*Editors note: this blog post is an expanded version of the ATV cleaning article which first appeared here.

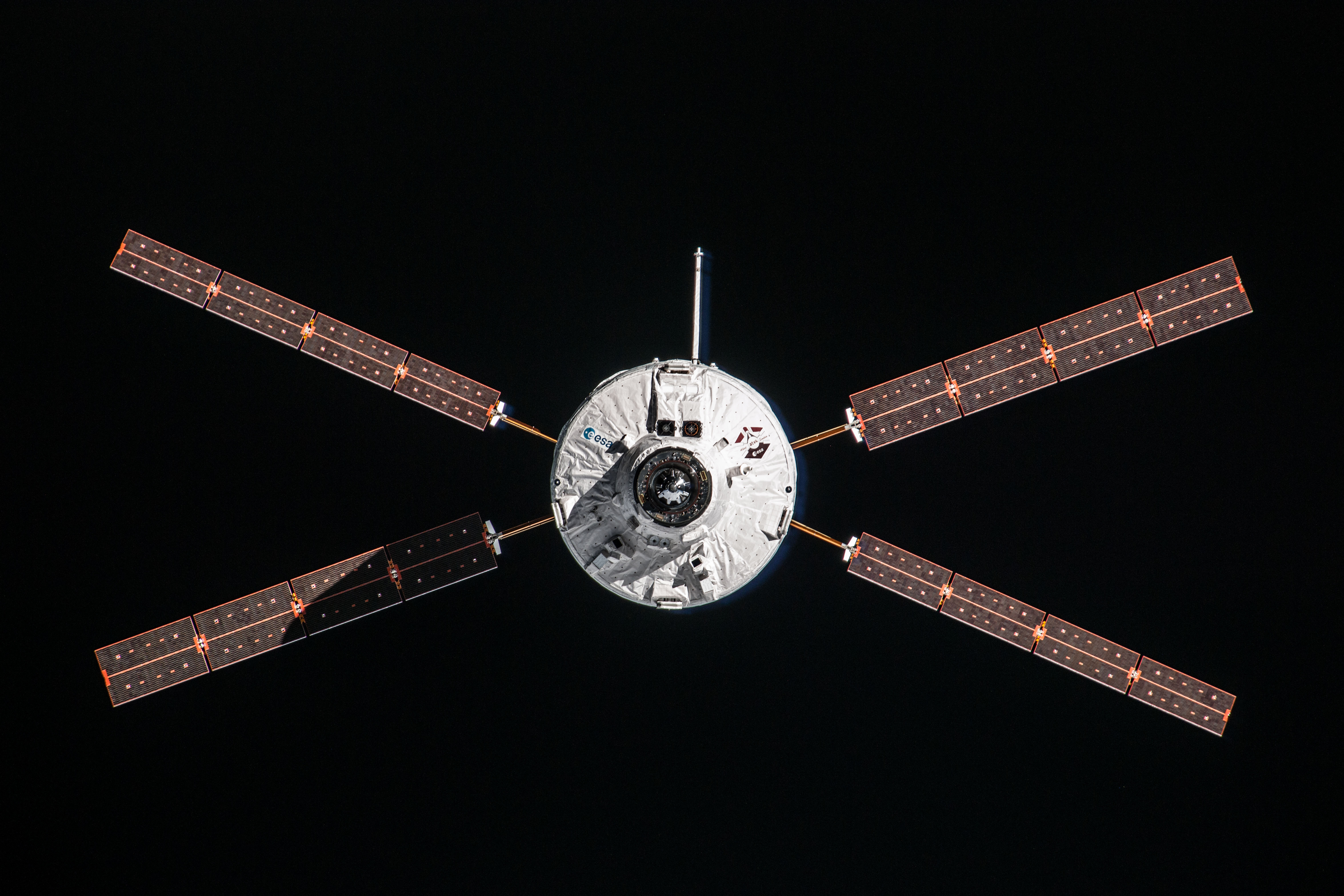

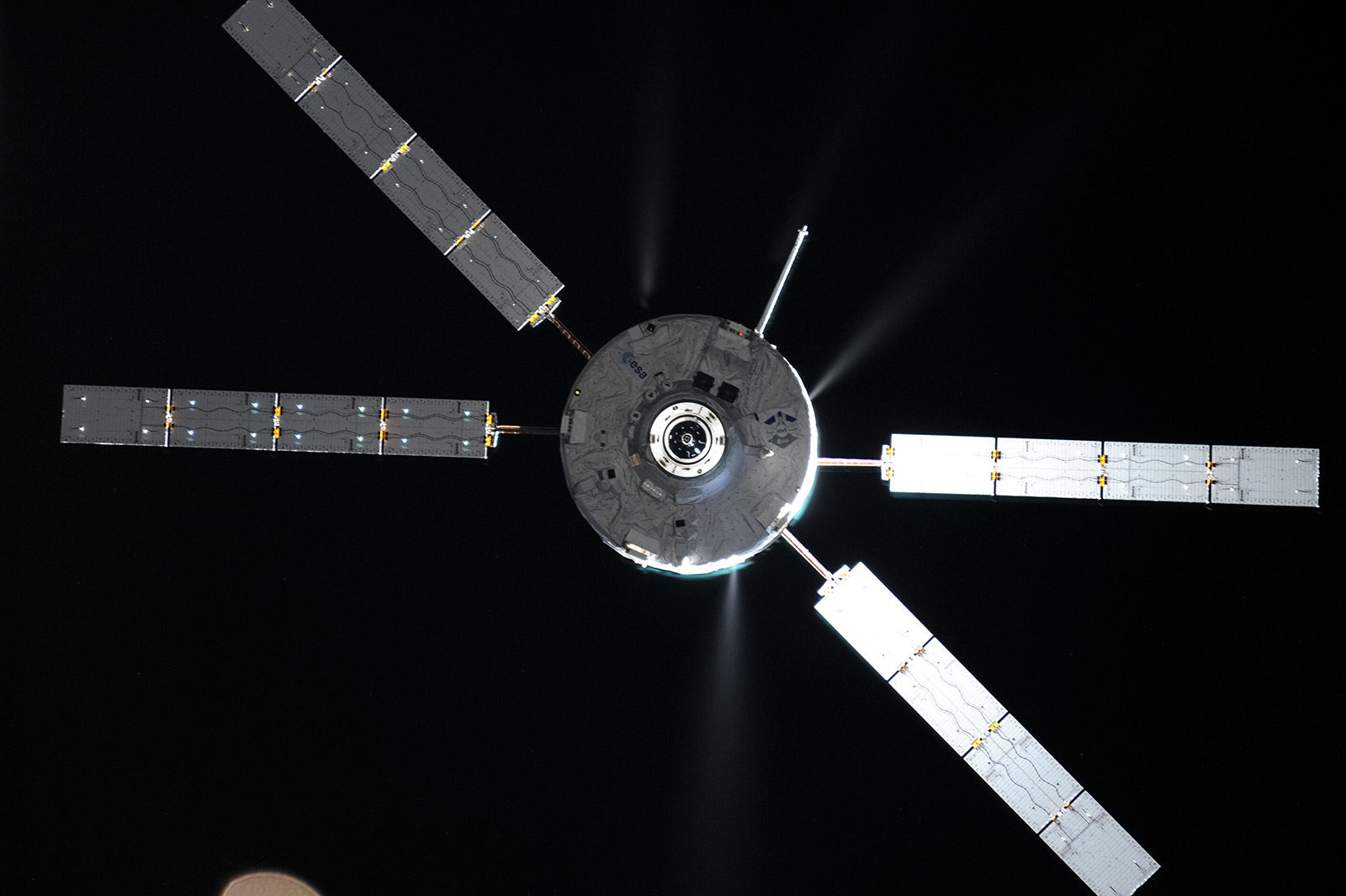

ESA’s latest ATV is among the most pristine spacecraft ever flown. Europe’s space freighter underwent a rigorous cleaning process to ensure the safety and comfort of the ISS crew upon its arrival in orbit.

