ATV toxicity team report

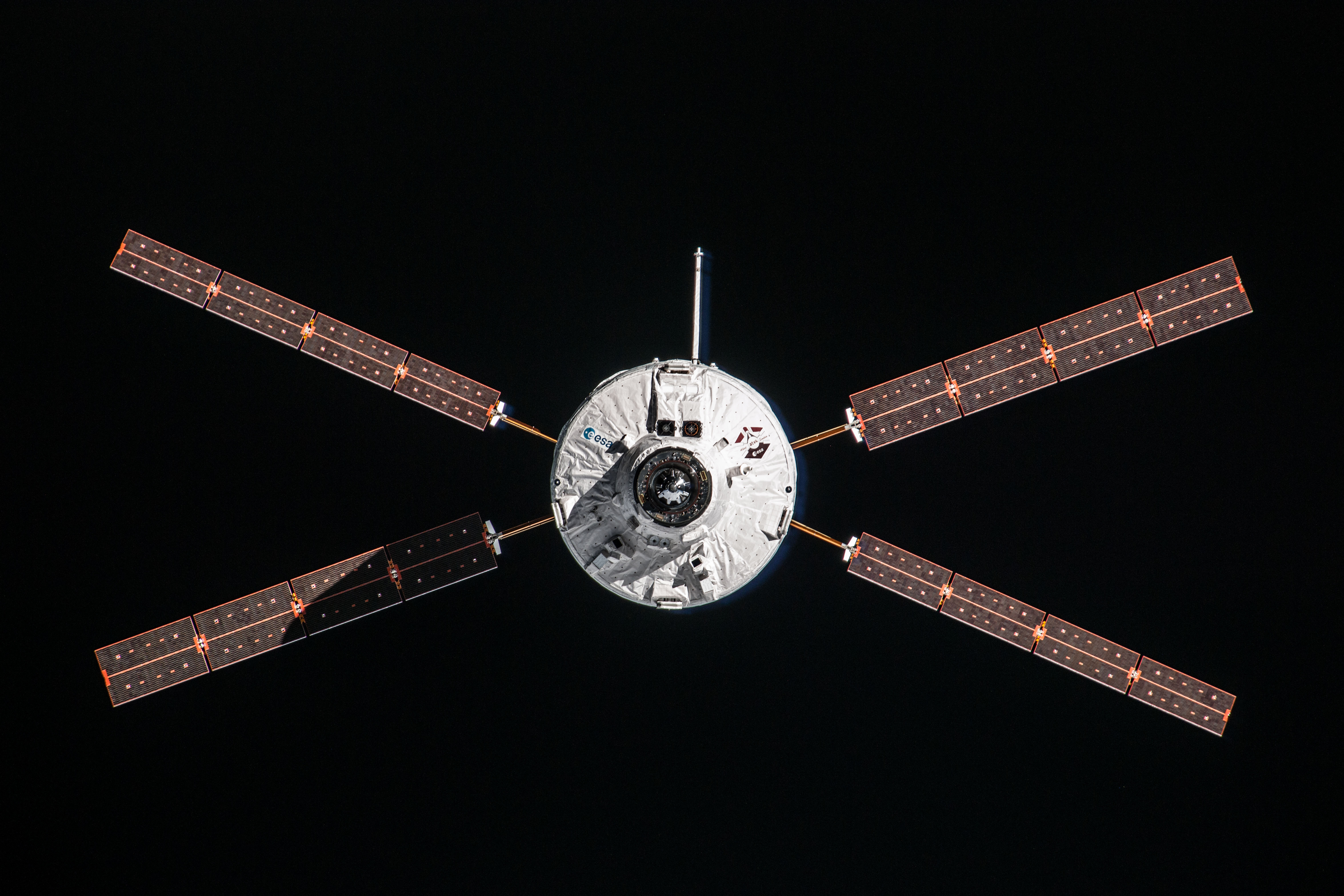

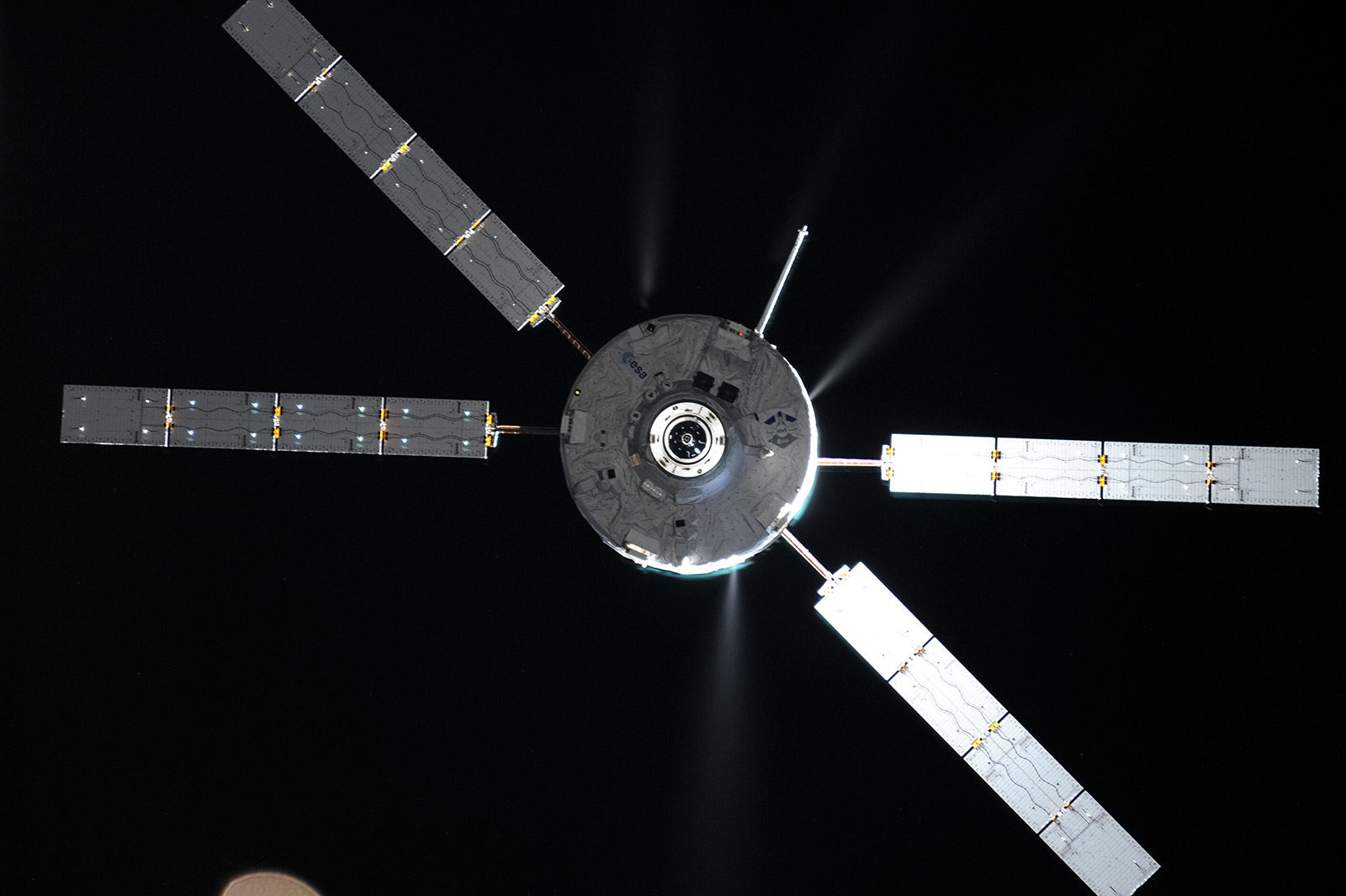

Editor’s note: The story of the ATV missions to the ISS involves not only grand happenings – lift-offs, orbitings, dockings and bitter-sweet endings – but also many small, seemingly mundane, steps carried out diligently by dedicated, passionate people. One of these involves a team of ESA experts working along side the cargo loading and fuelling engineers and technicians at Kourou – but ‘behind the scenes’ – to ensure that the air inside ATV meets all the required standards before docking to the ISS.

Of course, when it comes to docking and delivering cargo, crew safety is paramount. And, yes, there are standards for more or less everything on board the ISS – including the atmosphere inside Station and inside ATV. After the docking, the hatch opens, and the cargo vessel becomes an integral part of Station. At that point, the two atmospheres mix freely, and there had better not be any gas or particulate matter suspended in the ATV air that could affect the crew or the Station.

Where does toxic gas come from? Think of the last time you slid into the driver’s seat of a show-room car – we all know that ‘new-car smell’. It’s a mixture of gases that are emitted from the numerous interior fittings in a car: the leather seats, paint and coatings, the multiple types of plastic used in the dash and in the interior fittings, the carpets, etc. It’s the same with each new ATV – out-gassing can cause air toxicity in the enclosed cargo volume.

