The 1970’s Viking landers dug long trenches that, at their deepest point, reached 15 cm. This remains the record depth for collecting martiansoil samples for analysis. The corers of Curiosity and Perseverance rovers can drill 7 cm into rocks and soils.

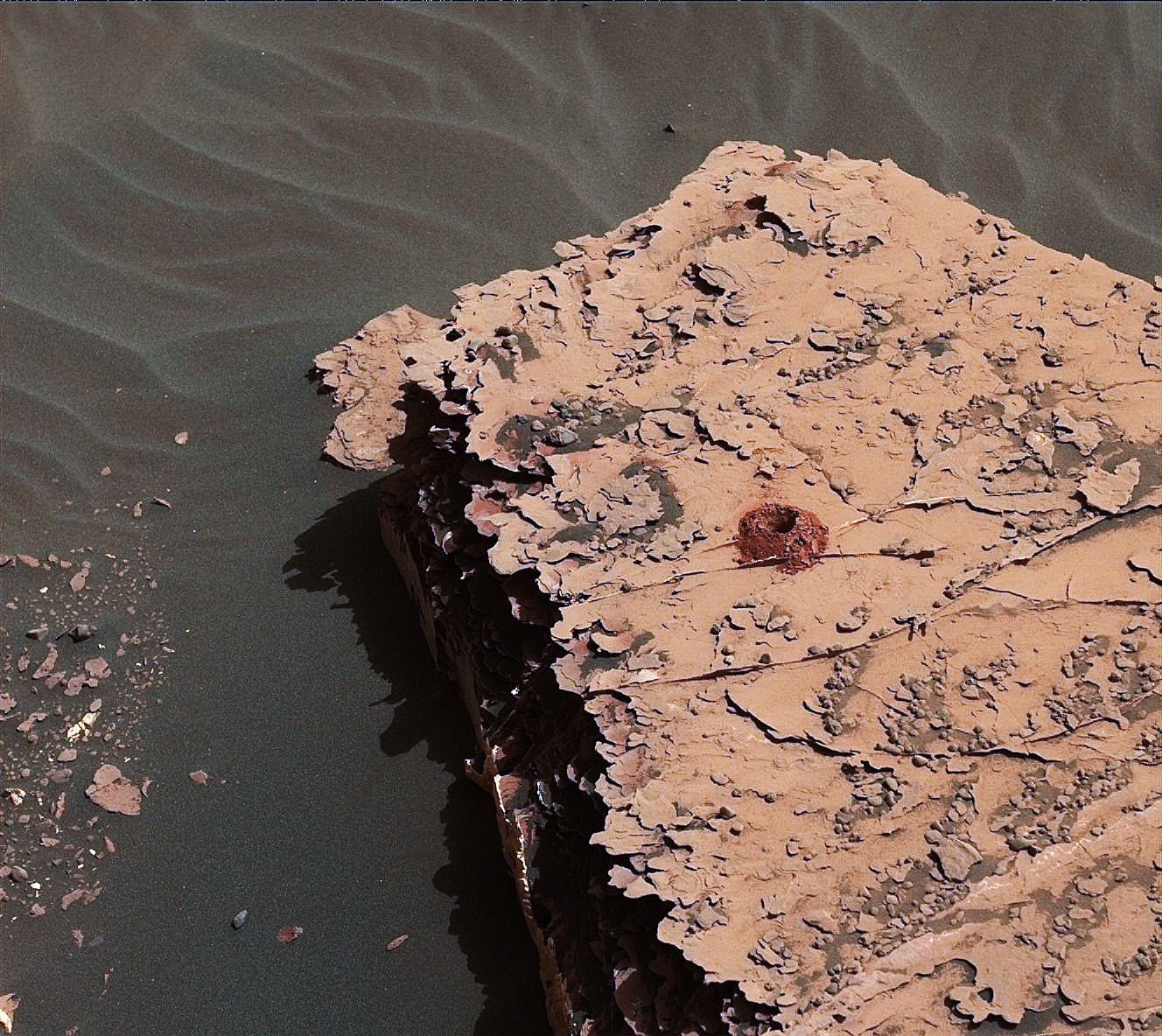

NASA’s Curiosity rover successfully drilled a hole 5 cm deep in 2018. Credits: NASA/JPL-Caltech/MSSS

