We checked in with Lionel Ferra, at EAC Cologne, and asked him for some background on a couple of his recent tweets:

Current config & attachment of #ATV5 hatch done by @Astro_Alex has been developed by ground team & @astro_paolo pic.twitter.com/cQP7S3ZpGH

— lionelferra (@lionelferra) August 26, 2014

and

as part of nominal ops to support Russian #EVA #ATV5 is now closed (ground picture) #BlueDot pic.twitter.com/yo66JmxYKI

— lionelferra (@lionelferra) August 18, 2014

Lionel sent in today’s guest post, describing details on how the hatch procedures have involved during the ATV missions.

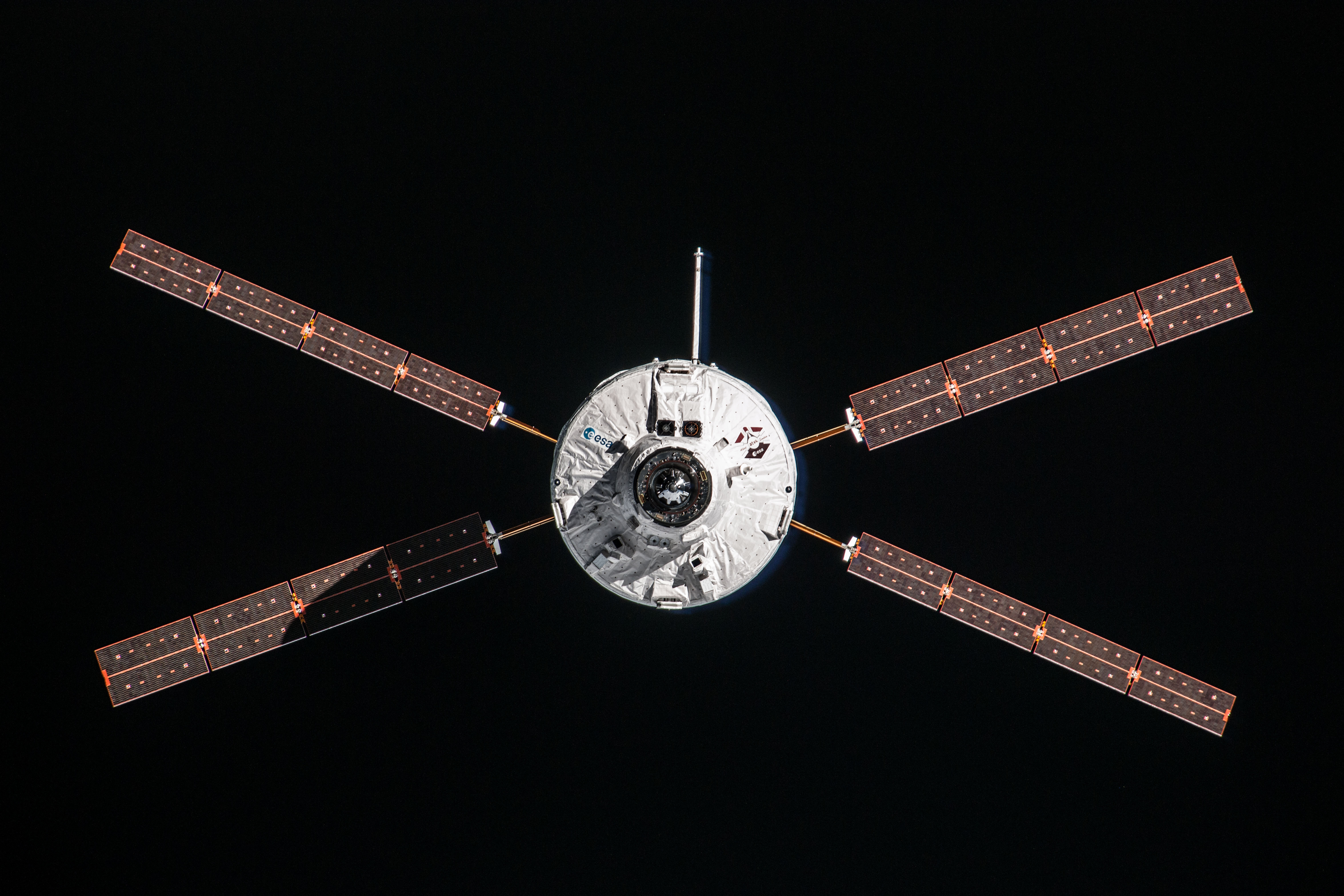

