The European environmental regulation REACH has considerable implications for European industrial activities. But space, as a strategic asset of fundamental importance for the independence, security and prosperity of Europe and due to its nature and high technological demand, is in need of special materials. How does the sector handle the situation?

This post is composed of two parts. The first one is a brief introduction about REACH: what is it and how does it work. If you already know what REACH is, you may skip it and go directly to the second part which focuses on the implications for the European space actors.

1.Basics about REACH

To ensure that materials or chemicals used in production, manufacturing or end-uses are not hazardous for humans or the environment, the European Commission issued the REACH regulation: Registration, Evaluation, Authorisation and Restriction of Chemical Substances. This environmental regulation applies to all sectors producing or using chemical substances, including the space sector.

Environmental legislations and regulations can be an effective tool to improve our life here on Earth as the Montreal protocol strikingly demonstrated. The protocol limited the use and production of CFCs (chlorofluorocarbure, an organic compound contributing to the ozone depletion) in the 90s which is resulting in the recovery of the ozone layer.

REACH requires all chemical substances produced or used by industry to be registered with the European Chemicals Agency (ECHA). Based on these inputs and their research, ECHA assesses if any of the registered substances may constitute a risk to human health or the environment. Through a subsequent evaluation process a substance may be placed on the candidate list of ‘Substances of Very High Concern’ (SVHC) by the European Commission (EC). This results already in legal obligations such as the provision of information for safe use and handling if a substances is present in articles above 0.1% (w/w).

ECHA is regularly assessing the candidate list and proposes a subset of substances that should be further prioritized for inclusion in the authorization list (Annex XIV). These substances undergo another evaluation process leading to EC decision for Annex XIV inclusion. At this stage substances have already been assigned a ‘sunset date’, after which their use must be phased out.

To use a substance beyond this date, companies need to apply for authorization to continue using it in their particular industrial fields. For this, they have to provide proves based on socioeconomic analysis, process control details as well as current state-of-the-art for potential replacements. Generally this means that the overall risk posed by stopping its use has to be shown to be greater than the risk of continuing to use it. It is however a resource intensive process and authorization is only granted up to a defined revision period. This creates a driving force that companies will prefer to replace hazardous substances whenever technically and economically viable.

2.Implications for European space activities

The amounts of materials we use for space activities are usually very small and/or very specific, so why should they be of very high concern?

While this is partially true, this is also part of the reason why the space sector is so affected by REACH. Several industrial sectors already had to start changing their products, especially if they rely heavily on the use of chemical substances. The cosmetics industry, for example, had to start the registration and evaluation process very early and several substances will have to be replaced in the coming years. Since the space sector is small compared to other sectors, most materials are not produced primarily for space, especially not upstream, at the beginning of the supply chain. If now a supplier can satisfy his major customers with a new solution, the original product may not be available anymore for a remaining niche sector.