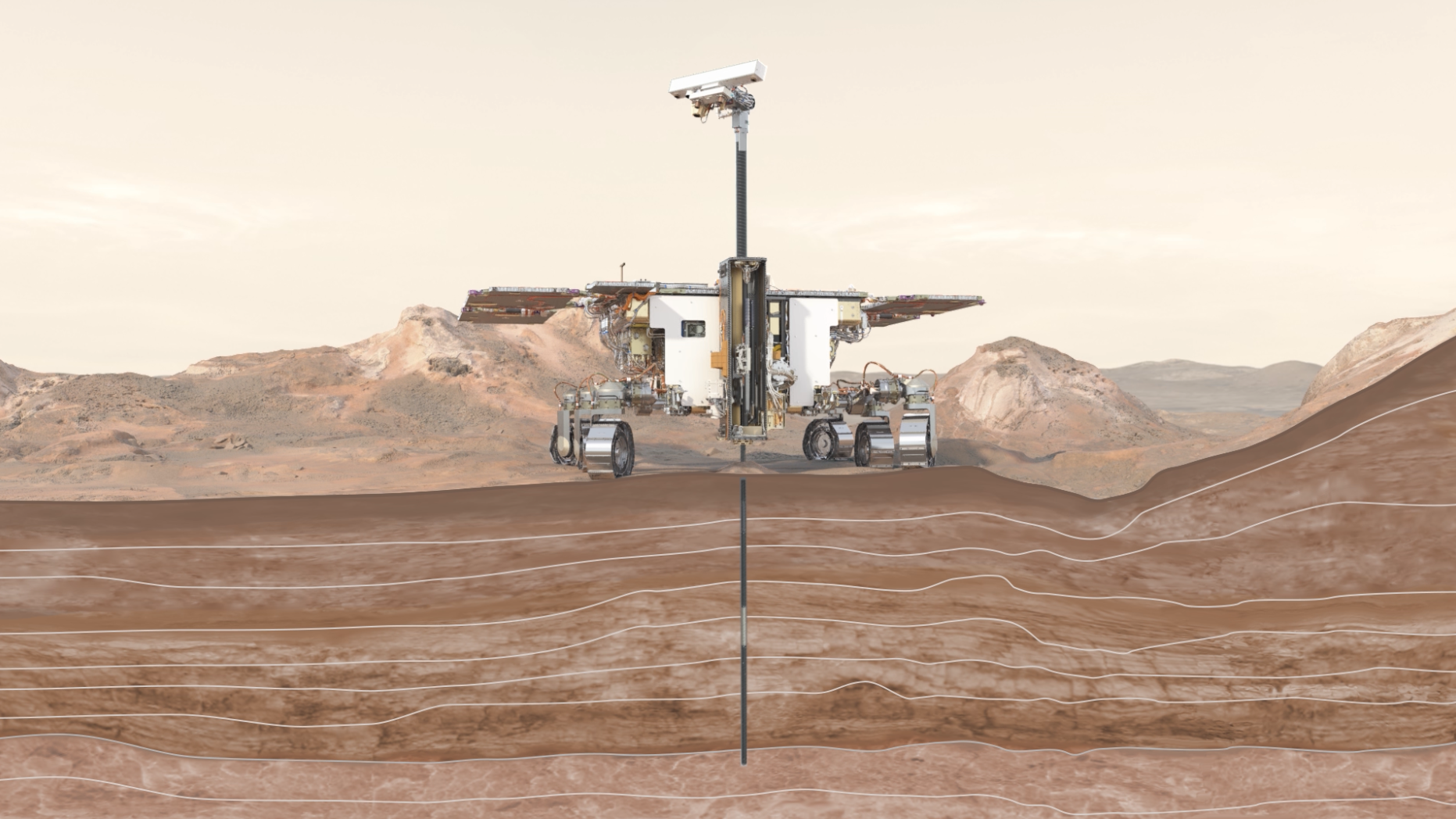

Rosalind’s drill can reach a depth of two metres, some 20 times deeper than any other mission on Mars.