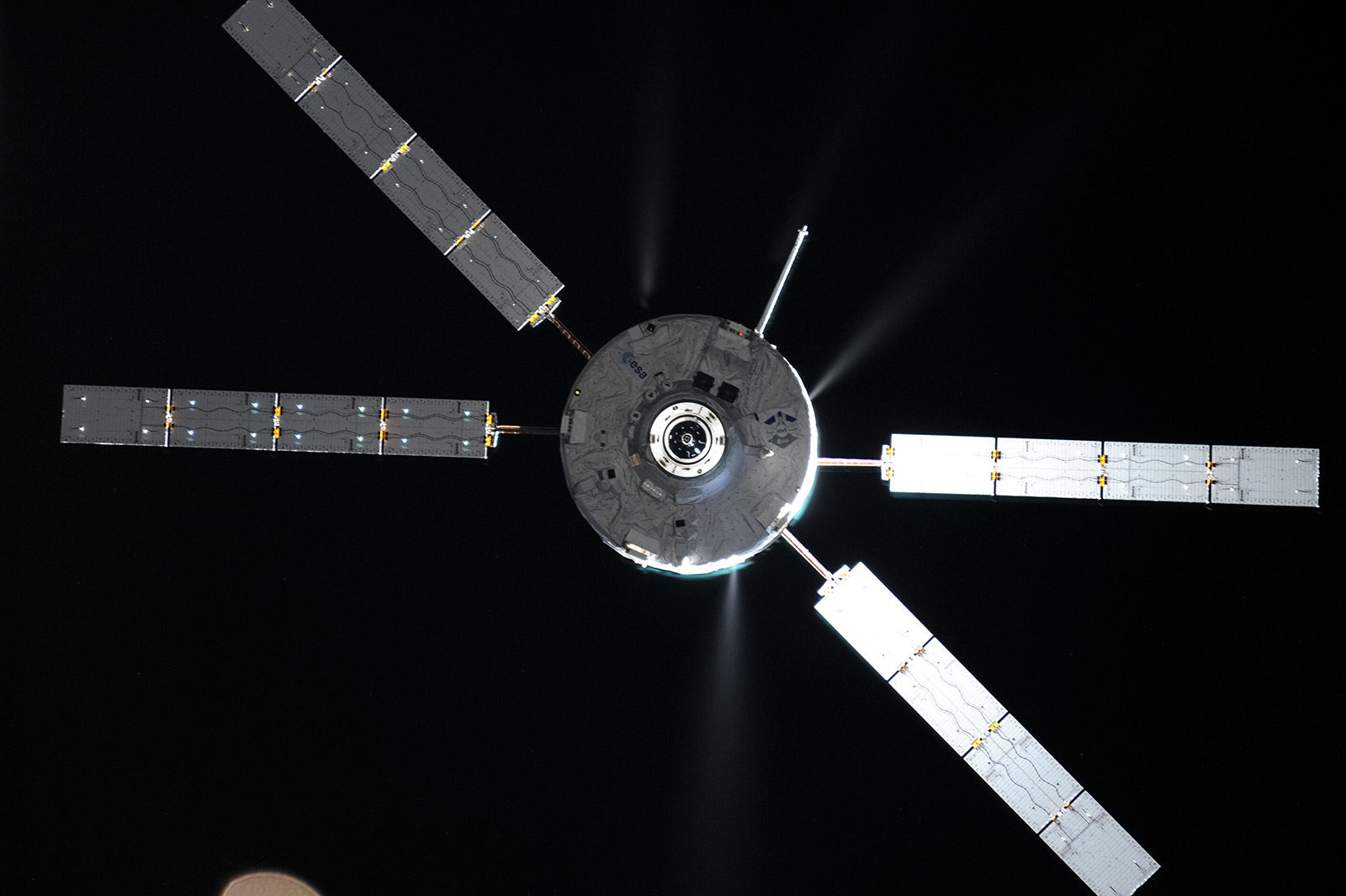

What is so peculiar about the way ATV-5 hatch was fixed by Alexander Gerst? Over the course of five ATVs, we have developed and upgrade several times the On-board Data Files (ODF), or procedures. Those documents are user manuals for any equipment on board, from operating an experiment to docking ATV.

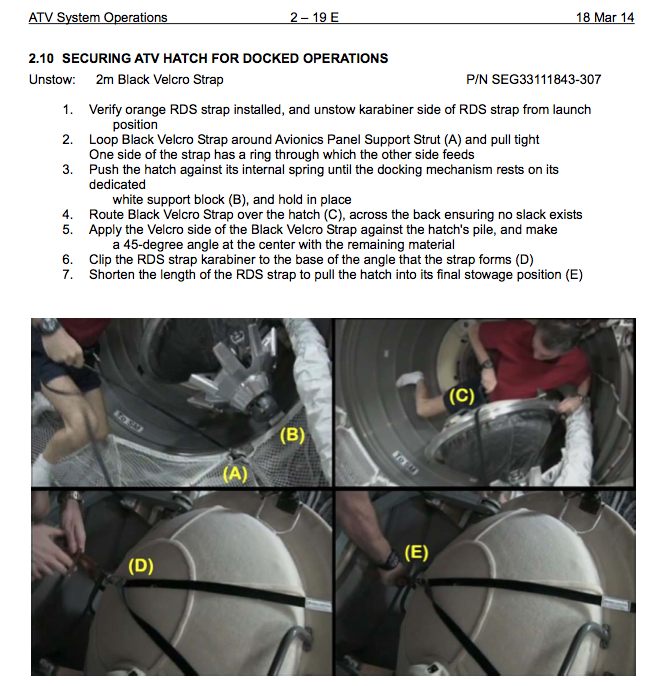

A part of the attached phase procedure for ATV is to permanently fix the hatch so that the crew can enter and exit ATV easily while enabling a quick closure in case we experience an emergency on board ISS or if it has to be closed for planned operations like the Russian EVA of last week.

