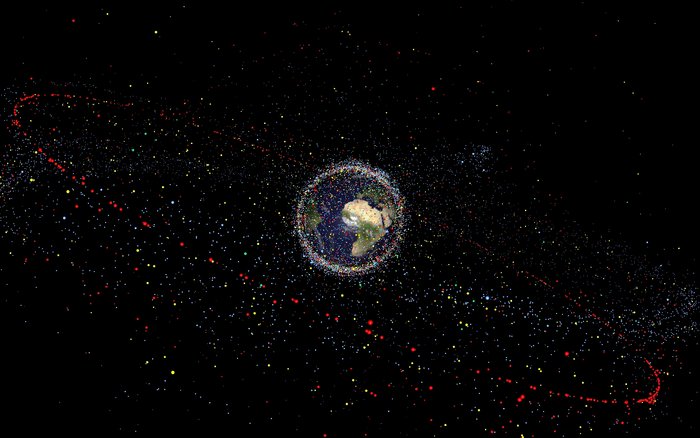

From the beginning of the Space Age to our days, about 700000 objects larger than 1 cm have accumulated in orbit, counting both currently operational satellites and space debris. If you consider that the force of a 1 cm object strike on a satellite is about the same as an exploding hand grenade, then I’m sure you will agree how important it is to ensure that we do not add further debris in orbit.

While in orbit collisions are a major source of debris, explosions or breakups coming from the spacecraft equipment itself also pose a big risk. Hence, there is a need for spacecraft passivation, meaning the removal or deactivation of all potential sources of explosions.

We have previously covered the explosive potential of the electrical subsystem in this blog, including where it comes from, the need to address it, and how we at CleanSat are looking into ways of solving the problem. This new post addresses passivation of the propulsion subsystem.

Credit: Marianne Tricot (Ecole Estienne Paris) – ESA

Once a spacecraft is deactivated, it can drift into orbital and attitude states that it was not designed to cope with, which can significantly raise the satellite’s temperature. This in addition to the fact that thermal subsystems are off and MLI (Multi-layer insulation) may no longer be effective. When tanks suffer a temperature increase due to sustained sun-pointing, the propellants may begin dissociating, which in turn can lead to a pressure increase in the tank. This is particularly problematic in the case of hydrazine, where the dissociating process is exothermic and further increases the temperature inside the tank, acting in a positive feedback loop to speed up the pressure increase process. If the added pressure has no way to vent, it will continue to build up until the tank breaks. Even if the pressure does not build up to breaking point, it will nevertheless increase the chance of tank explosion in case existing debris hits it in a hypervelocity impact. As you can no doubt imagine, when either type of explosion happens a large amount of debris will be created. In order to avoid this, we must ensure a complete satellite passivation while the spacecraft is still under control, including venting any leftover propellants.

Unfortunately, expending the excess propellant via the thrusters cannot currently be done in a controlled way after tank pressure drops below 5 bar or so. This triggers the need for special purpose valves that allow for the complete venting of the propellants (or pressurant in some cases).

These valves are termed passivation valves, and are normally-closed valves. This means that they are not used during the lifetime functioning of the propulsion subsystem, but are instead only triggered at the end of life of the satellite. When triggered, these valves open to the vacuum of space, the pressure difference between the tank and the vacuum does the rest and the stored propellant is vented safely to space.

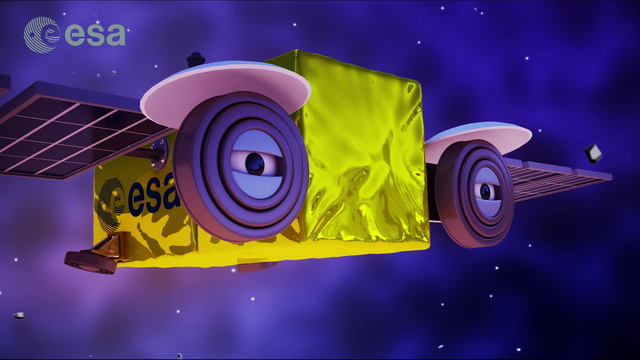

SMA valve EM

Credit: Airbus Safran Launchers GmbH

Pyrovalves are already in general used as normally-closed valves, their use for this End of Life is not possible as they are currently only qualified for a maximum of 8 years in space, and such passivation procedures are usually carried out 10 – 15 years after launch.

Fortunately, the developments in material science of the last few decades have produced a novel solution: Shape Memory Alloys (SMA). These are special metal alloys that can be cast in a certain shape, deformed into a different one and maintain this state until they are triggered to return to the original shape through heating.

For the passivation application, the SMA is initially compressed such that the valve is closed. Then, at spacecraft End of Life, heating is applied to trigger the actuator’s ‘memory’ and return it to its original shape, breaking a notch and thus opening the valve and allowing the propellant to flow out of the tank. The change of the material phase means that, once opened, the SMA valve stays open.

This new technology bring the advantage of having no lifetime restrictions, a simple design and low cost.

At CleanSat, we have started to study the use of these SMA passivation valves, via on-going studies at the Concurrent Design Facility of ESTEC with the participation of suppliers, large spacecraft integrators and ESA experts on propulsion and material science. The next stage is to qualify the technology for use on future satellites. However, as passivation occurs at the end of mission, we may have to wait years before the first SMA passivation valve is activated in space!

Discussion: no comments