“It’s an often overlooked activity, but an essential one,” explained Arnaud Runge, biomedical engineer, part of ESA’s ‘ATV Disinfection, Cleanliness and Contamination Control’ team with Pierre Rebeyre chemist & Stephanie Raffestin microbiologist. One priority for the disinfection team has been to minimise microbial contamination – bacteria, viruses and fungi – within the spacecraft, especially considering that astronauts’ immune systems end up weakened by long-duration stays in space.”

In addition the ATV had to be kept clear of particulates both inside and outside. Exterior dust could have degraded instruments, such as the lasers helping to guide the automated docking process, while sharp-edged particles set floating internally in microgravity can be inhaled or caught up in eyes.

Last but not least, the many dozens of payloads that were crammed aboard the ATV had to be checked to see that they do not give off harmful ‘volatile organic compounds’ (VOCs) over the course of the spacecraft’s journey to the Station, as well as no potential dangerous micro-organisms.

Disinfection and Cleanliness campaigns have been carried out for all five of the spacecraft, with specialists from ESA’s Directorate of Technical and Quality Management working alongside the ATV programme team, Arianespace, Airbus and other ISS partner nations.

The procedures being followed have been continuously improved. So, for instance, while the workers outfitting ATV-1 dressed simply in gowns and hairnets, fully-covering ‘bunny suits’ incorporating face masks had to be worn by everyone coming within a set distance of ATV-5.

This is essential because the human body is itself a significant source of contamination: in the form of breath and sweat expelling microflora, as well as shedding hair and skin cells. People are even known to directly exhale harmful compounds such as formaldehyde.

Microbial cleaning

Microbial organisms reaching the closed environment of the Station would have posed a risk to crewmen and also, potentially, to structural elements. Russia’s Mir space station, towards the end of its 15-year lifespan, suffered an acid-producing fungal infection corroding plastic, glass and titanium surfaces.

ATV is of course manufactured and outfitted in cleanroom surroundings, but some bacteria, viruses and fungi inevitably make it through.

The disinfection team at the launch site in French Guiana track ‘bioburden’ levels by exposing ”contact plates” (i.e. Petri Dishes covered in nutrient gel) for 30 seconds beside a surface to be cleaned or by swabbing. Swabs are additionally wielded, to check cargo bags and operator gowns.

“These samples are then incubated at our partner, the Pasteur Institute in Cayenne,” explains Stéphanie.

“Within five to seven days microbial colonies growing in the petri dishes are counted to assess the extent of microbial contamination. Recovered microorganisms are then identified (DNA sequencing) in order to confirm their nature and the absence of pathogens.

“Meanwhile the disinfection process is carried out using 6% sterile hydrogen peroxide (H202)-water solution. Also widely used in hospitals H202 has the advantage of rapidly breaking down into oxygen and water, so there is no chemical residue and it preserves the integrity of equipment.

“Follow-up sampling is then performed to check the disinfection process has been effective – typically it has.”

The team disinfects and monitors all European cargo bags being flown on the ATV. This entire operation is repeated in the event they are reopened to add last-minute payloads.

While other international partners typically test their own payloads, Japanese space agency JAXA also has ESA test their cargo bags, while Russia’s Institute for Bio-Medical Problems also performs some parallel checks on European cargo bags.

Controlling particulates

What we call ‘foreign object debris’ might be previous residues from machining, or contamination from the external environment. Plus, the processing of loading the spacecraft might also produce fresh particulates – such the residual metals or debris loosened by screwing adapter plates in place.

The particulate control team follows common ‘Space Station Programme’ requirements detailing the acceptable conditions of habitable internal ISS surfaces as well as air quality.

