A lot is done in the space industry to gather knowledge about our changing planet. Many programmes, such as Europe’s Sentinel series of Earth Observation satellites, are providing data to guide policy makers now and in the years to come.

But how much are we ourselves impacting the Earth environment with such activities? How can we redesign satellites to be more environmental friendly in their production, operation and disposal? In recent years ESA has been applying Life Cycle Assessments to space missions to answer these and related questions, but how does it really work?

Being the best

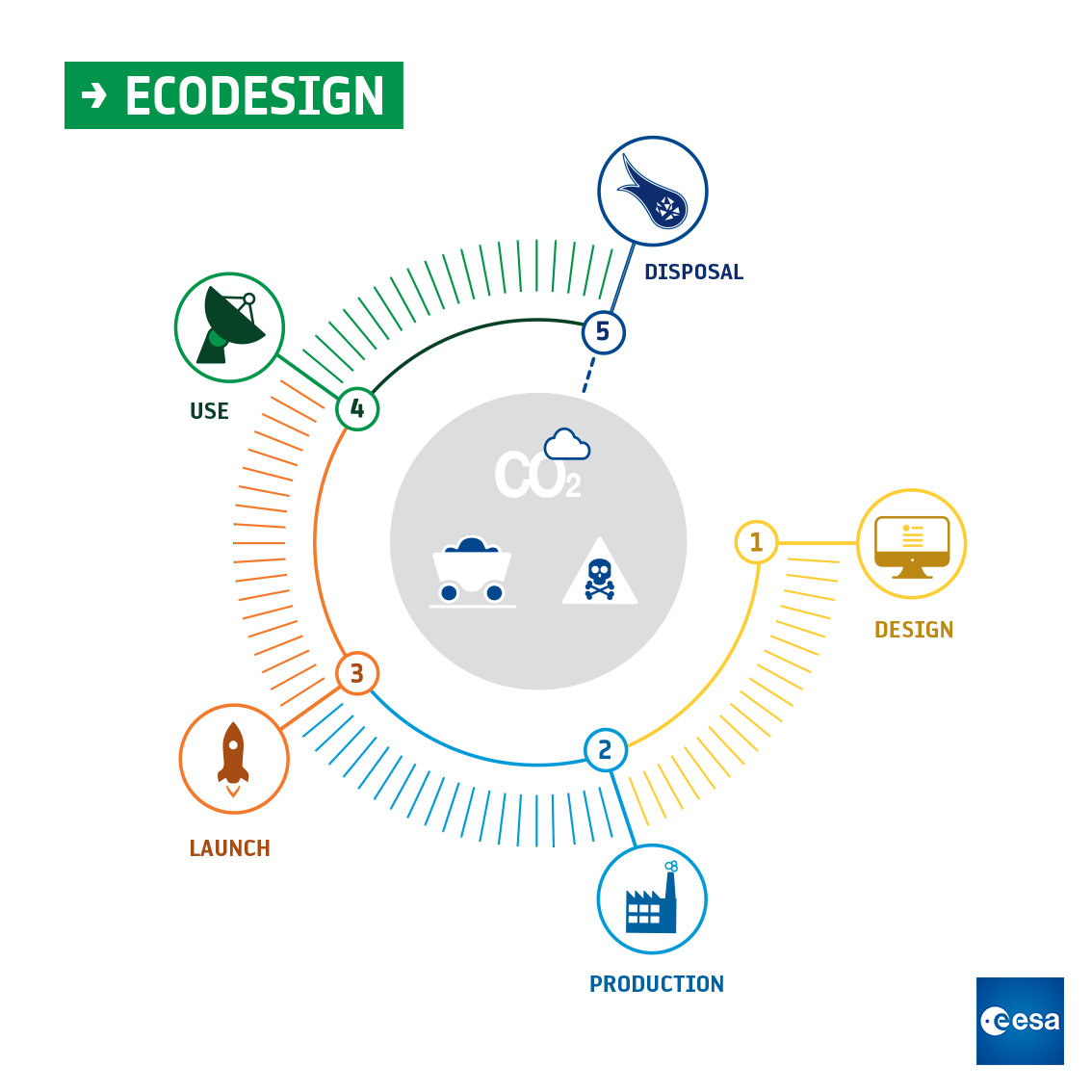

The main goal of ESA’s EcoDesign activities is to quantify the environmental impacts of space missions and identify solutions to reduce them. Life Cycle Assessment (LCA) is a standardised tool we apply in measuring this impact. LCA considers all activities of a mission from cradle to grave, thus avoiding burden shifting by improving one aspects and worsen another. LCA also clarifies total material/energy use and emissions of the activities in question, and