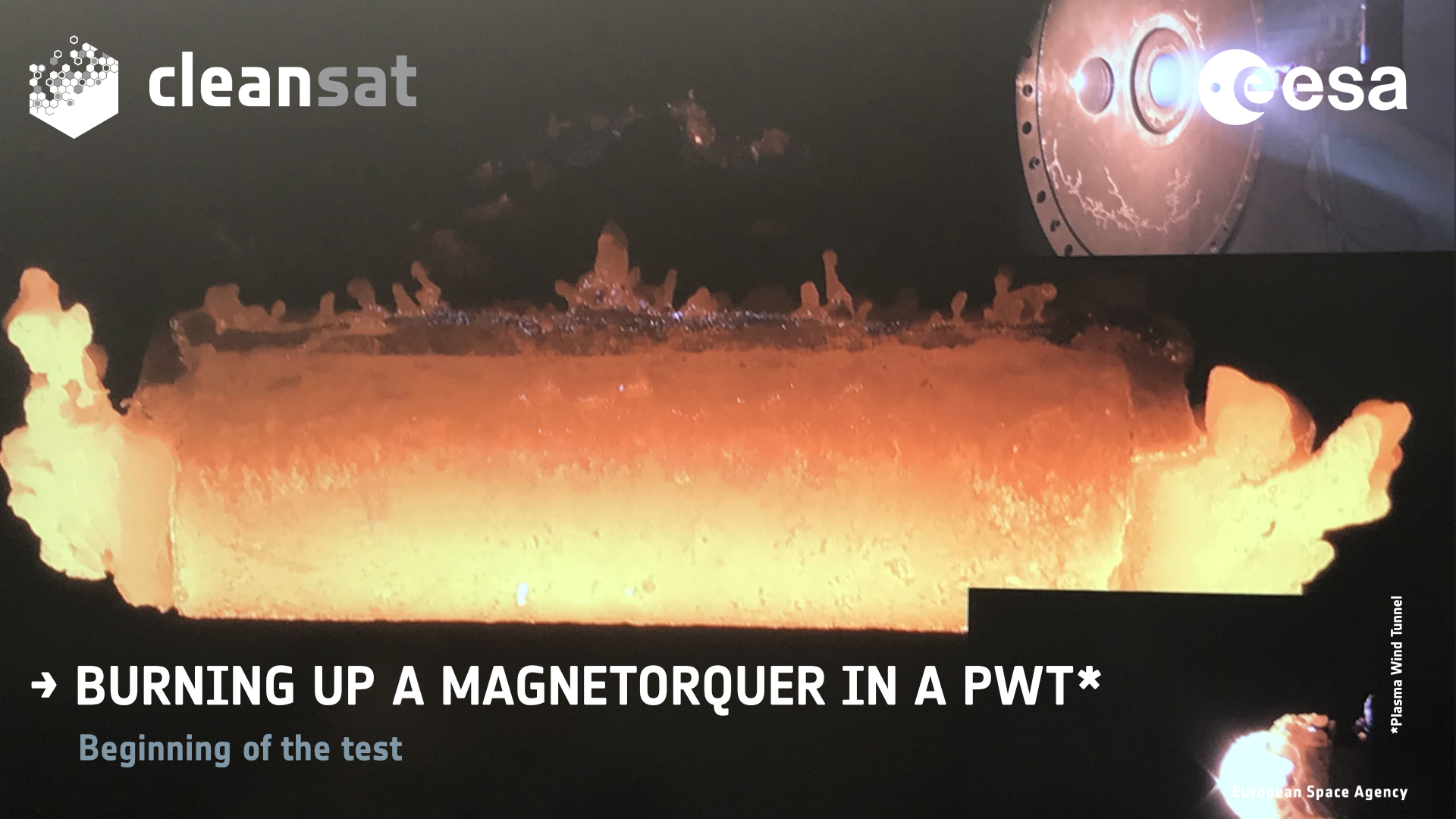

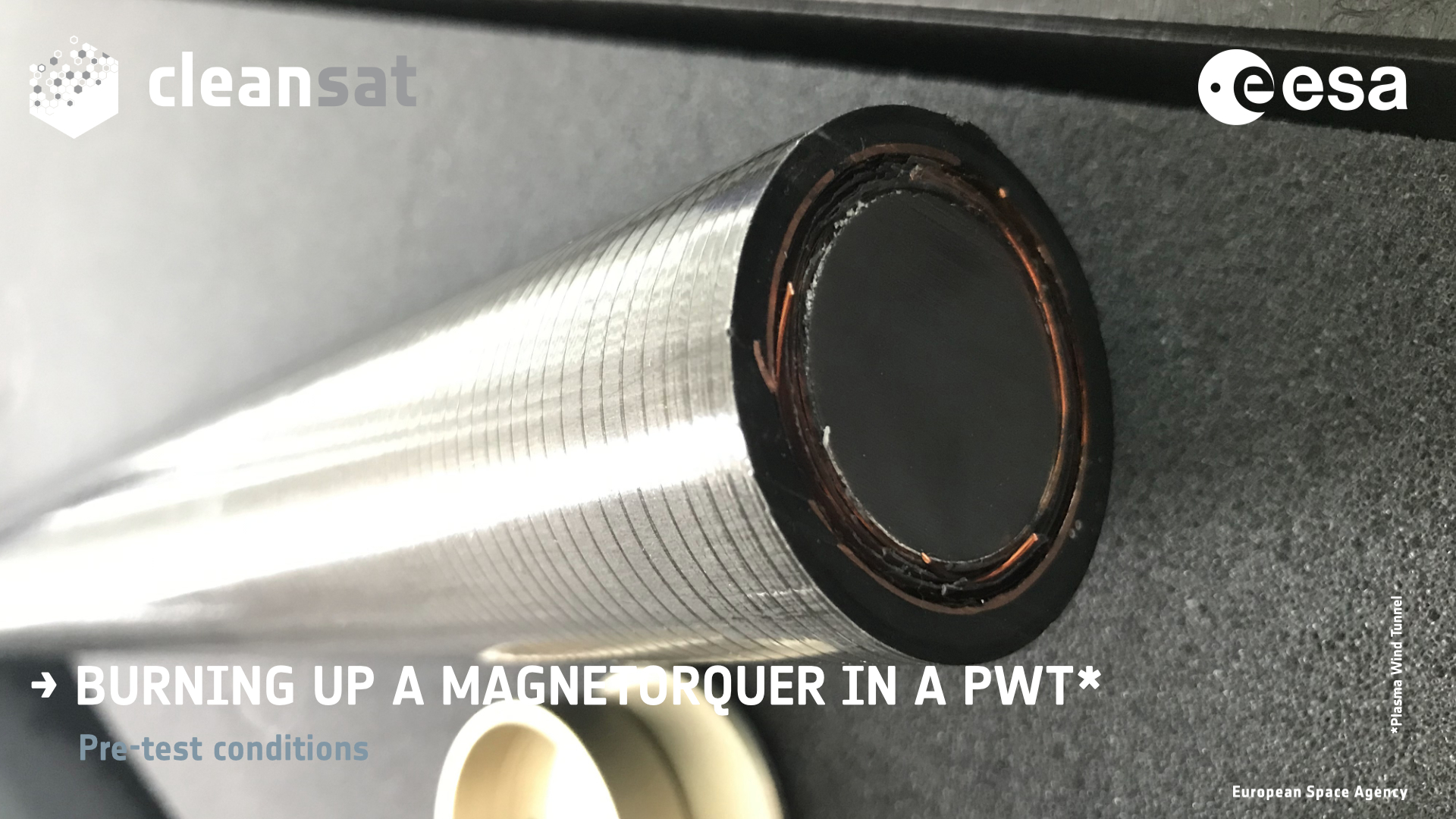

The first tests on the magnetorquers took place at the end of March. Two different samples have been used to demonstrate the capability of demise and fragmentation of the different layer materials.

The Portuguese company LusoSpace provided one of the magnetorquers. It was made of an external layer of CFRP (carbon fibre reinforced polymer), plotting materials, copper coils and an internal core of iron-cobalt.