Surfaces were subjected to a close-up visual inspection at a set distance and angle, backed up by bright lighting, to ensure surfaces are contamination-free to a set ‘visibly clean – sensitive’ level.

Crucial outside surfaces were checked to an equivalent level, including all optical instruments – such as laser range finders as well as star trackers – on-board thrusters and the docking system with ISS: any layer of dust might have prevented a solid seal from forming.

Air cleanliness requirements, enforced by regular air sampling, were stricter still: less than 0.15 milligrams of particles per cubic metre of air – a tiny fraction of a single grain of sand – within the 0.5 to 300 micrometres range. This is equivalent to smoke sized and upwards, with mid-sized particles causing greatest concern.

Once identified, any particulates were removed in various ways, starting from small-scale wiping and vacuuming up to flushing and replacing all the air within the ATV and surrounding launch fairing.

All activity on the ATV was precisely logged, to identify any potential risk of fresh particulate contamination. Workers are required to inspect themselves, and door opening times are minimised. Insect traps and insecticide help ensure no living particles made it into the spacecraft from the tropical humidity outside.

One final cleanliness inspection was carried out before the late-loading vertical ATV hatch was closed for good, with a worker and camera lowered down on a hoist that had itself been thoroughly cleaned first.

Air toxicity

All materials other than metals give off fumes over time – think of the distinctive smell of a new car. The problem is, above certain concentrations, these ‘volatile organic compounds’ might actually be hazardous depending on their nature and concentration, especially for the astronauts charged with opening the ATV up at the ISS.

“Individual payloads are tested for what we term ‘offgassing’,” explains Thomas Rohr, overseeing ATV’s air quality effort.

“That involves placing them in an oven filled with synthetic air, warming them up to about 50 ° C for a three day period, to accelerate the offgassing process, then sampling the surrounding air with an absorption thread of activated carbon. This captures any molecular contaminants that can then be analysed via gas chromatography.”

“That involves placing them in an oven filled with synthetic air, warming them up to about 50 ° C for a three day period, to accelerate the offgassing process, then sampling the surrounding air with an absorption thread of activated carbon. This captures any molecular contaminants that can then be analysed via gas chromatography.”

Any payloads that fail their initial test are retested – the repeated heating process typically serving to bake any remaining contaminants. ESA typically tests all European payloads, with the other international partners having responsibility for their own.

“The challenge is that while the payloads are compliant individually, all the offgassing constituents of the entire densely-packed cargo module – just about 70 cubic metres in all – may still add up to a slightly unpleasant or unhealthy environment,” adds Thomas.

“We wanted to ensure that when astronauts open the hatch they were not exposed to any risk.”

Considering the ATV docked to the Russian segment of the ISS but most cargo was transported to the US segment both Russian and US toxicity standards were adhered to, along with common ‘interface rules’ for air quality. Examples of unwanted VOCs include methanol, formaldehyde and acrolein.

Air samples were taken throughout initial ATV loading, then once the hatch was closed sophisticated modelling predicted how VOCs would be released.

When the hatch was opened again for last-minute loading, the model could be compared to observed reality.

Finally the existing air was cycled and replaced with new synthetic air – which was sourced directly from tanks of oxygen and helium rather than the outside atmosphere – a few days before the 29 July 2014 launch.

Once launched, the ATV was in flight for 14 days before docking. The offgassing model was applied to predict likely VOC concentrations over the course of the voyage.

Finally, after ATV docked, the astronauts sampled the air quality through the airlock without opening it. The air scrubber was used to clean the air for a few hours before entering.

“Once out of the close-quarters of the ATV, offgassing is less of an issue in the approximately 1000 cubic metre atmosphere of the overall ISS,” says Thomas.

“Plus the Station’s Environmental Control and Life Support System does a very good job scrubbing contaminants from the air.”