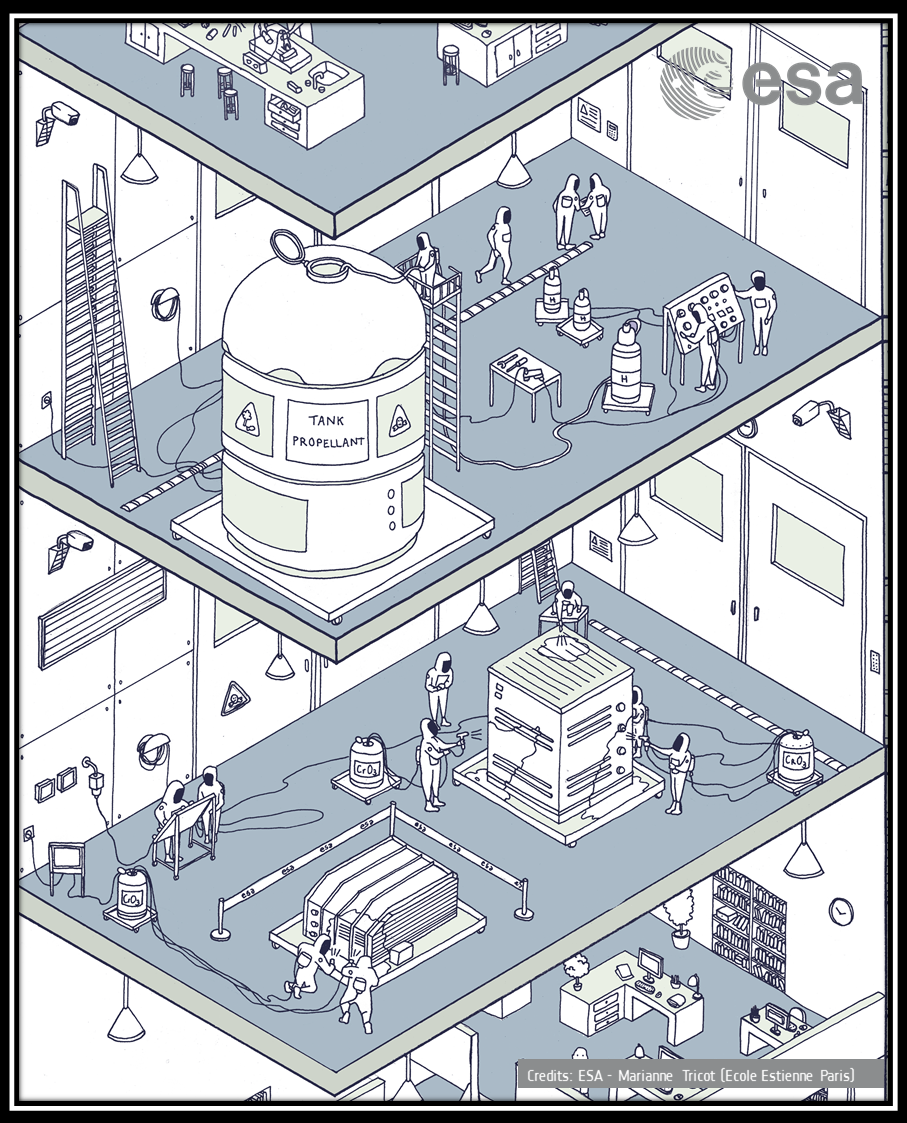

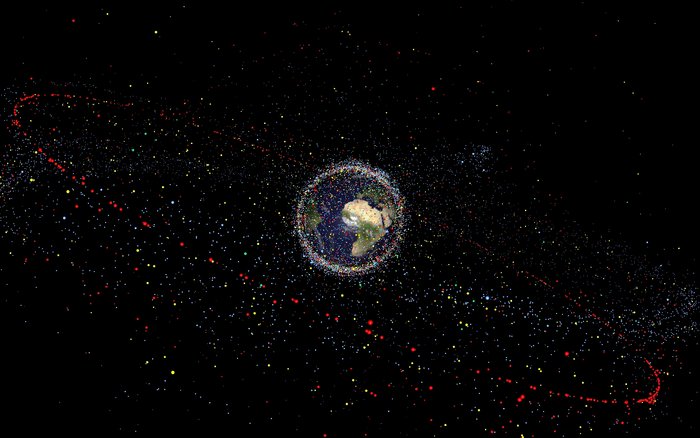

Space technologies are very demanding in terms of performances. For example, they have to fly though impressively difficult environmental conditions such as high vacuum, radiation, and temperatures ranging from approximately -120°C to 120°C in the low-earth orbit. This requires very specific technologies and high performance materials. This also means that existing alternatives for Earth applications might not fit to space-specific applications. An example of an Annex XIV substance is chromium trioxide used for corrosion protection of aluminum alloys. So far no alternative system provides the same level of performance, a major challenge not only for space but also for aviation industry. Specific challenges for space industry become also obvious for hydrazine that is now on the candidate list of substance to be regulated by REACH.

So to avoid a disruption in the space sector supply chain by materials and components being simply not available any more, there is an urgency to start developing alternatives and to qualify them. But this is costly. Indeed, any new changes in a technology must be requalified before it is allowed to fly it, including possible design modifications.

To proactively meet these wide and varied changes on European level, ESA, national space agencies and the space industry are together engaged in the so-called Materials and Processes Technology Board to manage the risk of ‘obsolescence’. This includes the establishment of a long-term risk assessment for space specific materials and processes, and formulation of joint actions to avoid future supply chain disruptions. The latter may include the formulation of R&D proposals for substance replacement or efforts towards REACH authorization where no replacement is yet feasible. Finding surprises late in a project, when a component or a process is not available anymore, would lead to costly mitigation actions. The analysis shows that about 4% of industrial materials used in the space industry are impacted by REACH in the short term. And this figure is likely to double in the mid-term and could reach up to 20% in the long term.

The European space sector is working closely together to manage the consequences of the REACH regulation with dedicated activities for finding replacements of affected materials and substances. ESA, through Clean Space, also develops methods and tools to pro-actively address these topics in an early stage of a space mission life-cycle to mitigate supply chain disruption risks.

Discussion: no comments