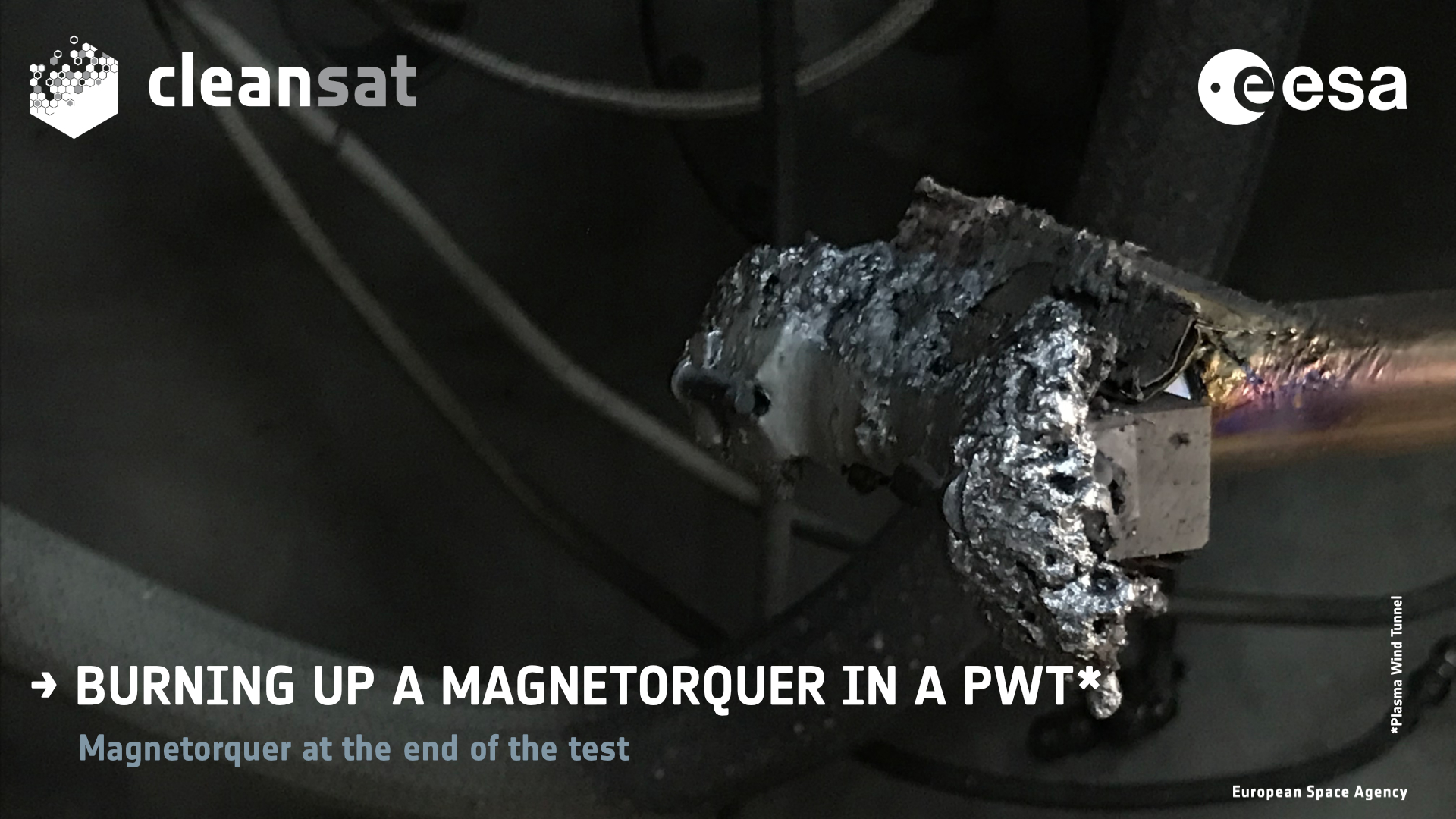

Tiago Soares, Clean Space system engineer, explains: “We observed the behavior of the equipment at different heat flux set-up for the plasma wind tunnel in order to derive more information about materials properties and demisability. The magnetorquer reached a complete demise at high heat flux level!

“We have noted some similarities but also some discrepancies with the prediction models.”

The team will now analyse the test data to get a better understanding of the destructive process of the magnetorquers. “We want to improve the prediction models and propose robust ‘design for demise’ recommendations,” adds Tiago Soares.

The test campaign has only started with magnetorquers. Tests of other spacecraft equipment will take place end of May. Stay tuned! We’ll keep sharing the latest information about this activity on the blog, and we will post more pictures on our Twitter account.

Related posts:

Discussion: no comments