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

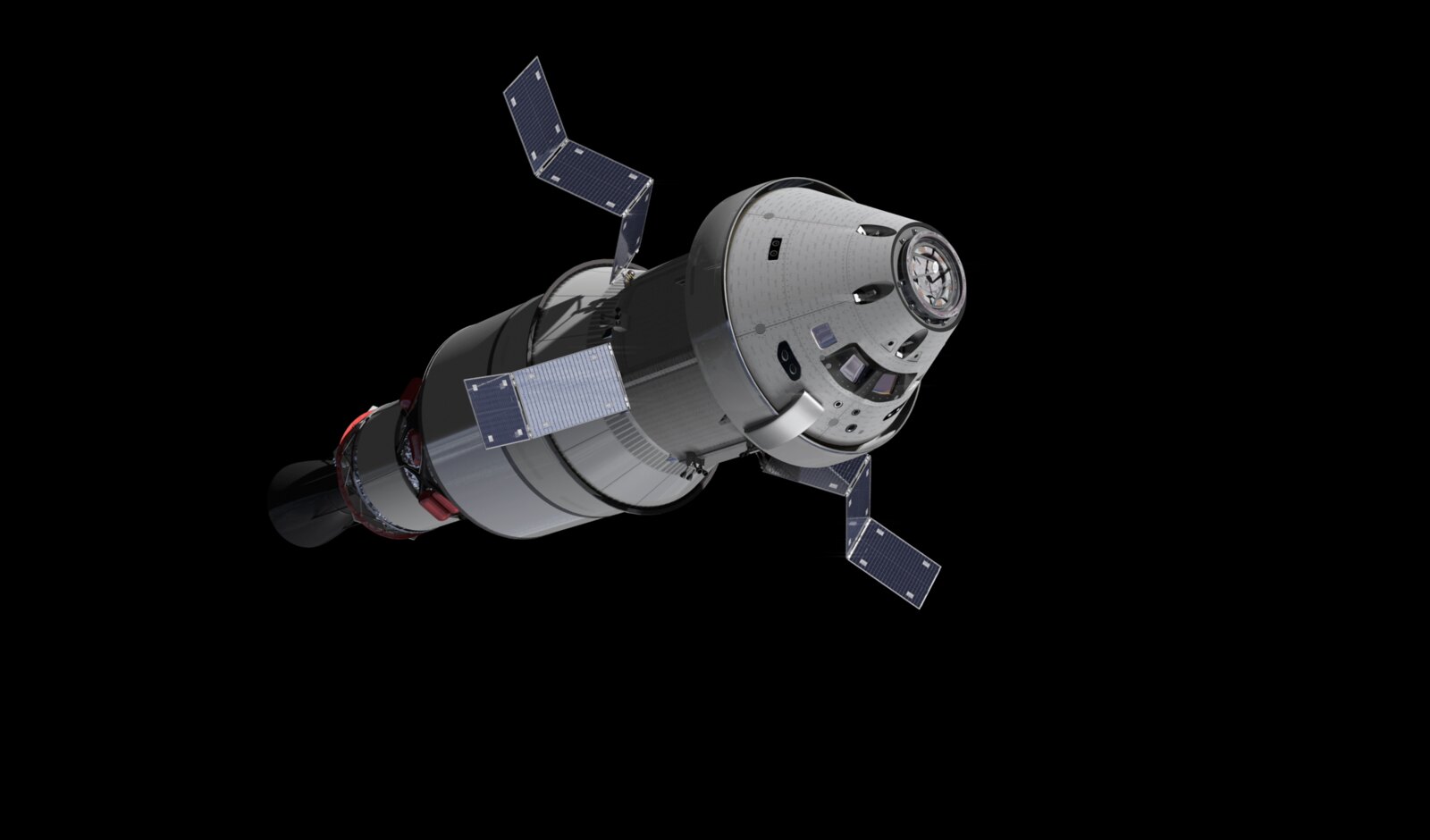

NASA Orion page

NASA Orion page NASA Artemis

NASA Artemis Airbus Orion page

Airbus Orion page

Discussion: one comment

dressed simply in gowns and hairnets, fully-covering ‘bunny suits’ incorporating face masks had to be