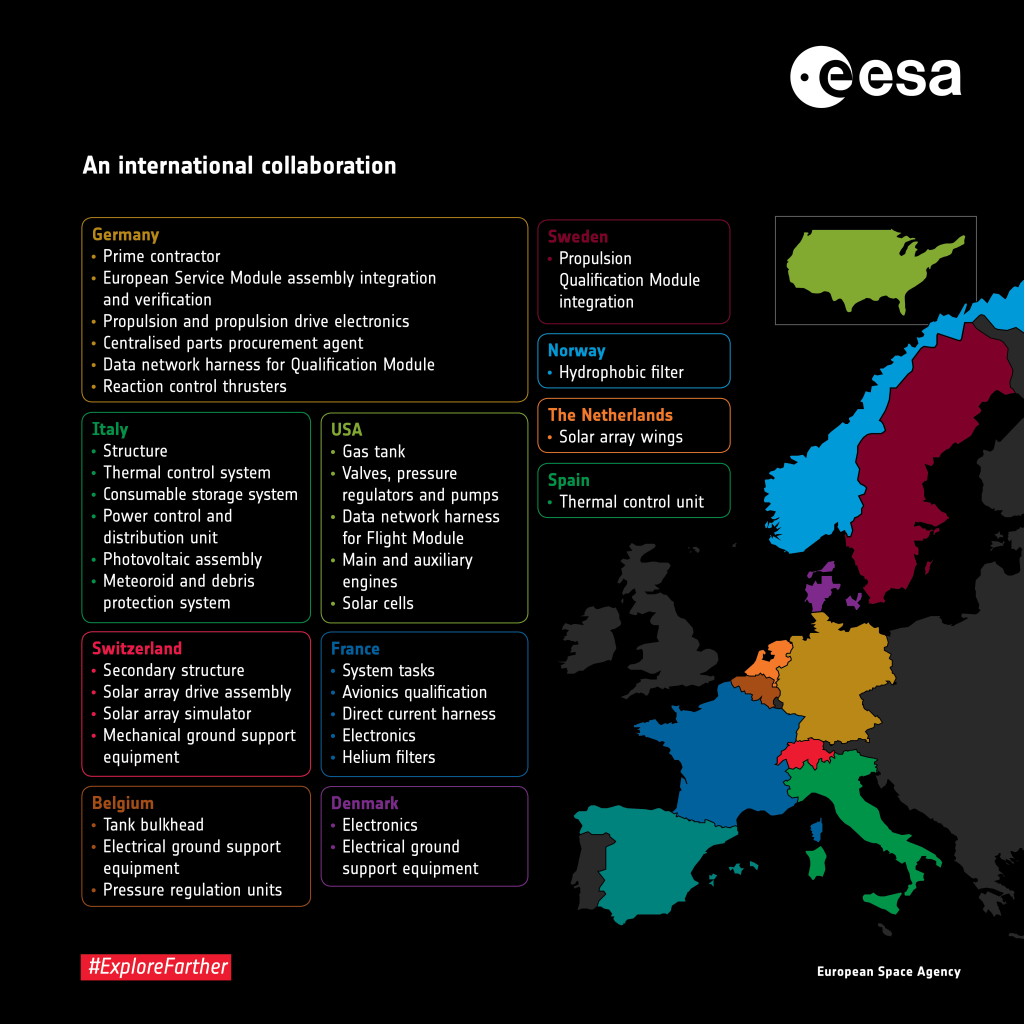

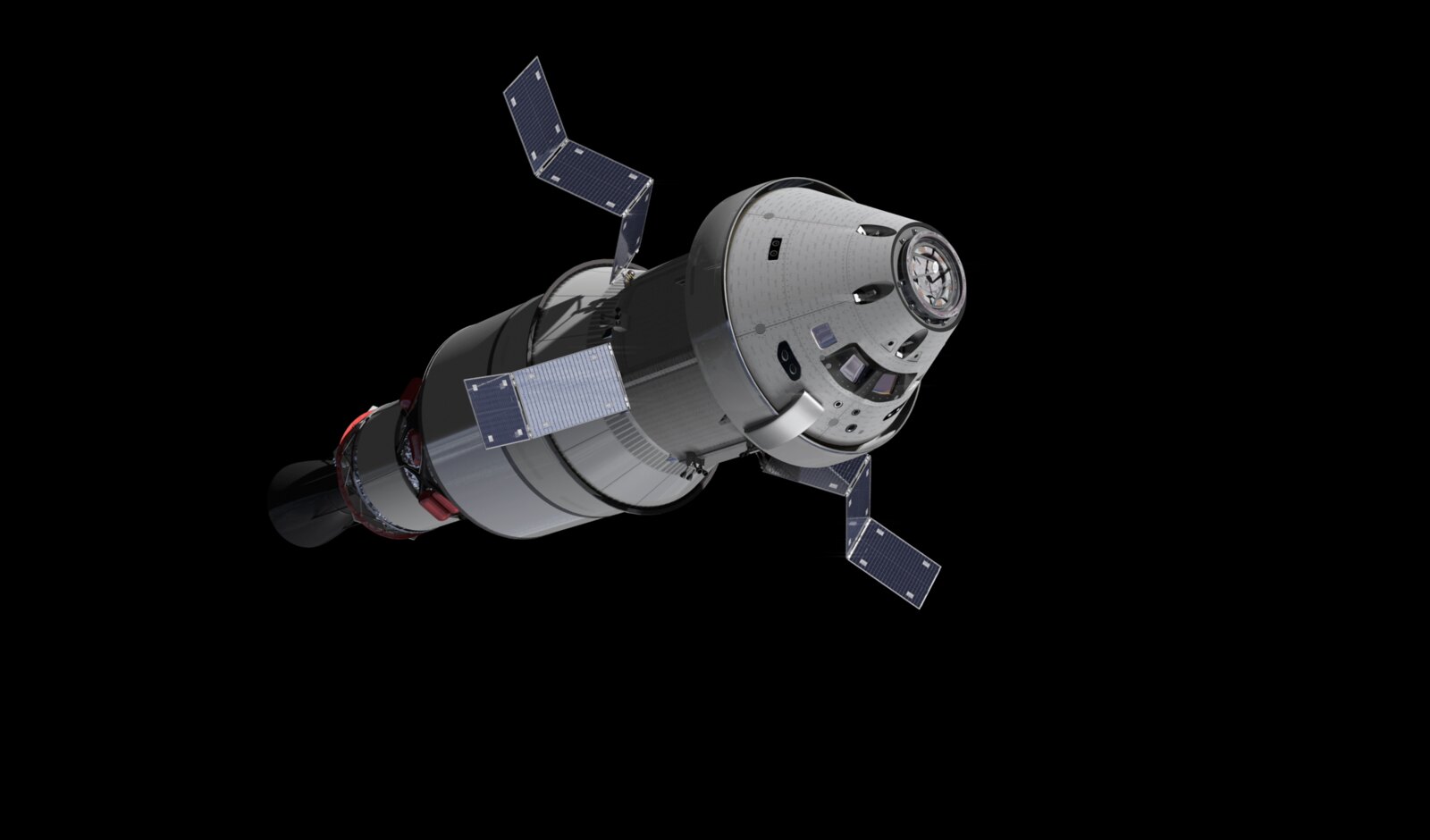

The European Service Modules that will power Orion to the Moon and back are made from 20 000 parts and components, built in ten countries around Europe and the USA. Following on from the ATV – Made in… series let’s look in-depth at what each country is contributing, starting, in no particular order, with Denmark.

Rovsing, founded in 1992 and based in Glostrup, is the only company representing Denmark for the European Service Module. Specialising in testing and simulations equipment, Rovsing provides Electrical Ground Support Equipment to support assembly and testing of the European Service Modules, both in Europe and in USA.