Likewise, there had better not be any physical contamination on the exterior of ATV that could affect its performance – image the problems if a greasy thumbprint were to be left unknowingly on the optics of one of the laser docking telegnometers.

For a number of weeks, ESA engineers Mei Mei Stienstra and Olivier Schmeitzky, based at ESA’s ESTEC technical centre in The Netherlands, have been working in Kourou to verify the air inside ATV and check the vessel overall for contamination. They’ve been conducting tests and checks at numerous stages – including during and after main cargo loading, after the two halves of the vessel were integrated, and after the late cargo load, which finished last week (ATV Edoardo Amaldi’s hatch was closed on 16 February).

ATV-3 toxicity team at Kourou. L-R: Dimitry Tsarkov (IBMP Moscow), Olivier Schmeitzky (ESA/ESTEC), Mei Mei Stienstra (ESA/ESTEC) Credit: ESA/A. Novelli

In a telephone interview last Friday, I had a chance to ask the two about their crucial work. Mei Mei works on gases, while Olivier focuses on particulate matter both inside and on outside surfaces (including the crucial laser optics) of ATV. Here’s a rough transcript of our call.

Mei Mei:

We sample the air inside ATV at various stages, and conduct toxicity analysis on the samples. We’re looking for chemical contamination: off-gassing from the interior components or cargo, like alcohols or benzene. Everything releases low amounts of something, and in an enclosed space, these could build up to affect the crew. This isn’t new; the same was done for ATV-1 and -2.

Basically, we feed a plastic tube into ATV and then pump out a few litres of air – that’s the sample. The analysis is done back at ESA/ESTEC. We check several times after each cargo load is installed – we collect samples up to seven days after the main cargo is integrated and up to six days after ‘late-load’ cargo loading finishes.

For ATV-3, we are looking good! Forty-six days after the main cargo load, we found ca. 36 mg/m3 of chemical contaminants and were within the toxicity specification for ATV-3. We use the data from all samples taken after main and late access cargo loading to make a prediction of the final toxicity level when ATV-3 will dock to the ISS. For the toxicity assessment, we apply Spacecraft Maximum Allowable Concentrations (SMAC) levels that NASA has specified. NASA in fact was here for the launch of ATV-1 in 2008, but since then, we do it independently and simply report our values to NASA.

We are also joined in our testing by Dimitry Tsarkov, from Moscow’s Institute for Biological and Medical Problems (IBMP – site of the Mars500 isolation study), who is working in support of Roscosmos. Since we dock to the Russian module, Dimitry is performing sampling in parallel with us to calculate the equivalent Russian toxicity values. For ATV-3, while we still have to perform the final analysis from some of the post-late-load samples, we are good for launch.

Yes, we also do similar contamination testing for ESA’s robotic satellites, but it’s much more timely and critical for ATV, since it’s a human-rated vessel.

Olivier:

There are basically two main areas to check for physical or particulate contamination: the atmosphere and surfaces inside the ATV, and the vessels external surfaces – especially the optics, like the star trackers and the lasers. We look for macro debris anywhere – bits and pieces of anything that might have become loose due to vibration or scratching. We especially look in the interior for small particles – metal filings, manufacturing debris, paint flakes, bits and pieces of anything, really – as these could be really dangerous.

On Earth, gravity ensures that such tiny items remain lodged wherever they fell and they may not be so problematic; but in orbit, there’s nothing to hold them in place and they float around in the cabin. Some small metallic item could interfere with electronics or even be inhaled by an astronaut, which could really be dangerous. So, we have to be pretty thorough.

We (ESA) started this sort of work with the Columbus lab that was attached to the station in 2008. At that time, we had support from NASA – to learn how to do it. NASA also performed their own checks for ATV-1 and -2. Now, we have built up this capability and expertise in Europe and NASA simply accepts our reports. We have to ensure that ATV’s air meets ISS standards in terms of No. or particles/m3.

ATV-3 is looking good for flight! We have so far found a few small items – micro debris up to 1 cm in size. But overall, we’re fine. ATV-3 is actually having better results than ATV-2; the manufacturing and cargo loading processes are getting better, which is to be expected. We’ll probably de even better for ATV-4.

Just before closing the hatch, we pumped extremely clean air into ATV, blowing out any remaining particles. When the astros open the hatch in space, part of the ingress process is to check for particle contamination inside ATV. You’ll see them wearing face masks and eye protection for the first few minutes. If they do not notice flying debris, they’ll unmask and proceed with further activity.