What lies beneath

The drill’s extension stems from the mission scientists’ objective to study possible biomolecules. The research community wants to dig deep to access well-preserved organic material from four billion years ago, when conditions on the surface of Mars were more like those on infant Earth.

The reliable acquisition of deep samples is key for ExoMars’ main science objective: to investigate the chemical composition – and possible signs of life – of soil that has not been subjected to damaging ionising radiation.

Drill operations

The ExoMars drill is an assembly of mechanisms that rely on an automated choreography of tools and three extension rods. This episode shows how these are fitted to form a ‘drill string’ capable of reaching the full length of two metres when all are connected.

A motorised mandrel rotates and pushes the drill tool into the ground. The mandrel then leaves the tool on the ground secured with a lower clamp and ascends to connect an extension rod for the drill to penetrate deeper. An overall length of 2 m is reached by repeating this operation with the other extension rods. To cope with potential jams, the drill system includes a back-up drill tool.

Power and performance

Rosalind Franklin’s drill rotates at approximately 60 revolutions per minute, depending on soil consistency. The drill is designed to penetrate surfaces as hard as marble.

Drilling on hard terrains to a depth of two metres on a mobile platform, using less than 100 watts of electrical power, is a complex task that requires time. The drill’s speed varies greatly depending on the material. In loose or sandy soil, it can advance rapidly at 30 millimetres per minute. However, when drilling through hard clay, progress slows to just 0.3 millimetres per minute.

Assuming a typical depth penetration of 50 cm per martian day or sol, the sampling process could take several days depending on the desired drill depth. This explains why carefully choosing where to drill is crucial.