Simulated solar arrays

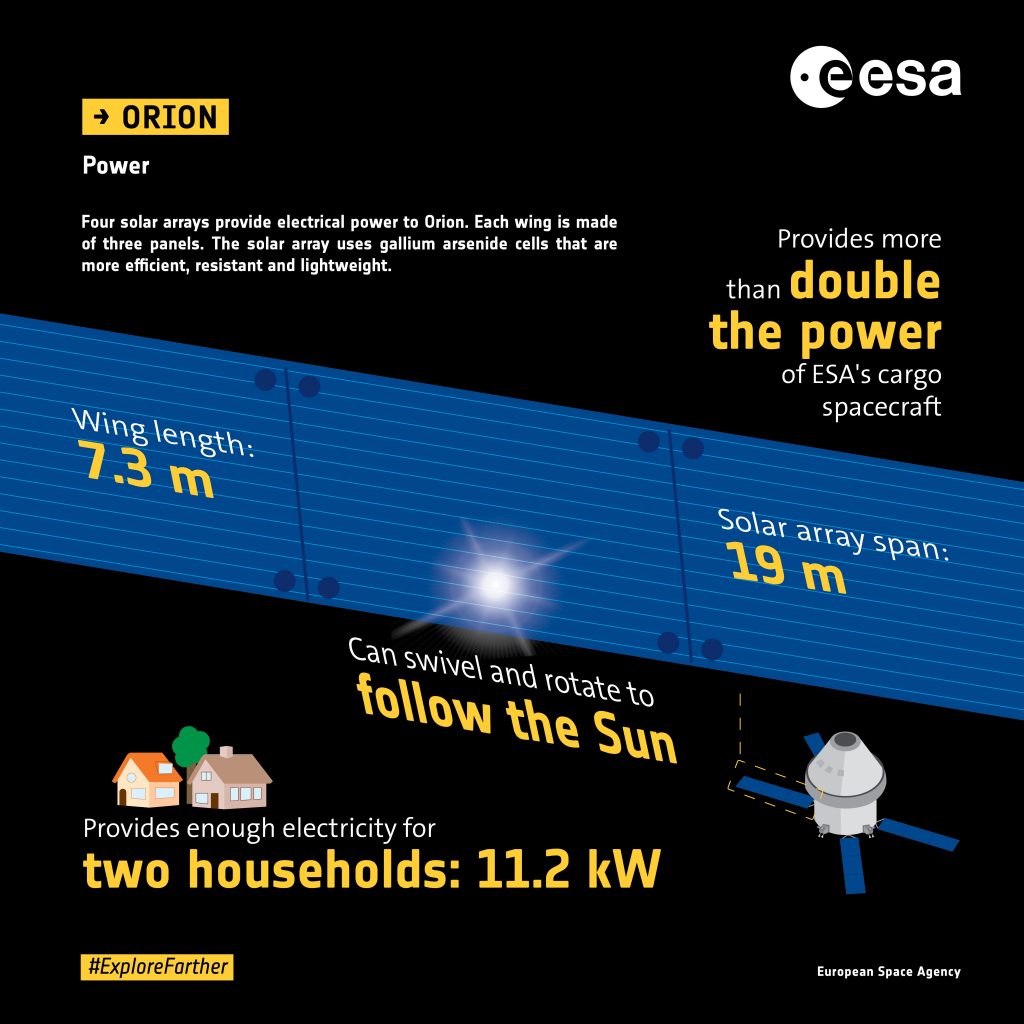

One of the larger contributions is the Solar Array Wing Front-End Equipment (shortened to SAW-FEE) used to supply electrical power to the European Service Module when not in space. Basically, the solar wings in a box, or more accurately in two massive racks on wheels, these high-power units generate the same type of electricity that Orion will benefit from once it unfolds the four solar wings in space – the equivalent of the electricity needs of two households.

During check-out and testing on ground a European Service Module is not simply plugged into the mains when it needs to be powered on. The Rovsing SAW-FEE simulators consist of two racks that produce the electricity needed by simulating the real solar arrays with the Rovsing RO-5100 Solar Array Simulator power supplies and also protect the service module and the whole Orion spacecraft during testing from any power surges with the RO-1010 second level protection units.

The supplied power emulates 36 individual solar panel sections, and a special piece of Rovsing hardware emulates additional sensors in the Solar Array Wings. These temperature sensors and feedback signals make it so the European Service Module isn’t able to tell the difference between being connected to the Rovsing units or the solar panels themselves when flying to the Moon.

Power distribution

The solar arrays, real or simulated, don’t deliver their electricity straight to the European Service Module but pass first through the Power Conditioning and Distribution Unit that regulates and sends the power to the right components. Here too Rovsing supplies the test equipment for these units and the software needed to run them. Together with the solar array simulators, Rovsing provides the complete set of tools needed to simulate a whole mission to the Moon and back – electrically speaking. From changes in amount of sunlight illuminating the solar panels to changes in battery charge levels – all aspects of a spaceflight travelling half a million km from Earth can be tested.