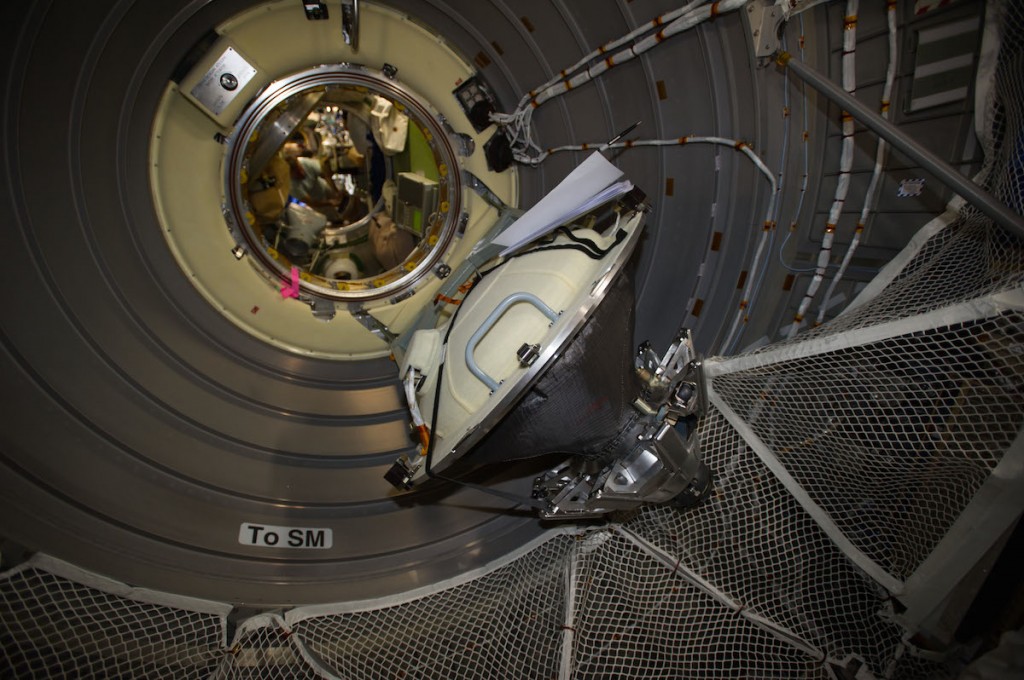

Back in 2011, when ATV-2 docked (see hatch above), it was quickly discovered that the hatch fixing strategy adopted for ATV-1 was not sufficiently stiff. Any time the crew entered and exited ATV-2, the delicate conical part of the docking system – and thus the hatch – bumped on one of the rods at the front part of the pressurized volume.

What simply needed to be done was to stiffen that attachment with more Velcro or straps avoiding this tiny wobble movement.

Indeed, a small dent was observed on the ATV-2 docking system after a few weeks in orbit due to this. This metal deformation was per se not a major issue but could have had some consequences in case ATV-2 would have to undock and then redock. All ATVs have been programmed and ground teams trained to execute this (unlikely) manoeuvre.

Nonetheless, ESA Astronaut Paolo Nespoli was asked to figure out a way to ‘rigidify’ the strapping while still not hindering a fast closure of the hatch. This was extensively photographed and filmed for the ground teams so that they could update the specific section of the ODF to reflect this new approach from ATV-3 onwards.

For various reasons, the ATV-3 hatch did not show the same signs of wobbling, so this standard easy fix was sufficient, as well, for ATV-4.

But the ‘Paolo’s procedure’ remained as part as the normal operations (as the traditional ATV-1 fixing method might again be potentially wobbling – see figure above). For ATV-5, Alexander Gerst and his fellow crew mates attached the hatch like for ATV-2 (see figures below).

We still yet don’t know if the easy fixing done for all other ATVs would have been sufficient; this would be a typical question for the debrief session once Astronaut Alex Gerst is back on Earth later this year.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: one comment

This is very informative Daniel. Apart from the Paolo’s procedure details, the images speak a lot themselves. This is the first time we actually saw an actual Black Velcro strap around the avionics panel strut.

Looking forward to more informative from you blogs. Here in Pakistan, we have very limited resources and a not yet born properly space program.