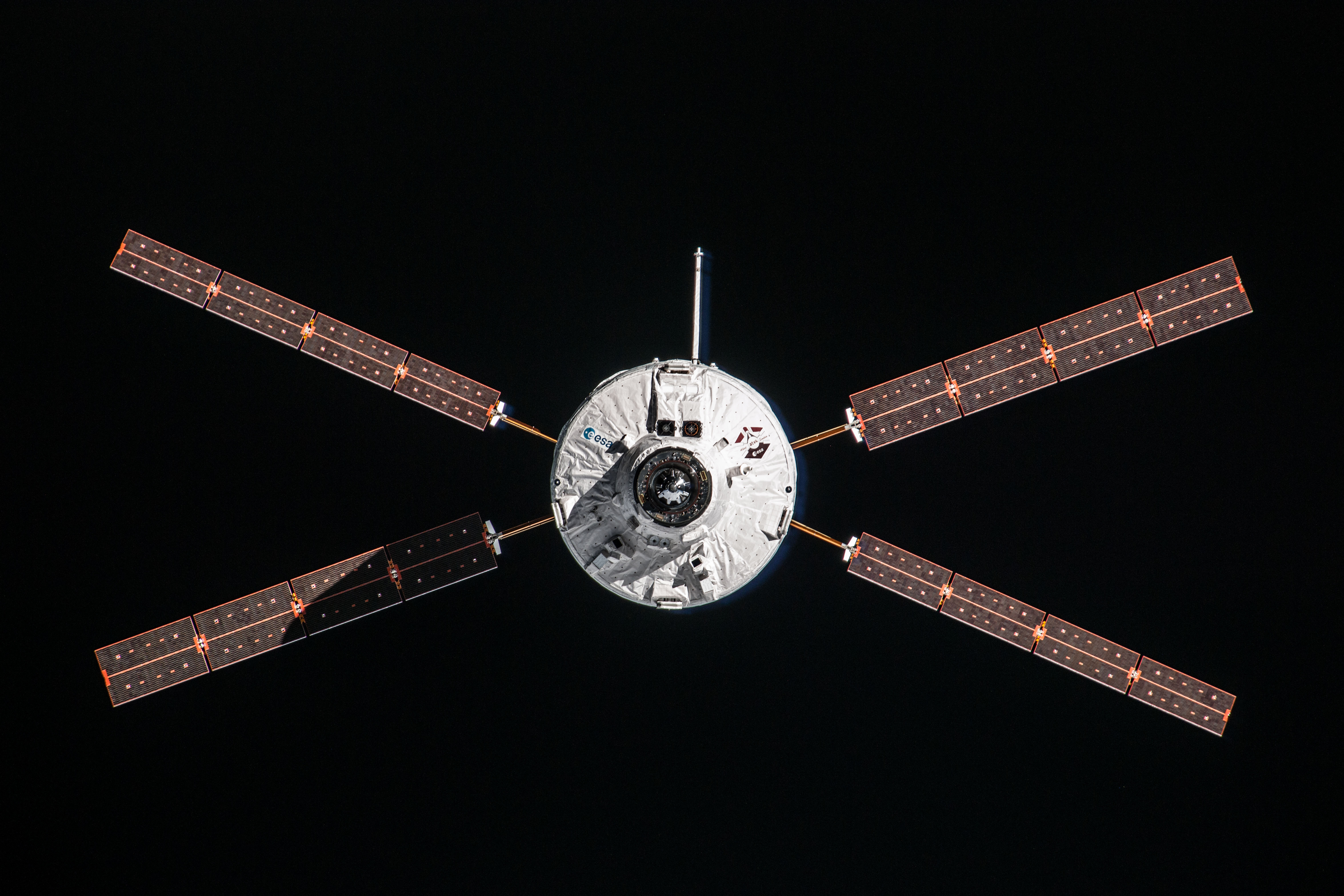

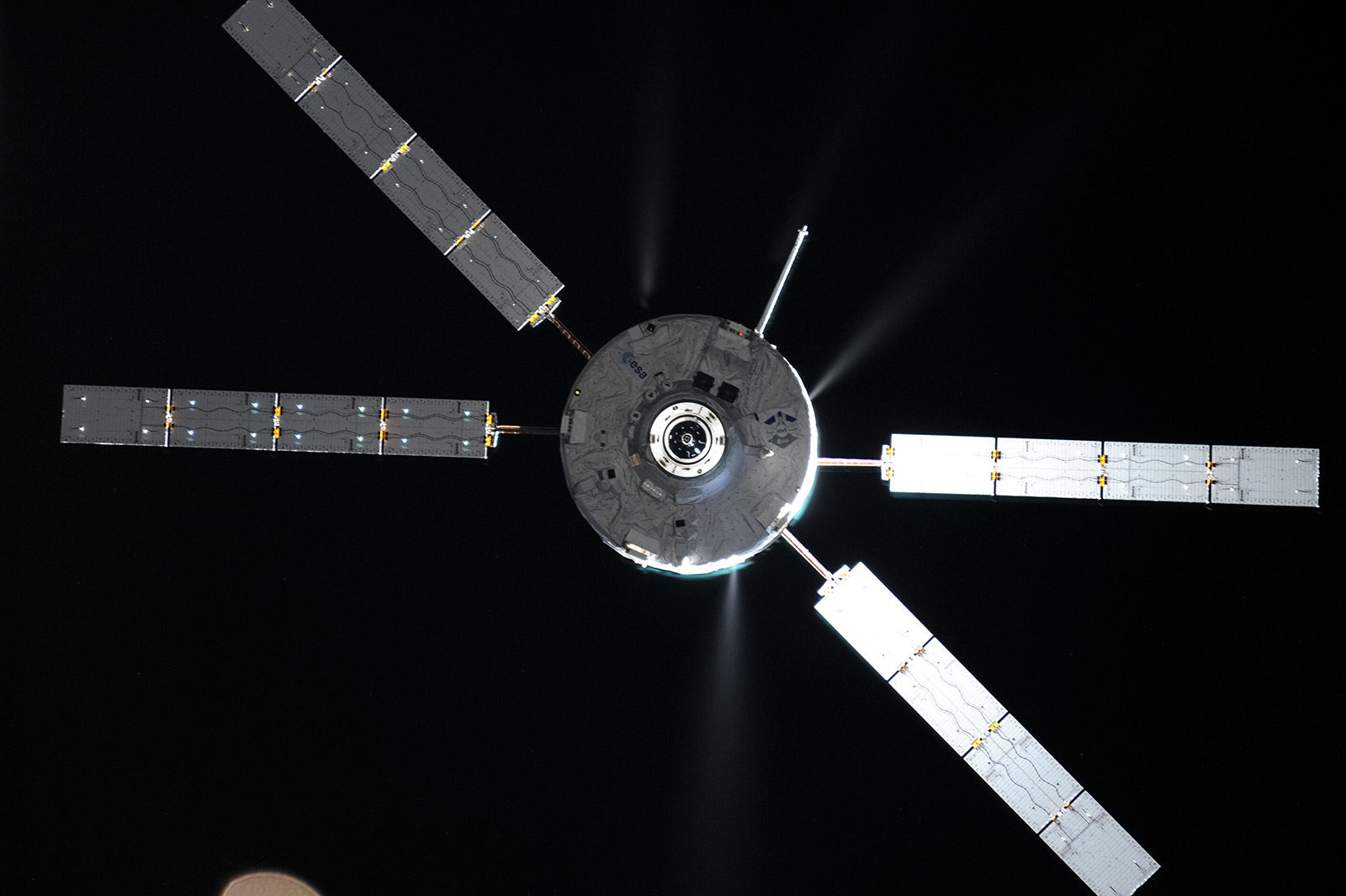

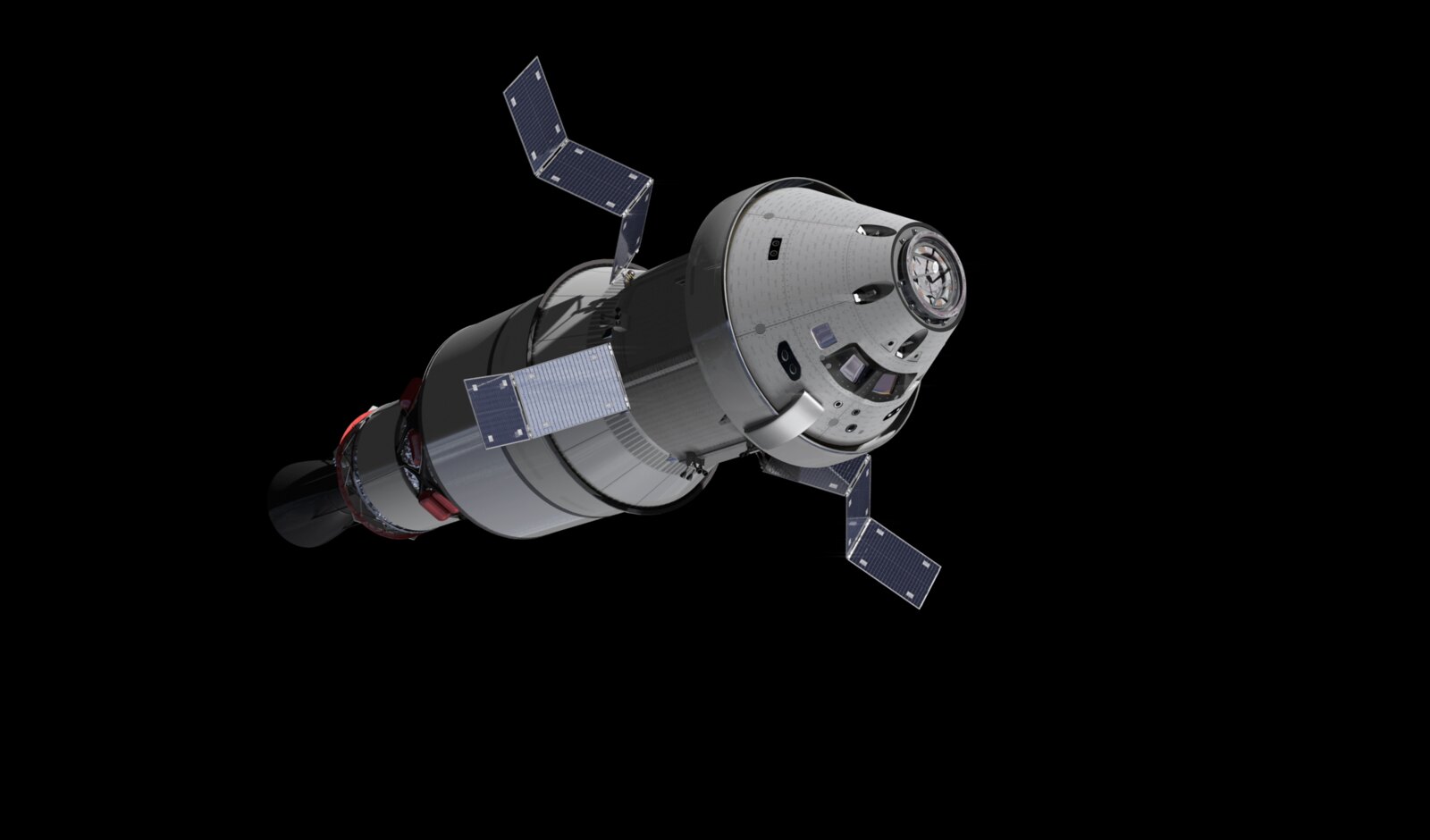

The first rule of DIY: know where your tools are. Astronauts on the International Space Station are about to have that task made a lot more simple, with a purpose-designed 3D-printed toolbox due for launch today on ESA’s latest ATV resupply spacecraft.