Now that the hatch is closed, we’ll spend some time vacuuming the exterior of ATV to clear off anything sitting on the external surfaces. This is usually very effective – it removes paint chips, human hair, any sort of micro debris, really.

The final step will be done as part of lowering the Ariane 5 aerodynamic fairing – the rocket nose – over ATV. We’ll blow air all around it to keep it dry and cool as the fairing is lowered. That will happen on 27 February as part of encapsulation.

Automated Transfer Vehicle page

Automated Transfer Vehicle page ATV blog archive

ATV blog archive

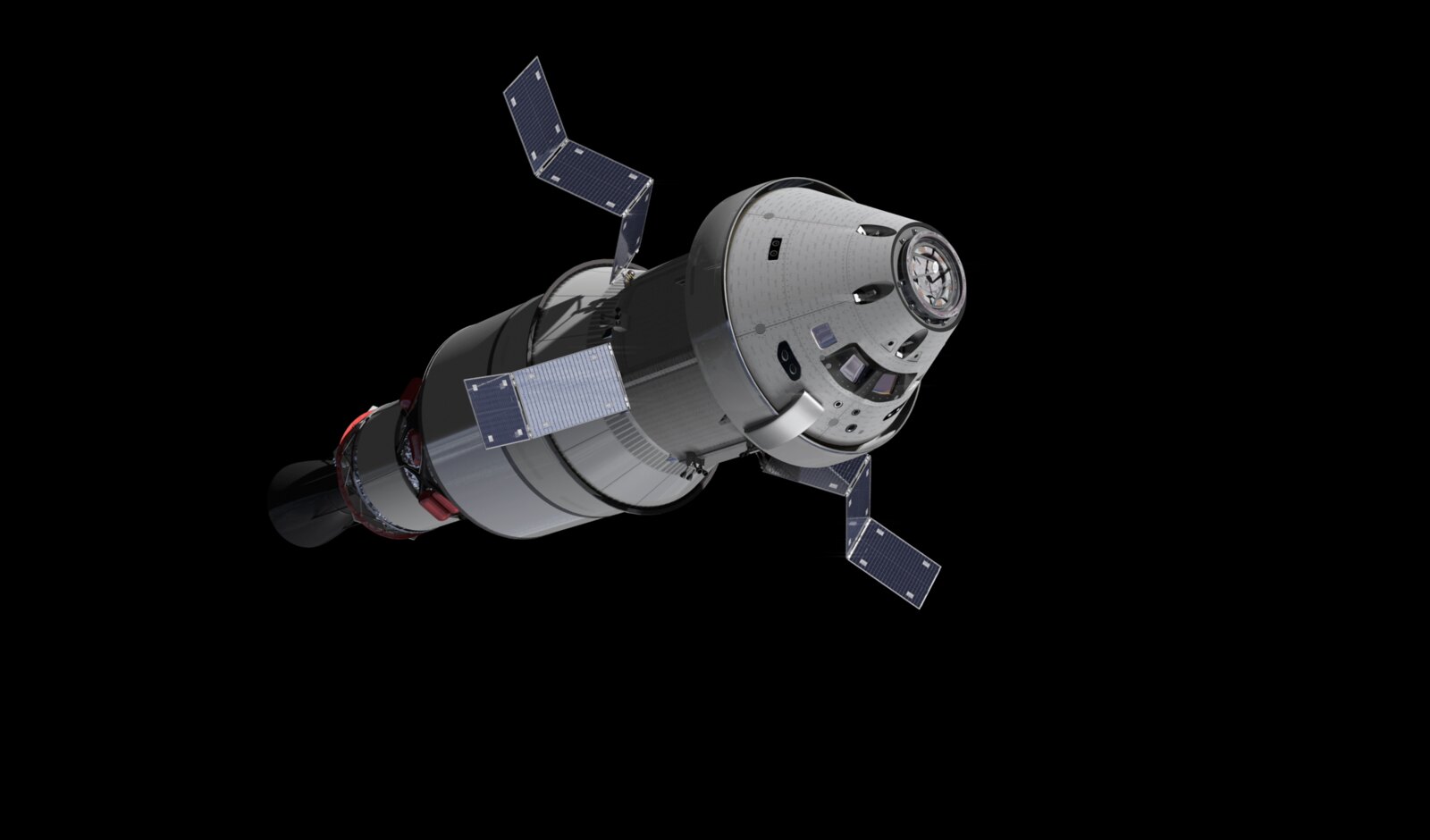

NASA Orion page

NASA Orion page NASA Artemis

NASA Artemis Airbus Orion page

Airbus Orion page

Discussion: no comments