ESA’s Earth Return Orbiter will rely on the thrust of its Orbit Insertion Module to perform this critical manoeuvre.

Steadily but surely, this module has been making significant progress in 2025 for a future trip from Earth to Mars.

Bringing the orbiter to destination

The Orbit Insertion Module (OIM) is the Earth Return Orbiter’s high-thrust propulsion stage, designed to execute the decisive orbital insertion manoeuvre that transitions the spacecraft from interplanetary cruise into a stable Mars orbit. This manoeuvre is critical: it must be performed with precision and the right speed to ensure the orbiter can safely operate around the Red Planet.

Unlike the orbiter, which relies on electric propulsion delivering low thrust over a long period during the long cruise phase, the OIM is equipped with chemical propulsion capable of delivering rapid and powerful thrust.

This distinction is essential in orbital mechanics; while electric propulsion excels at efficient, gradual orbit changes over months, the final insertion burn demands a short, high-impulse manoeuvre that only chemical engines can provide.

The staging between the two propulsion systems is carefully orchestrated. During the cruise phase, the orbiter’s electric thrusters handle fine-tuned trajectory corrections and deep-space navigation.

As the orbiter approaches Mars, control transitions to the OIM, which performs the high-thrust burn required to decelerate and capture the spacecraft into its target orbit around Mars. After placing the orbiter in the required trajectory, the OIM will detach. Like a rocket stage being ejected, this will reduce the orbiter’s mass, improving the electric propulsion efficiency.

The OIM will remain in martian orbit for more than 50 years, minimising the risk of contamination from Earth to Mars.

From paper to hardware

The OIM team reached several critical milestones this past year:

- Critical Design Review which confirmed the maturity of the design and cleared the path for full-scale integration.

- Propulsion Interface Unit qualification tests.

- Engineering Qualification Model delivery to the Avionics Verification Model, marking a major step for the validation of the system.

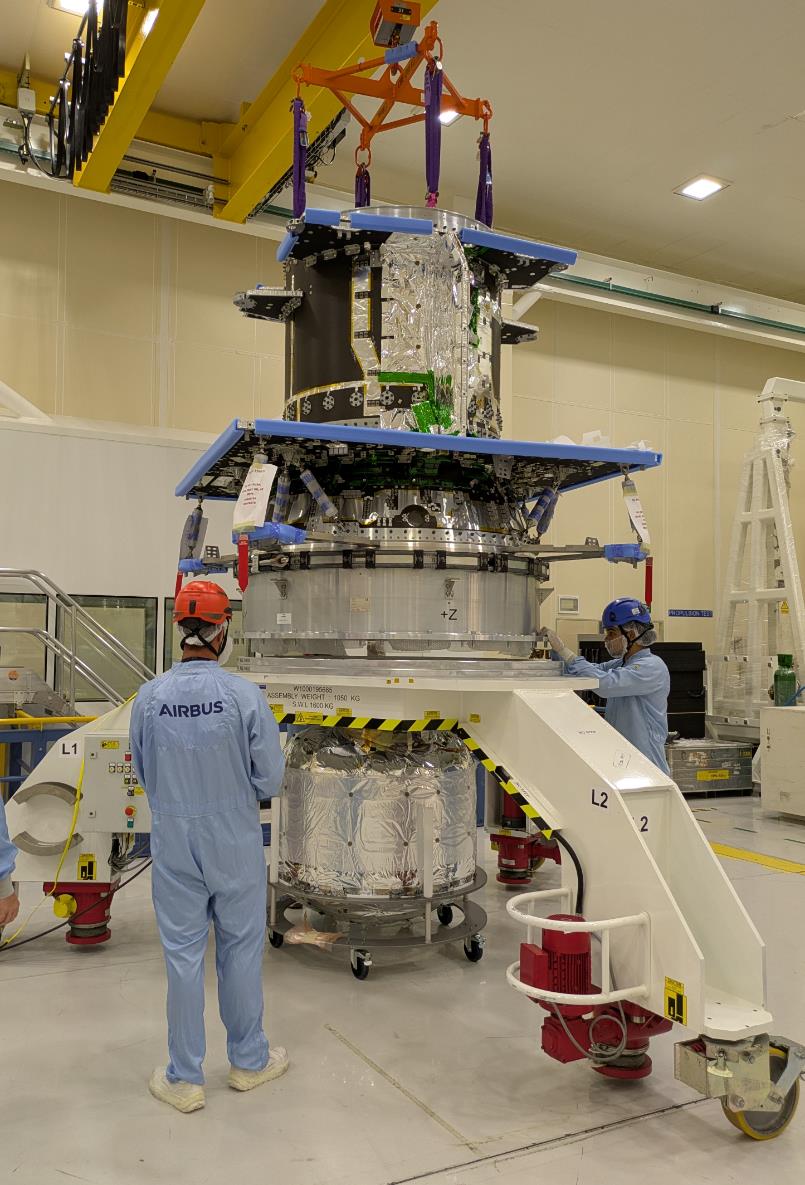

- OIM structure transfer from Thales Alenia Space in Italy to the Airbus facilities in the UK.

