Continuing our series on country-level contributions to ATV, let’s look at Switzerland.

In the case of ATV-4, the first connection is naturally the name: Albert Einstein, who was born in Ulm, Germany, but who studied and spent his early career in Switzerland.

In the case of ATV-4, the first connection is naturally the name: Albert Einstein, who was born in Ulm, Germany, but who studied and spent his early career in Switzerland.

He got a job in Bern at the patent office and there had time to ponder the problems of physics, leading to four fundamental scientific papers on the photoelectric effect, Brownian motion, special relativity, and the equivalence of matter and energy – all in 1905. These raised Albert to fame even beyond the scientific community, and today we can consider Einstein’s career and findings as the fruit of cooperation between many countries – just as ATV is.

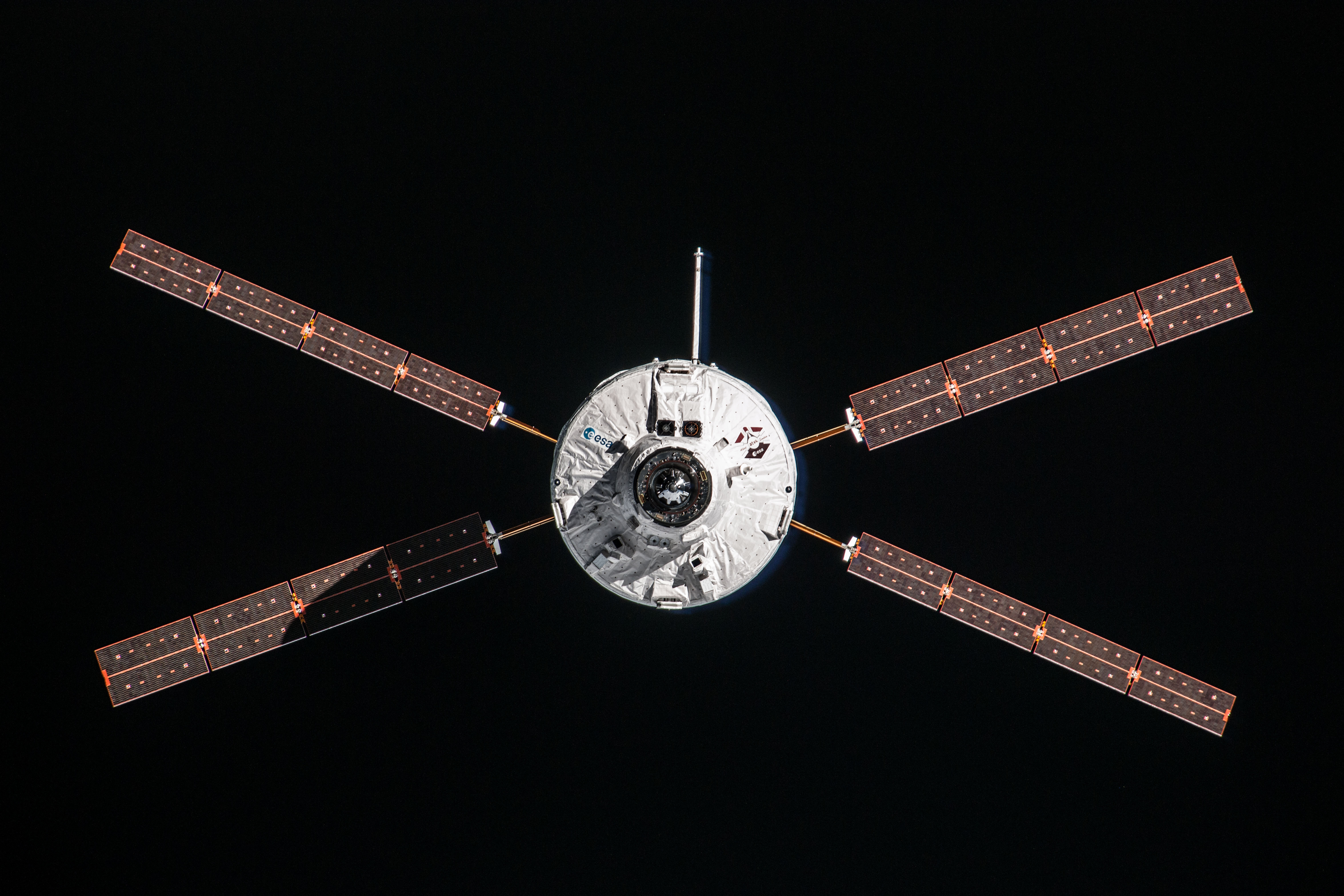

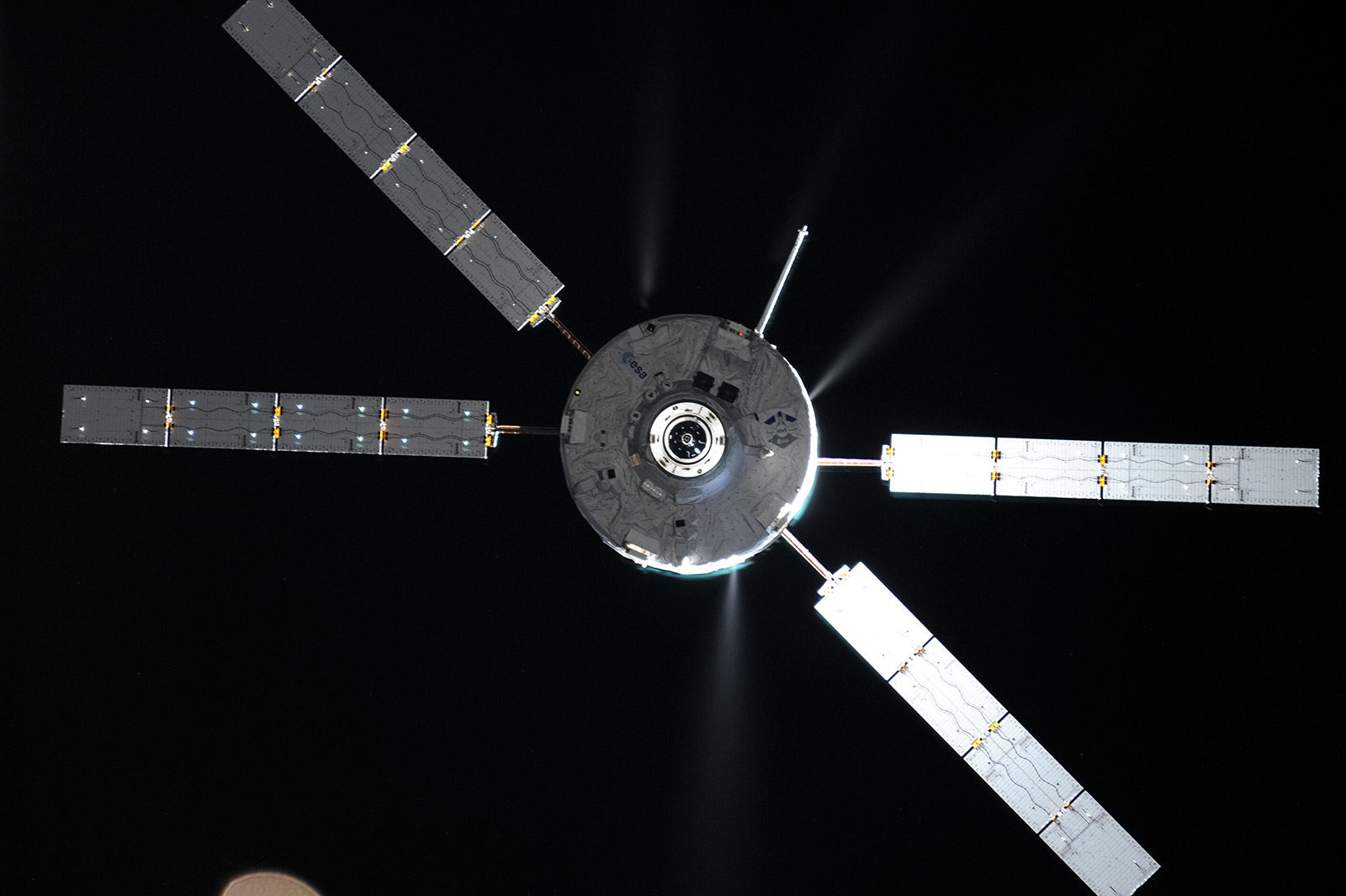

Ruag space, based in Zurich, contributed the basic structural elements of ATV’s propulsion module and the cargo racks inside the pressurised module. These are not to be taken lightly, even though they are designed to be as light as possible. In spaceflight, weight equals cost as more fuel is needed to propel heavier objects into orbit.

