- Ingredients:

- 1 space-grade silicone polymer

- 1 meteorite

Finished result

- Tools:

- Spatula

- Brush

- Rotary grinder

- Vacuum oven

- Preheat settings:

- Vacuum oven to 100°C at 0.01 mbar

- Oven to 400°C

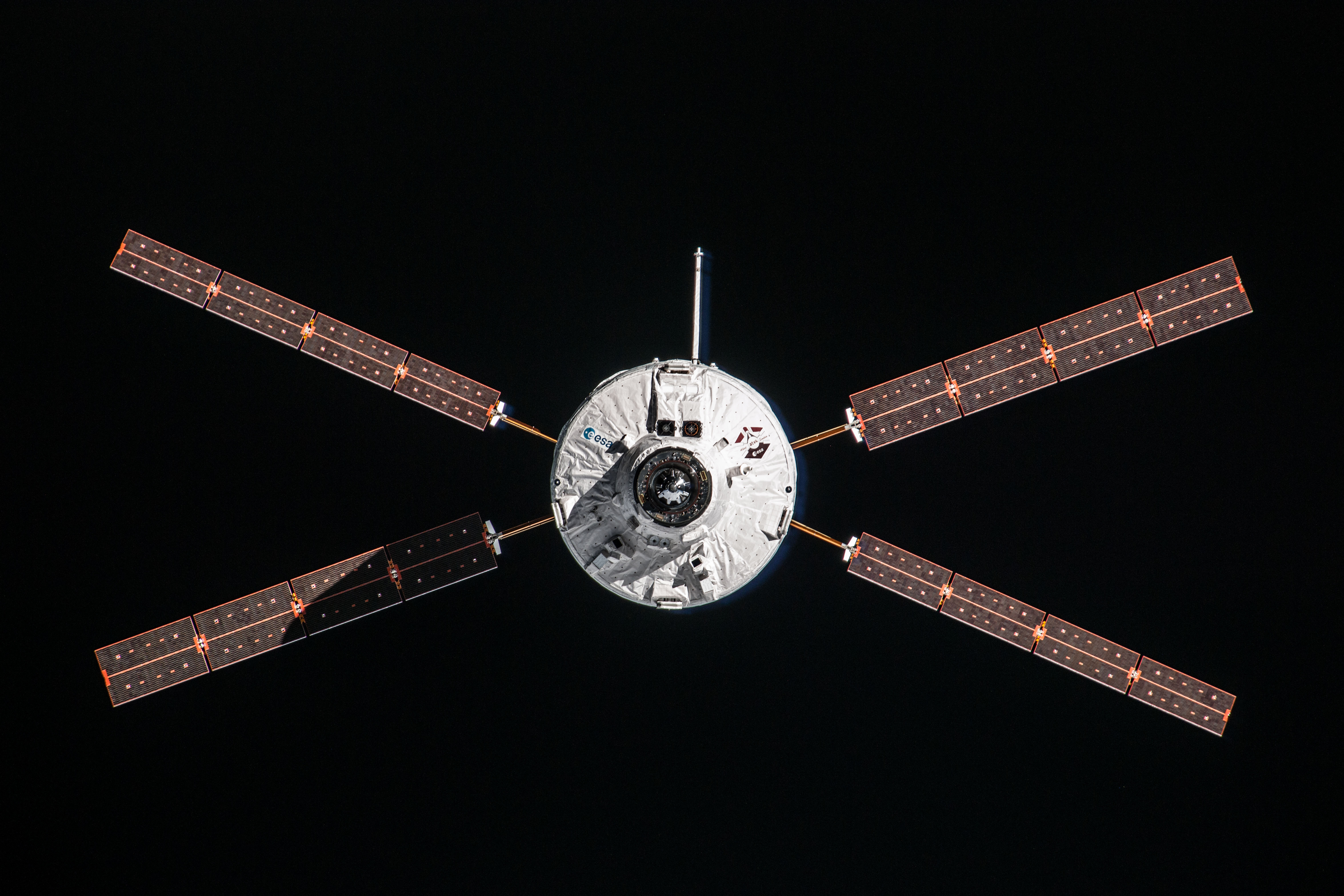

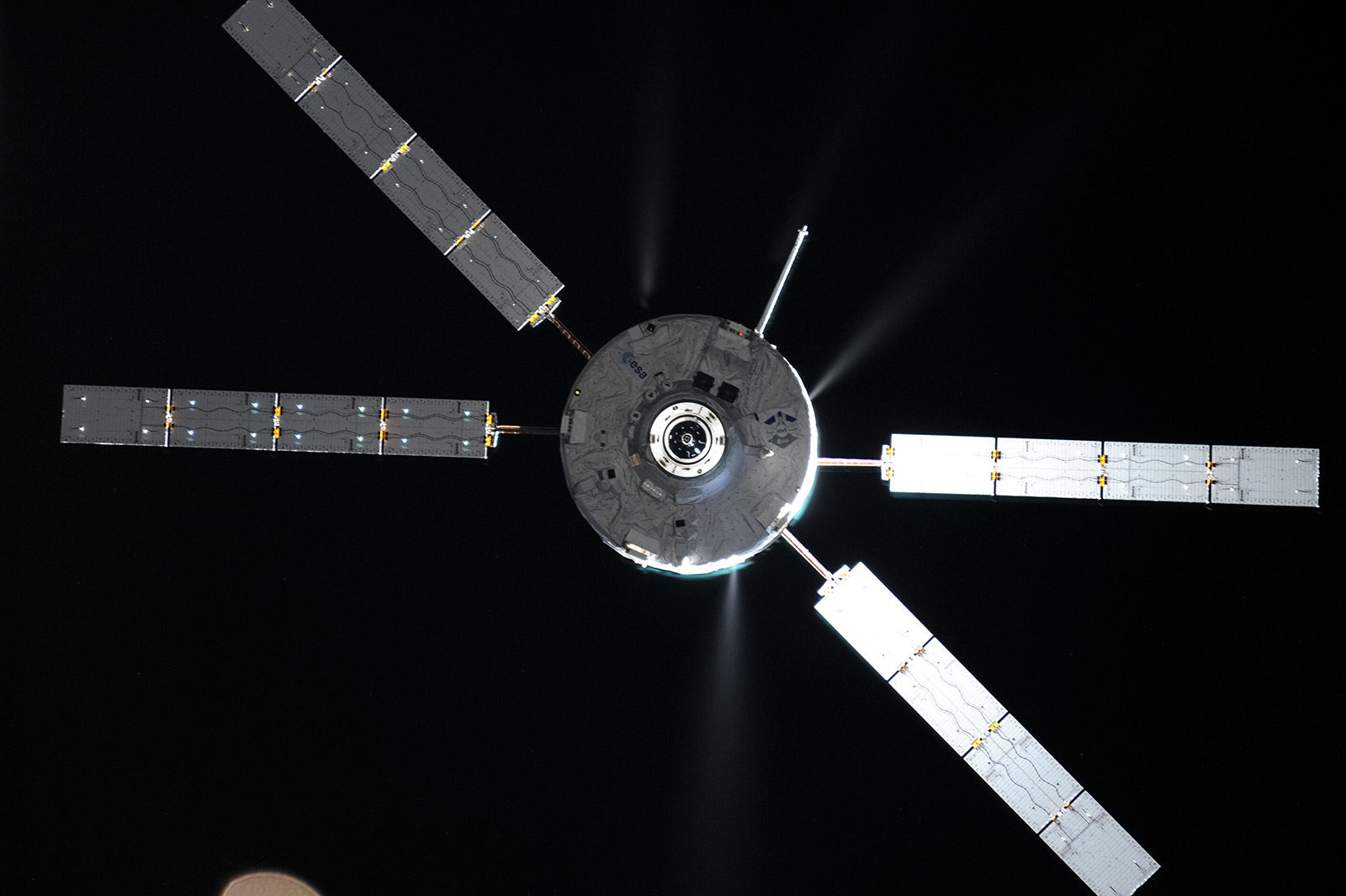

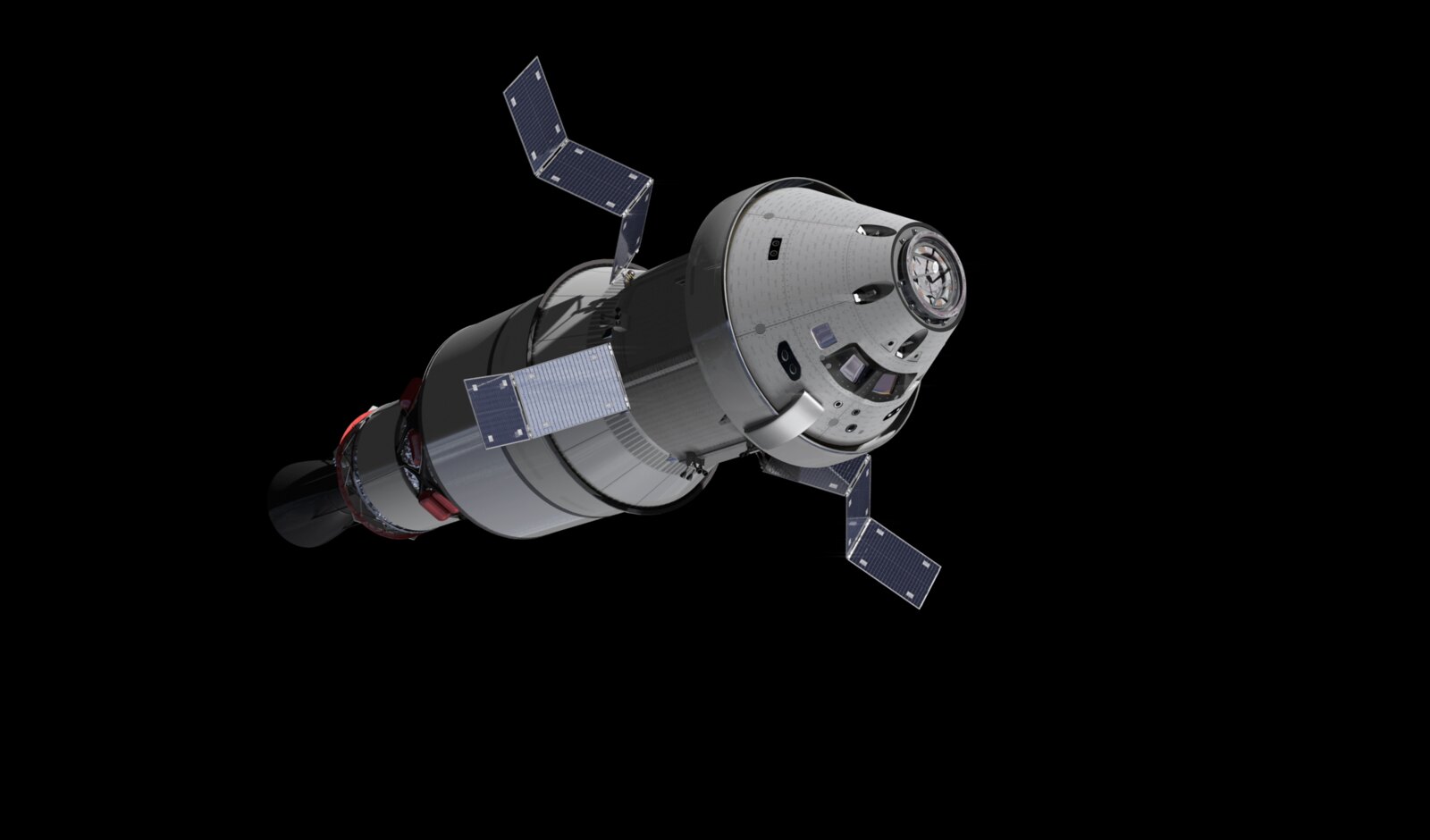

The voyage of our reconstituted art-meteorite took a significant step closer to space last week when it was prepared and coated to be space (re-)worthy. To recap the voyage so far: a piece of the Campo del Cielo meteorite that fell to Earth over 5000 years ago was bought by artist Katie Paterson, based in Berlin. She took a mould of her piece of space rock, melted down the meteorite and reformed an exact copy. Now the rock has a new destination: the International Space Station via transport ship ATV George Lemaître that will be launched next year.

Materials and electrical components laboratory at ESTEC, The Netherlands

Before the meteorite-art can be sent to Earth’s space laboratory however, it needs to be prepared for safety at ESA’s Materials Space Evaluation and Radiation Effects laboratories at ESTEC, The Netherlands.

On a fine Dutch morning, ESA’s Space Station Logistics Engineer Bram Bekooy and Materials and Processes expert Marika Orlandi inspected the meteorite one last time.