can simplify complying with regulations such as REACH. These advantages come, of course, in addition to the fact that taking steps to decrease environmental impact is the moral thing to do.

How a life cycle assessment works

The current LCA frameworks, as set by the European Commission and by the International Organisation for Standardisation, do not make special considerations for the space industry. Space is, after all, a relatively small part of world economic activity. However, the extreme environments that satellites and launchers have to endure, forces us to make considerations not necessarily applicable to other industries.

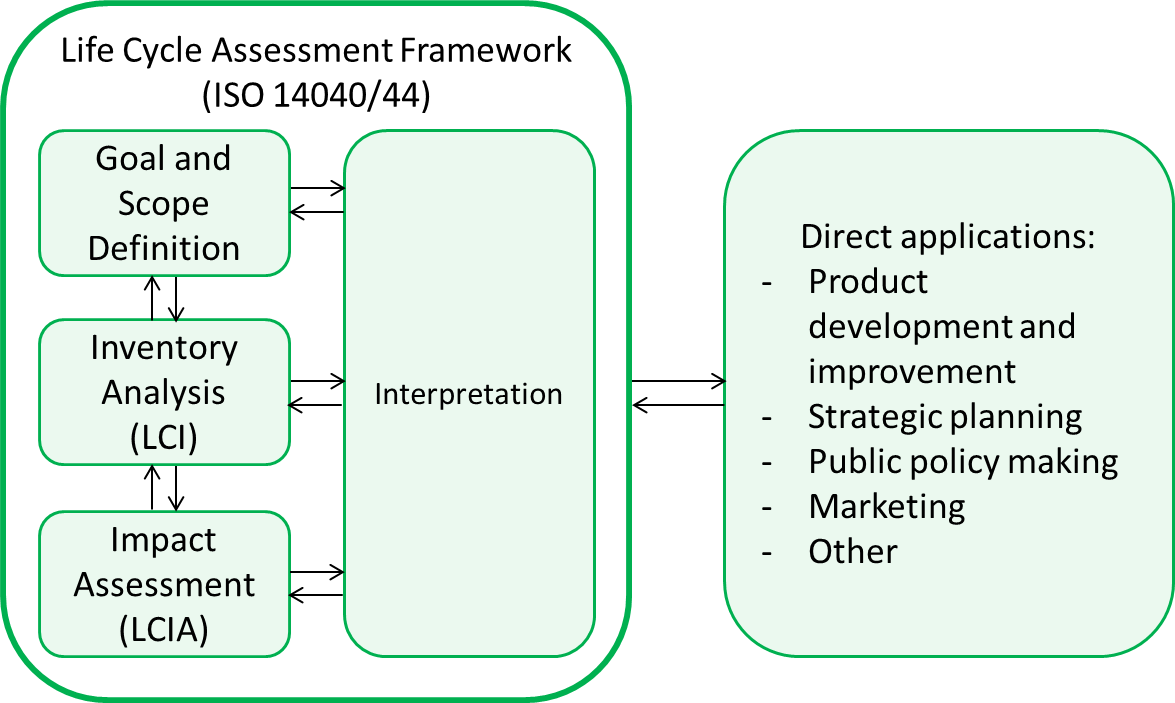

In general terms, an LCA consists of 4 steps:

- Goal and scope definition,

- Life Cycle Inventory (LCI) analysis,

- Life Cycle Impact Assessment (LCIA), and

- interpretation of results

The goal and scope state the intended application of the study, define the LCIA method, the boundaries, and define the study’s functional unit, i.e. a quantified description of requirements that the studied product must fulfil.