Down the borehole

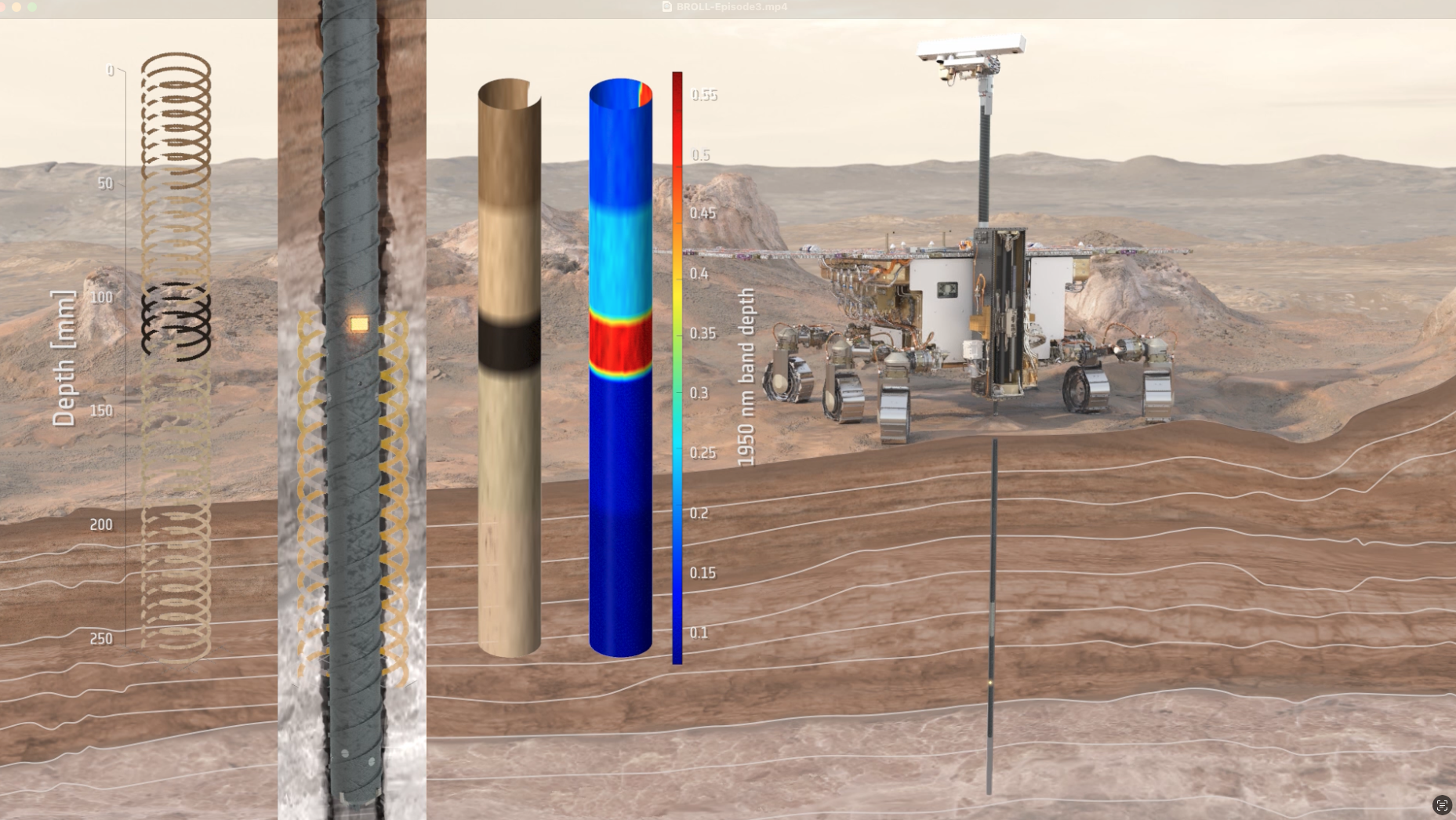

As the rover drills, it will simultaneously investigate the borehole’s mineralogy with infrared spectroscopy.

The movie shows how the Ma_MISS imaging spectrometer studies the borehole stratigraphy while the drill string is being extracted. The instrument can also be used while the drill is going down.

Through a small sapphire window in the drill, an infrared lamp illuminates the wall. The light reflected off the wall’s mineral grains is collected through the same window and focused onto an optical fibre to travel up the drill string until it reaches the spectrometer. Teams on Earth use the data to build a mineralogy map.

The next crucial step is securing the sample.