Bram Bekooy measuring the meteorite

Its precise measurements and weight were recorded and a plan of action was decided upon: thorough cleaning to get rid of corrosion, vacuum treating the iron rock at 100°C for an hour, coating the piece of art in a protective silicone-based varnish and curing at 100°C.

The vacuum-cooking makes sure that any moisture on the meteorite’s surface is literally sucked off. Better to do this on Earth (where we can open the window to the laboratory and get some fresh air) rather than on the International Space Station where particles could build up and clog filters or even cause health problems for astronauts.

Catalin Fotea graciously agreed to help out on this project, providing a change of tasks from his usual role analysing and testing space-materials.

Cleaning Campo del Cielo

Step-by-step

A paint job is only as good as its preparatory work, so rust and dirt must be carefully scraped off with a brush, space-worthy dental tools and a grinder. Once clean, blow away all remaining dust and rust with high-pressure air.

In the vacuum oven

Water and other volatile materials must be dealt with during an hour’s treatment in the vacuum oven at 100°C.

While the meteorite is vacuum-cooked, prepare the coating. Mix one part hardener to nine parts space-grade silicone compound. Stir vigorously until a smooth opaque mix is achieved. Pop the mixture in a vacuum chamber to outgas. Repeat until a clear liquid is achieved.

[youtube saLUkOEljYc]

Applying coating

Remove meteorite from vacuum oven after one hour and allow to cool.

Apply previously prepared silicone mixture thoroughly to all surfaces, nooks and crannies. Place coated meteorite in preheated oven for curing at 100°C for one hour, or alternatively leave at room temperature for a few days.

Voilà

And there you have it!

After curing

A safe, space-certified meteorite. With Catalina’s help and equipment, we went through the process in less than half a day.

The meteorite was placed in a zip-lock bag and is on its way to Turin, Italy, for loading onto ATV-5.

Next destination: space… first via plane to Europe’s Space Port in French Guiana and then on to ATV-5 cargo’s module to the International Space Station.

Ready again for space

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: 2 comments

i hope this meteorite will be released from the ISS to fall a 2nd time to earth.

Hello I live in Istanbul city of Turkey. My relatives living in Kazakhstan has an average of 240 kilograms of meteorite in her hand. I have Meteor pictures and the analysis report. If you want I can send. We are looking for buyers. We want $ 60 for 1 gram. If you are interested please write your response.

Best Regards

Huseyin GUL