The LCI analysis consist of collecting, calculating and allocating data on use of energy and materials in production and processing, as well as accompanying co-products, waste, and release to air, water and soil. A widely used example is the database ecoinvent. In this vein, ESA is developing a space specific database for European stakeholders.

The LCIA defines the impact categories to assess, e.g. global warming, human toxicity and mineral depletion. Several sets of LCIA methods are in use.

The interpretation of results comprises identification of significant issues, hotspots, sensitivity analysis, limitations and recommendations.

Through this multi-step, multi-criteria methodology, we avoid burden shifting, as the impact of the mission is seen as a whole, and enables us to take well-informed decisions on where to invest in improving technologies and processes.

LIFE CYCLE ASSESSMENT FOR SPACE

When it comes to applying the LCA to space, there are many special factors to consider.

EcoDesigning a space mission

Credits: ESA

Many materials and processes are specific for space activities or not commonly used in other industries, e.g. germanium for solar arrays, or exhaustive surface treatment to guarantee endurance in space, and therefore the available LCI databases are not sufficient.

Space missions also have long production cycles and low production volumes. Due to the testing and operations there is an extensive use of specialised, energy demanding facilities such as clean rooms and ground stations.

Launches have been shown to have a negligible effect on the environment, compared to the planning, production, qualification and operation of launchers and satellites. The exception comes with the depletion of the ozone layer, which the launcher has a serious impact on, with direct emissions in the high atmosphere. On the other hand, we know little about the impact on the atmosphere by the demise of spacecraft upon re-entry, and the deep sea impact of launchers that come down in the ocean.

ESA is currently investigating all of these issues.

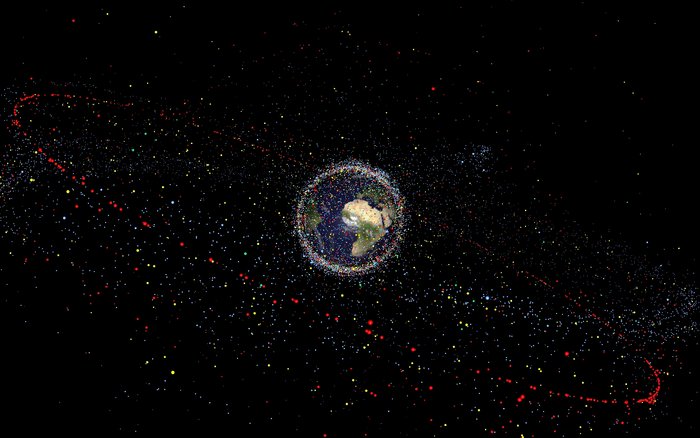

The threat of space debris is also growing, and here ESA is leading the world with projects to decrease and deorbit debris. Work has been initiated to develop a space debris indicator, to apply to LCA as an LCIA impact category, to compare various space missions’ contribution to increased space debris.

ESA now offers a training course on LCA for space to its staff, and is offering this training to European industry for the first time in 2018. In the past we have performed LCA studies with industry on a selection of ESA missions, and we have developed a handbook on LCA for space.

There is also a tendency to apply LCA more widely across the space industry. E.g., it is a requirement in the initial statement of work of the Ariane 6 to perform an LCA. ESA’s Clean Space office has presented the current work on LCA in space in technical universities all over Europe, and we will continue to do so.

Discussion: one comment

Hi,

This is a interesting topic. I want to make college project on removal of space debris. Can you help me in this regard i.e. ideas?

Your suggestions will be highly appreciable.