- Integration of the Chemical Propulsion System has begun.

These achievements reflect a steady transition from design and analysis to the assembly, integration and testing of flight hardware.

Smart bridge between systems

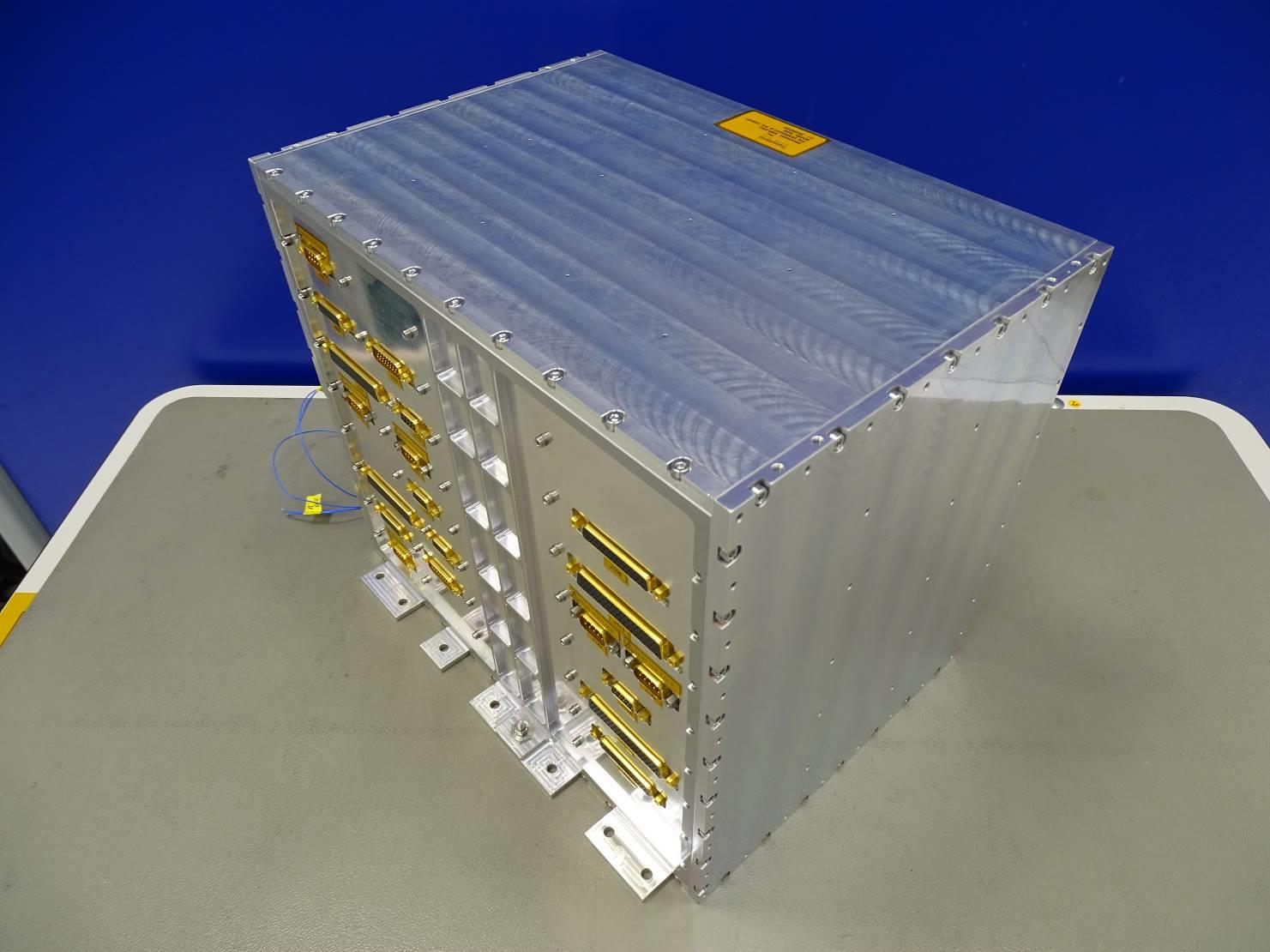

At the heart of the OIM’s functionality lies the Propulsion Interface Unit (PIU), a key avionics component that acts as the intelligent bridge between the orbiter’s central computer and the OIM propulsion subsystems.

The PIU manages the distribution of power and control signals to the thrusters, valves and heaters, ensuring that each manoeuvre is executed with precision and reliability.

For the Earth Return Orbiter, this interface plays a critical role in coordinating propulsion commands during orbital insertion and trajectory corrections. It enables autonomous thermal regulation and fault detection, safeguarding the module’s health throughout the entire mission.

Its qualification and integration into the ERO Avionics Verification Model this year marked a major step toward flight readiness.

Engineering the backbone

The OIM’s structural evolution has been nothing short of remarkable. By mid-2024, the flight model central structure was fitted with support panels and brackets for tanks, propulsion thrusters and solar array interfaces.

