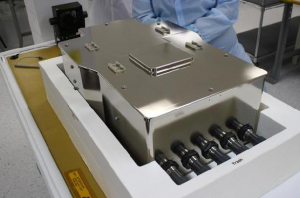

Perhaps the most valuable cargo on ATV-3 is the Fluids Control Pump Assembly (FCPA). This is a critical piece of the system that recycles urine into drinkable water, and that could affect the ISS life support systems.

Right now, there is an FCPA in use but no spare available on the ISS. If it breaks down, the astronauts would still have enough water for some time, but the Station wouldn’t work at full efficiency.

NASA decided to send a replacement as soon as possible and alerted the ATV-3 cargo planners to reserve a space for the water processing unit. There was one caveat: the machine would not be ready for loading until shortly before launch, raising the critical question: Would it even be possible to load it last-minute?

Usually all cargo is loaded on the ATV from the ‘back’ of the Integrate Cargo Carrier (ICC) – before the systems and propulsion module is attached.

Once ATV has been assembled the only way to access the cargo space is through the (small) main hatch, the same one used by astronauts on the ISS. Normally cargo loaded this way is restricted to a standard Double-sized Cargo Transfer Bag (CTB), measuring 49 x 42 x 50 cm and with a maximum mass of 25 kg. Also, cargo is normally loaded into rack sectors, or ‘shelves.’

Moving a large, 50-kg water processing unit in space requires skill and precision, while on Earth gravity becomes an extra force to contend with.

In addition, the unit is too big to be loaded inside a rack, so it must be loaded in one of the large M-01 bags that are mounted on Adapter Plates to the front of the racks. Although the contents of an M-01 bag must fit through ATV’s hatch, the bag itself does not. Luckily NASA had given the ATV team a few months’ warning, so the team set down to tackle the problem.

Reserving the space for the water processing unit was easy. An M-01 bag was earmarked and placed in the ATV. Can you spot the empty bag in the picture below?

A full scale mock-up of the ATV in launch position had just been built in Switzerland (to test a new last-minute loading crane which will be used on ATV-4). Although the crane would not be ready for this launch, the mock-up did give the team a good environment to practice lowering and stowing the water processing unit for ATV-3.

Loading the water unit requires opening the M-01 bag and undoing the straps. However these straps also keep the bags secured to the Adapter Plate mounted on the front of the rack. The platform that lowers the engineer is not wide enough to support the bag when unclipped. Therefore, a sling was designed to carry the load of the bag when unstrapped.

One problem encountered during the practice runs was that the sling did not prevent the bag from sliding out of the retaining fence on the Adapter Plate. This meant that the bag started to sag leaving a gap between the stowage and its temporary support. A simple but effective solution was found: insert a wedge to hold everything up.

Left: Gap between the M-01 bag and its support. Right: The wedge used to fill the gap Credits: ESA / K MacDonell

After a few simulations the ATV team were able to master the new process and are ready to load the water unit for real, in Kourou, just prior to next month’s launch. They will be travelling to Kourou next week where the finished water processing unit will be flown in from Houston.

We are sure the astronauts in space will ‘appreciate’ (if that’s the right word!) efforts made on Earth so that they can drink their processed urine.

Yes, ATV-3 will bring 285 litres of fresh water – but recycling (and having a back-up unit in orbit) is always a good thing!

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

Discussion: one comment

I agree with you