Albert Einstein at the patent office in Bern. Credits: Swiss Federal Institute of Intellectual Property

Continuing our series on countries’ contributions to ATV, let’s look at Switzerland. The mountain country is often associated with Albert Einstein who lends his name to ATV-4. The scientist famously worked in a patent office in Bern while he wrote many papers including his ground-breaking Special Theory of Relativity.

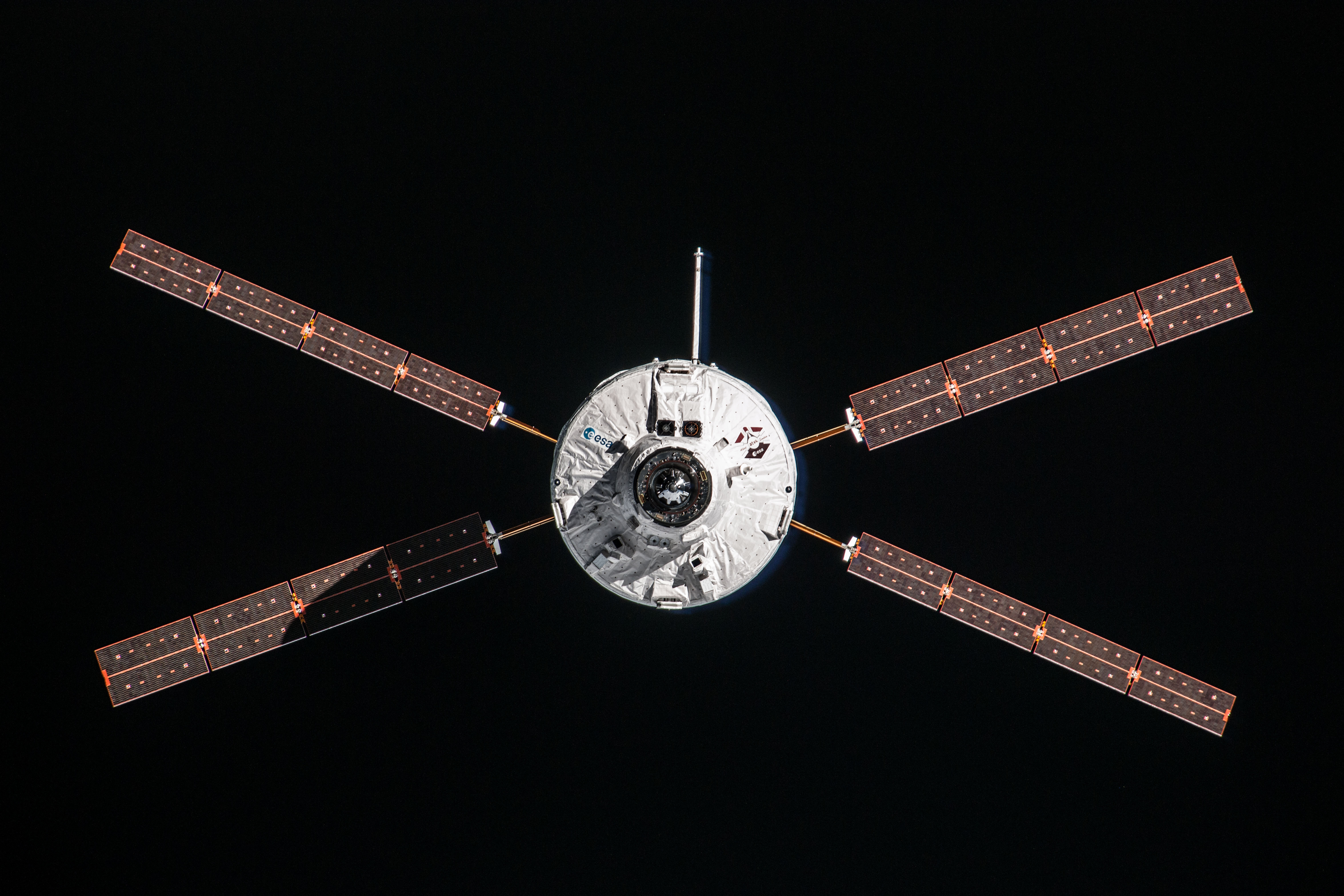

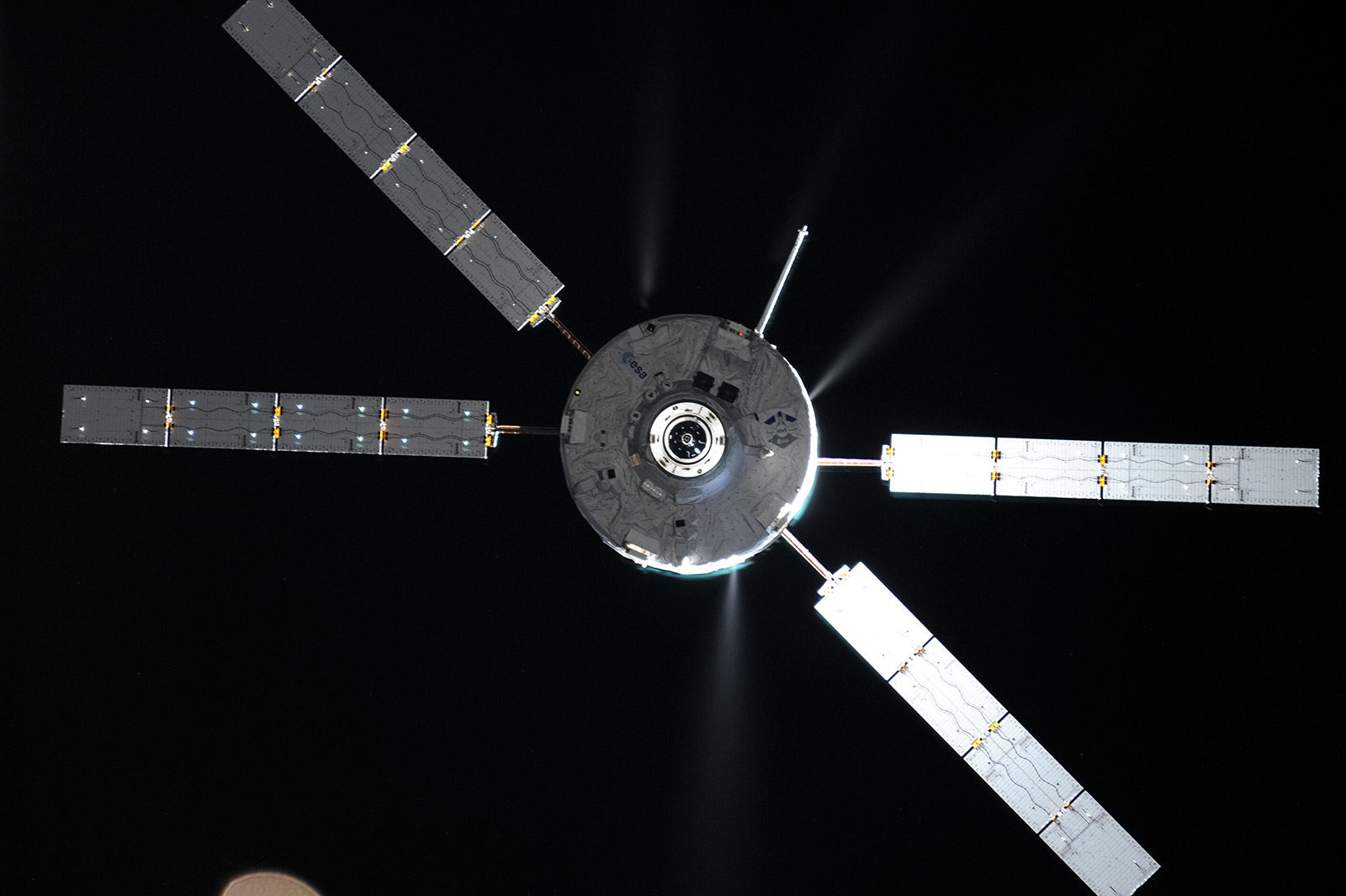

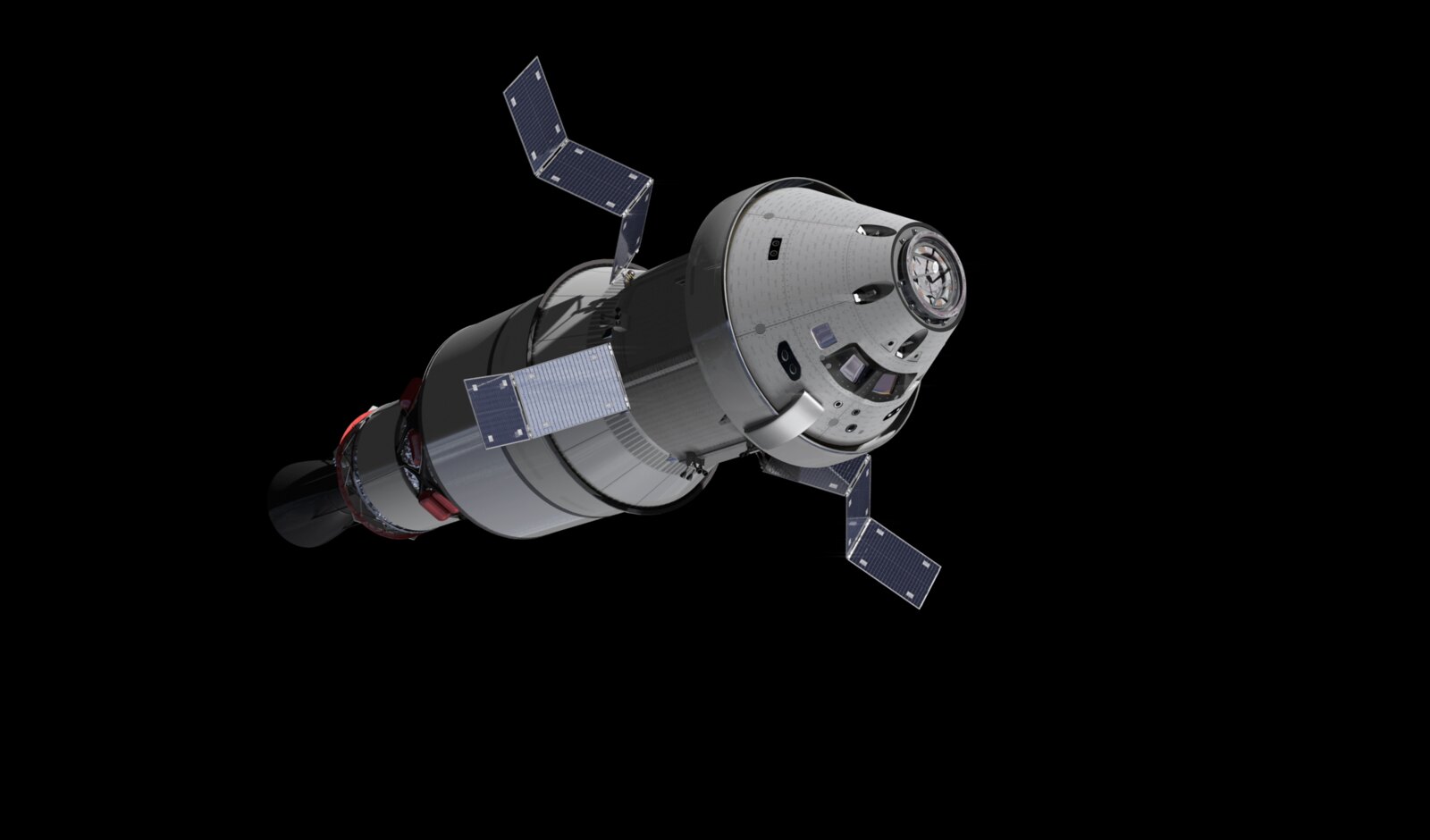

Ruag space, based in Zurich, contributed the basic structural elements of ATV, and that is not to be taken lightly, as they were designed to be as low-mass as possible. In space flight, mass equals cost as more fuel is needed to propel heavier objects into orbit.

The racks that hold ATV’s cargo are made of aluminium and comply with NASA’s standard sizes: the Internal Subrack Interface Standard and the Mid-Deck