The hardware from Rovsing has extensive heritage on other European and international satellite missions. The RO-5100 unit was developed in collaboration with ESA’s Power Conditioning department based at ESA’s technical centre ESTEC in The Netherlands and as a best-in-class product and the first European offering, it has been used for the ExoMars, PLATO and FLEX missions as well as MetOp-SG weather satellites and by commercial satellite operators in the USA.

With only 25 people working full time at Rovsing their imprint on the European Service Module and Artemis is noteworthy. The teams are proud of their work and enrolled ESA’s Danish astronaut Andreas Mogensen to narrate this video on their work:

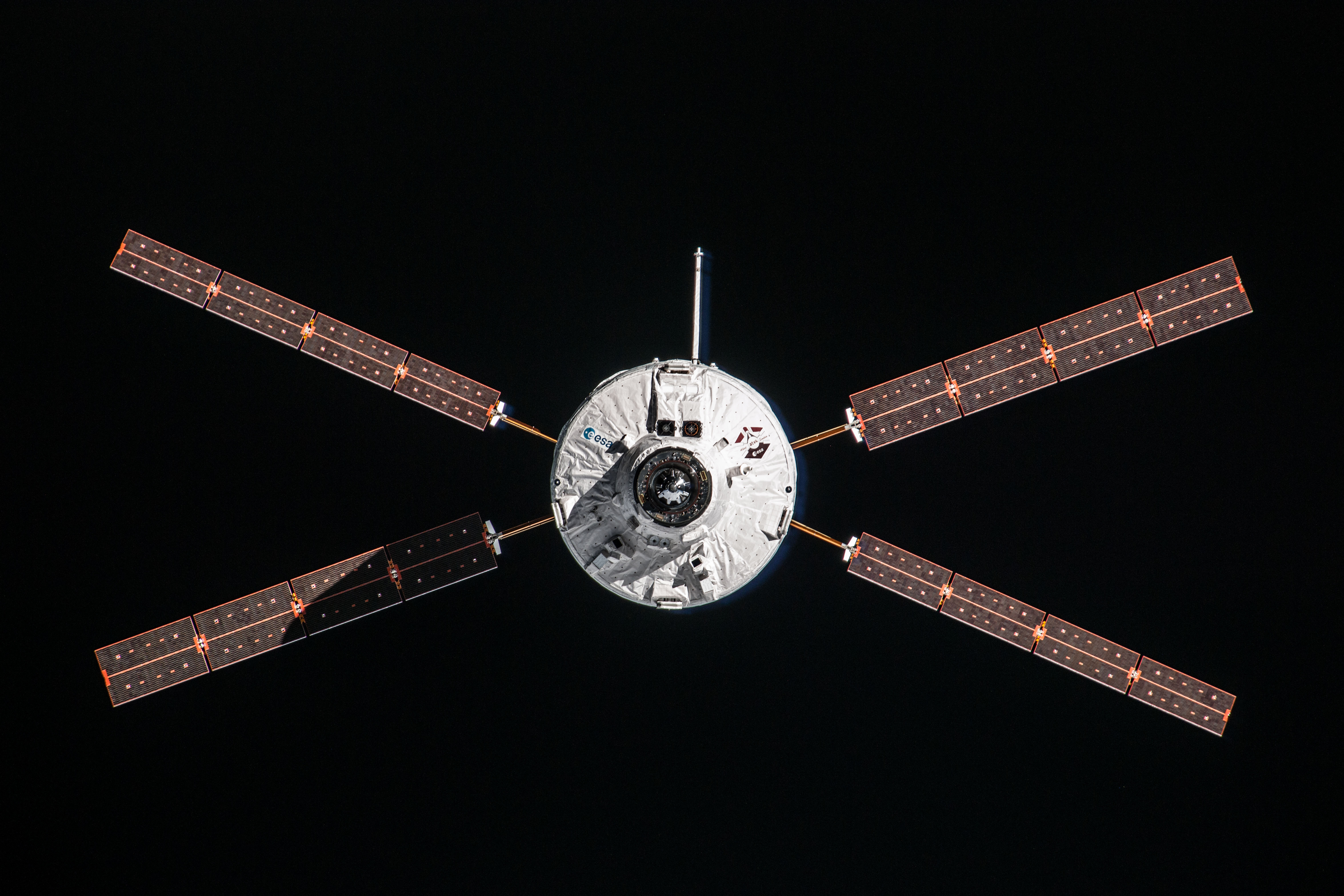

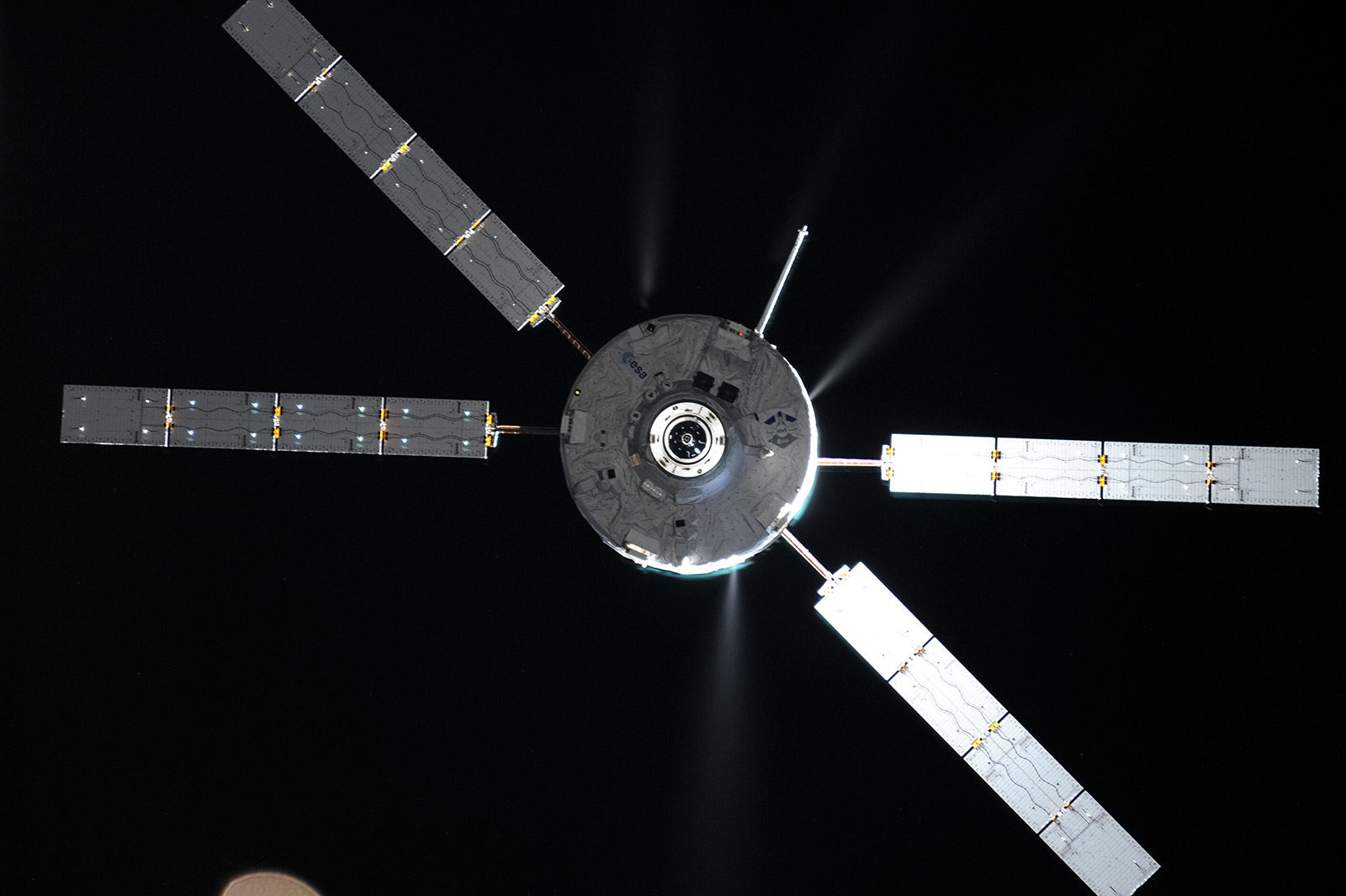

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: no comments