Ruag space, based in Zurich, contributed the basic structural elements of ATV’s propulsion module and the cargo racks inside the pressurised module. These are not to be taken lightly, even though they are designed to be as light as possible. In spaceflight, weight equals cost as more fuel is needed to propel heavier objects into orbit.

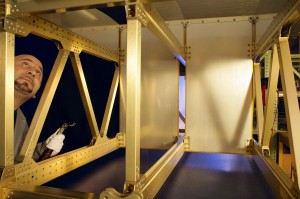

The racks that hold ATV’s cargo are made of aluminium and comply with NASA’s standard sizes: the Internal Subrack Interface Standard and the Mid Deck Locker. Weighing just 92 kg, Ruag’s racks can hold 750 kg of equipment and will still stand strong after enduring acceleration of more than 12.5 g (12.5 times the pull of gravity on Earth). This means that up 9375 kg can be supported by just 92 kg of structure, slightly more sturdy than your bookshelf!

The racks that hold ATV’s cargo are made of aluminium and comply with NASA’s standard sizes: the Internal Subrack Interface Standard and the Mid Deck Locker. Weighing just 92 kg, Ruag’s racks can hold 750 kg of equipment and will still stand strong after enduring acceleration of more than 12.5 g (12.5 times the pull of gravity on Earth). This means that up 9375 kg can be supported by just 92 kg of structure, slightly more sturdy than your bookshelf!

Ruag also supplied the Solar Array Deployment Mechanism, the equipment that unfolds the solar panels after launch. They were not chosen at random, their ‘sun-panel deployer’ proved itself on the Hubble telescope in 1990.

A regular star of this blog was also made in Switzerland: the LCAM or Late Cargo Access Means that allows cargo to be added to an ATV just before launch. Apco, based in Vevey near Lausanne, took care of the MGSE or Mechanical Ground Support Equipment on ATV.

A regular star of this blog was also made in Switzerland: the LCAM or Late Cargo Access Means that allows cargo to be added to an ATV just before launch. Apco, based in Vevey near Lausanne, took care of the MGSE or Mechanical Ground Support Equipment on ATV.

In addition, Apco supplied ATV’s armoured coating, protecting the precious spacecraft from meteorites and space debris. In space terms, this is called the MDPS (Meteorite and Debris Protection Shield), an acronym that is surprisingly easy to understand.

Micro-meteorites and space debris are no joke: travelling at speeds of up to 72 km per second, even the impact of a flick of dried paint can have serious effects. ATV uses something called a Whipple Shield, which is a layer of metal placed at a distance from ATV’s interior structure. This shield acts like a bumper wall, forcing the incoming particles to disintegrate and spreading out the impact over a larger area of the inner wall of the spacecraft. This stops anything from penetrating to the critical mission hardware.

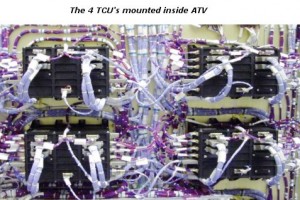

Lastly SYDERAL, based in Bern, provides four thermal control units to keep ATV operating at optimum temperature. The units monitor and control the batteries and report directly to ATV’s platform computer. The system is designed to be failsafe and has multiple redundancies, which is why SYDERAL supplies four of the units for each ATV.