Locker. Weighing in at only 92 kgs, Ruag’s racks can hold 750 kg of equipment and will still stand strong after enduring more than 12,5 g. This means that up 9375 kg can be supported by only 92 kg of structure, more sturdy than your average bookshelf!

Ruag also supplied the Solar Array Deployment Mechanism, the equipment that unfolds the solar panels after launch. They were not chosen at random, and their ‘sun panel-deployer’ proved itself on the Hubble telescope in 1990.

A regular star of this blog is also made in Switzerland: the LCAM, or Late Cargo Access Means, that allows cargo to be added to an ATV just before launch. Apco, based in the canton of Vaud, took care of the MGSE or Mechanical Ground Support Equipment on ATV.

In addition, Apco supplied ATV’s armoured coating, protecting the precious spacecraft from dangerous micrometeorites and space debris. In space terms this is called the MDPS (Meteorite and Debris Protection Shields), an acronym that, surprisingly, is easy to understand.

Micrometeorites and space debris are serious threats to spacecraft. Travelling at speeds of up to 72 km per second, the impact of a flick of dried paint can have serious effects. ATV uses a so-called Whipple Shield, which comprises a double layer of armour placed at a distance from ATV’s outer skin. Any objects that strike the shield break into fragments on impact with the outer protective shield layer, and then the inner layer stops anything from penetrating into the vessel and its mission critical hardware.

Credits: Syderal SA

Lastly, SYDERAL, based in Berne, provides four thermal control units to keep ATV operating at its optimum temperature. The units monitor and control the batteries and report directly to ATV’s platform computer. The system is designed to be fail-safe and has multiple redundancies, which is why SYDERAL supplies four of the units per ATV.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: no comments