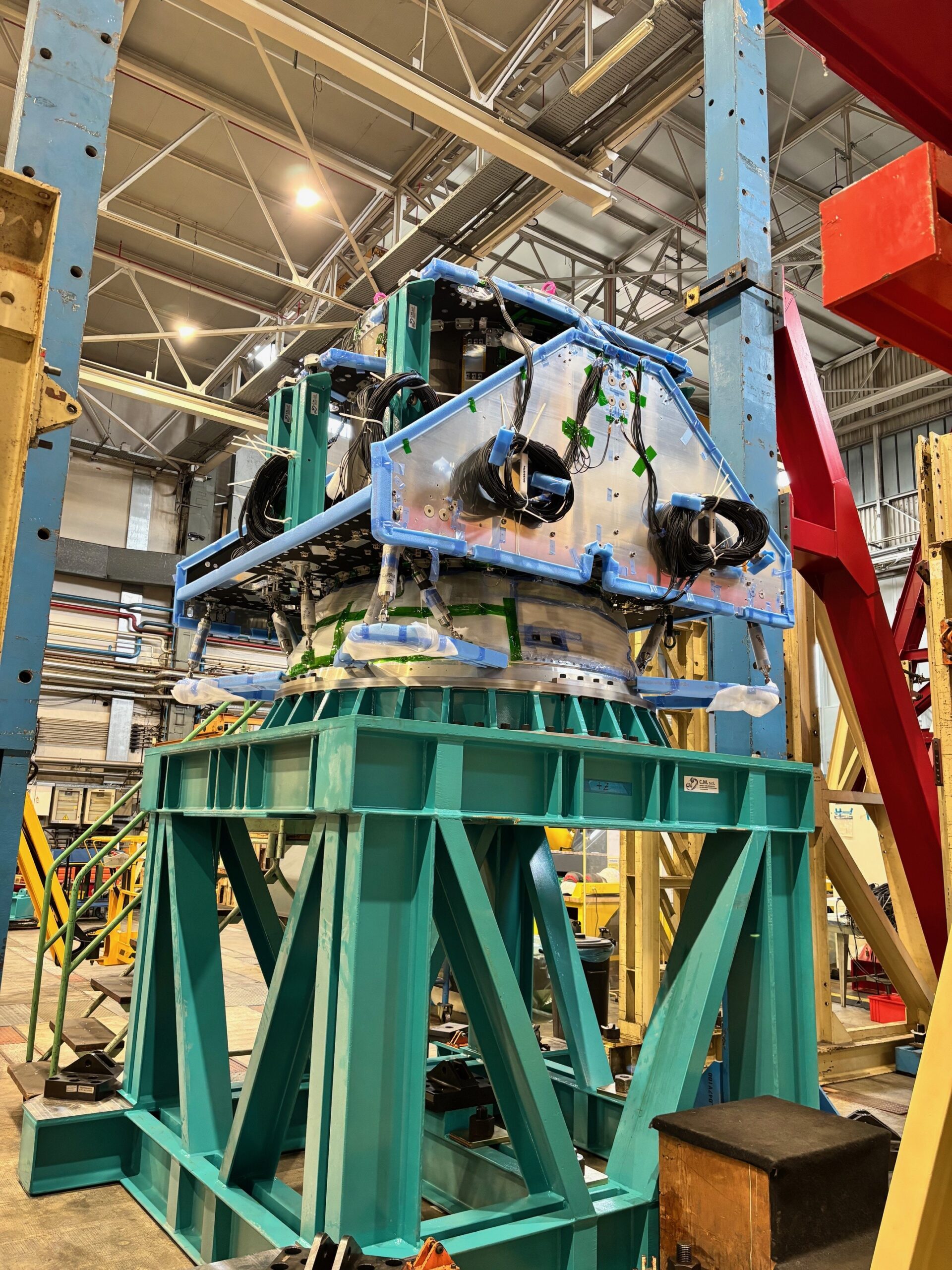

Orbit Insertion Module primary structure installation for the Static Load Test. Credit: Thales Alenia Space

These components form the mechanical spine of the module, and their successful assembly marked a major leap forward in readiness, which culminated in a successful Structure Static Load Test.

During this test, the OIM structure has been subjected to external loads, which simulate the accelerations and vibrations imposed by the rocket’s ascent through the atmosphere into space during launch.

A complex set of hydraulic jacks was controlled to apply loads in different locations simultaneously, while the response of the structure was accurately measured with hundreds of strain gauges and displacement transducers.

Thrusting the Orbit Insertion Module

The OIM is equipped with a pressurised bi-propellant Chemical Propulsion System, with high-thrust engines for the orbit insertion and reaction control thrusters for attitude control.

With the OIM structure fully manufactured and tested to verify that it is capable of enduring the harsh environment of the launch, it is ready to receive the critical elements of the propulsion system. In 2025, various components, such as valves, piping, filters and tanks will be integrated into the OIM structure.

The first element to be integrated will be the internal tank, as it is the largest component but also the most hidden one, right in the middle of the central tube.

Looking ahead

In the next months, teams will proceed with OIM integration activities and additional testing to support the Earth Return Orbiter mission.

Stay tuned!

By Stéphane Langlois, Orbit Insertion Module Systems Engineer

Discussion: no comments