Capture

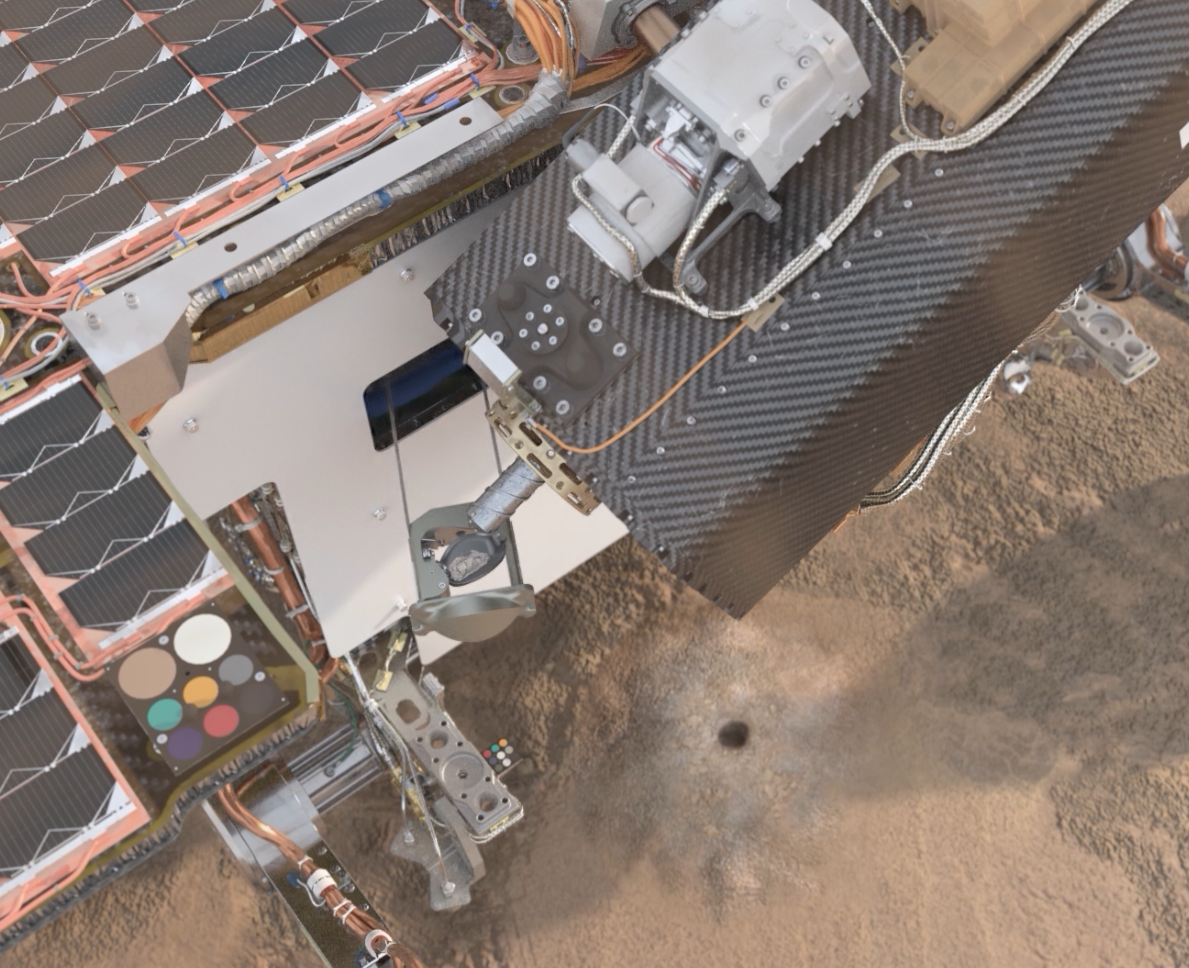

Rosalind Franklin’s drill captures and retains the sample with a shutter that prevents it from dropping out during retrieval. The sample is typically a pellet of 1 cm in diameter and 2.5 cm long. It may be whole, or fragmented, but it can also be a mix of loose soil and grains. This is why being able to close the drill’s chamber is so important.

Once the sample is secure, the drill brings it back to the surface. The string is dismounted and stored. The drill box is elevated and rotated to drop the sample into a special drawer at the front of the rover.

As shown in Episode 2, several cameras image the sample on the drawer, which then withdraws to deposit the sample into a crushing station.

Next up: Episode 4, Precious Sampling, that shows what happens to the sample inside the rover’s sophisticated analytical laboratory.

Stay tuned to learn more about this amazing machine with the Rosalind Franklin rover series.

Discussion: 3 comments

Intrigued that the drill head rotation is only once per second, when on Earth drills rotate far faster. What’s the rationale for such a low speed? Is it maybe something to do with the low gravity and stability of the rover, or maybe the expected soil consistency? Thanks, Keith

Hello, Keith. Thanks for being curious. The rotation speed dis for energy limitations and efficiency reasons. Rosalind Franklin drills slowly and as consequence, it may take a long time (estimated 50cm depth penetration per day). On Earth, power drill tools need more than 10 times what is available to Rosalind Franklin drill.

There are additional advantages to drilling slowly:

– It is more unlikely that you will get stuck.

– It gives the auger more time to evacuate the drill fines (the auger is the helicoid on the side of the drill that transports fines out of the borehole).

– The sample does not heat up —better for preservation of organics.

It may be a little strange, but i would love to read the FMEA for a drill on Mars!