Lastly SYDERAL, based in Bern, provides four thermal control units to keep ATV operating at optimum temperature. The units monitor and control the batteries and report directly to ATV’s platform computer. The system is designed to be failsafe and has multiple redundancies, which is why SYDERAL supplies four of the units for each ATV.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

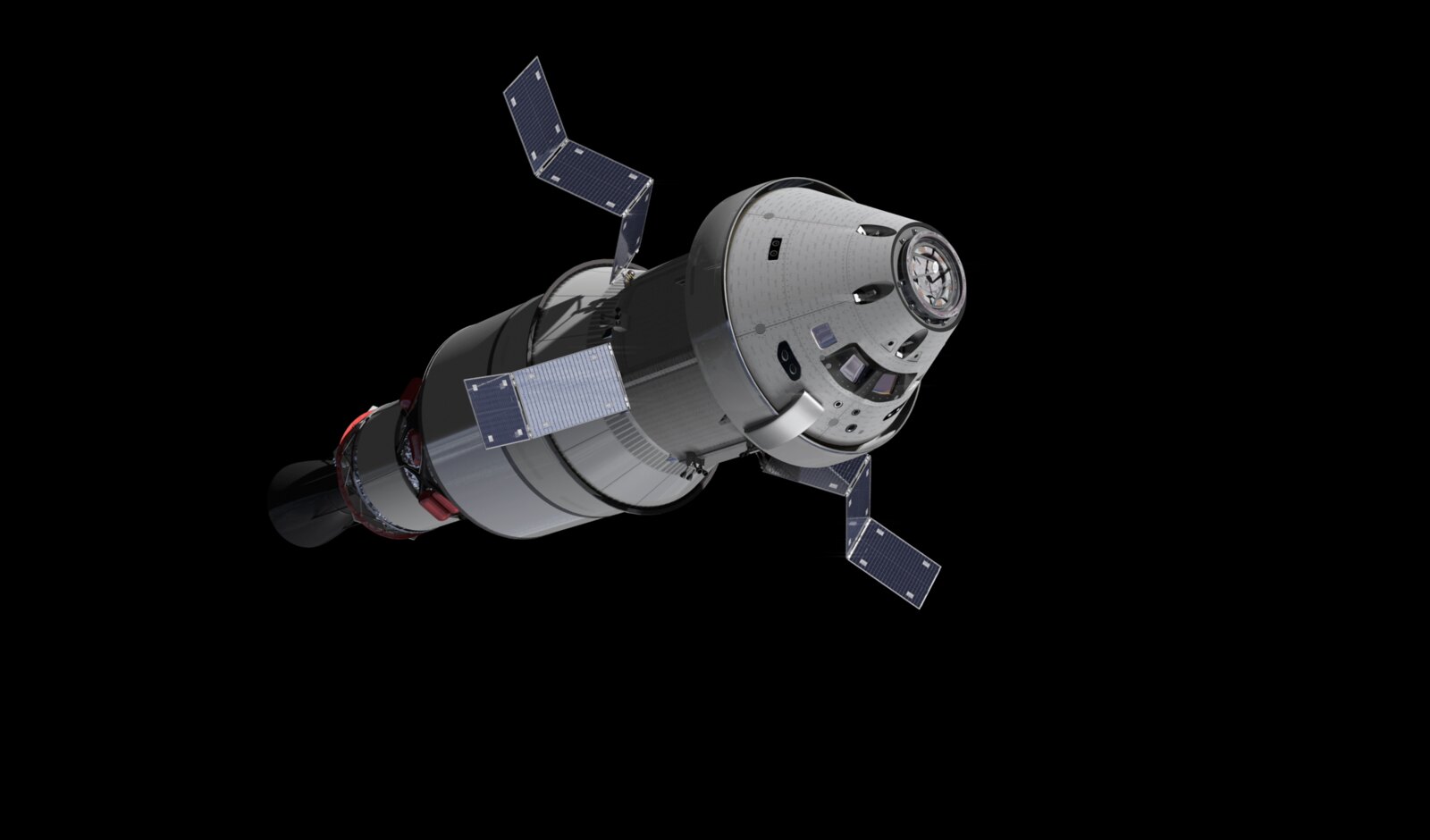

NASA Orion page

NASA Orion page NASA Artemis

NASA Artemis Airbus Orion page

Airbus Orion page

Discussion: no comments