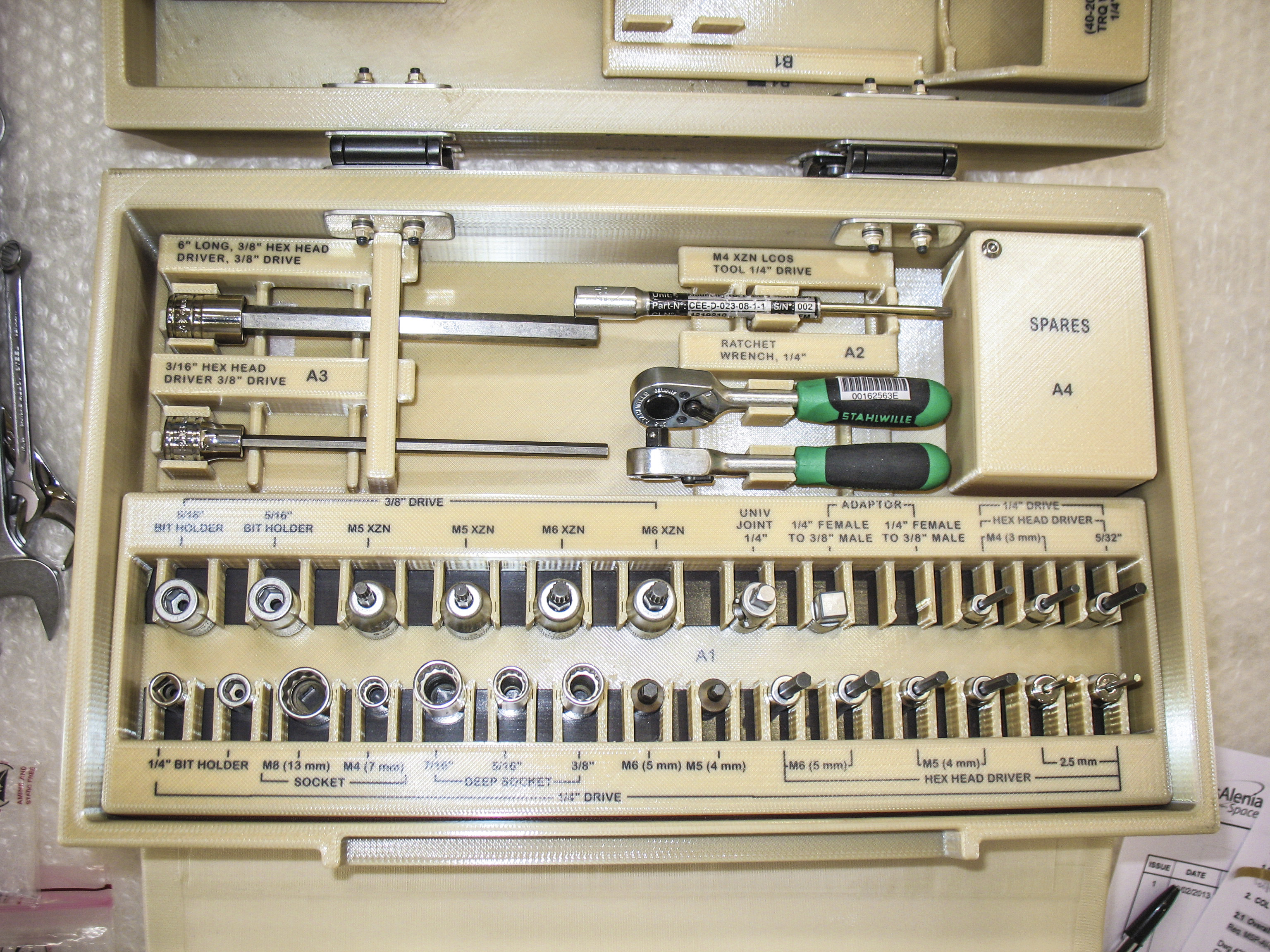

This purpose-designed 3D-printed toolbox is being launched to the ISS on ESA’s latest ATV resupply spacecraft. The strong, lightweight multitray toolbox was printed in ULTEM 9085 thermoplastic by Thales Alenia Space in Turin through an ESA contract. The toolbox is designed to store tools for maintaining Europe’s Columbus research module. The new toolbox includes little clips to hold the tools in place, just like toolboxes you can buy at a hardware store, instead of the previous Velcro inserts that may lose their stickiness over time. At the same time, the toolbox exterior still has Velcro covering, so astronauts can leave it in place while they work without it drifting away. If any part of the toolbox breaks then the ground has only to reprint and fly up the tray in question. Following this pilot project, future long-duration missions could carry their own 3D printers in space to print out failed parts immediately.

The strong, lightweight multitray toolbox was printed in ULTEM 9085 thermoplastic by Thales Alenia Space in Turin through an ESA contract.

It was then tested by labs in ESA’s ESTEC technical centre in Noordwijk, the Netherlands, for ‘offgassing’ – the release of potentially harmful vapours in the closed environment of the Space Station – to be sure it is safe for use in orbit.

“The toolbox is designed to store tools for maintaining Europe’s Columbus research module,” explains ESA’s project leader, Bram Bekooy.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: no comments